A renewed emphasis on solar module quality raises the question of how quality is evaluated.

Module manufacturers are only required to meet the UL and or IEC safety standard. “Everything else is imposed by developers and financial institutions that require not only long-term performance guarantees, but also reliability guarantees.”

Renewable Energy Testing Center (RETC) Engineering and Operations Senior VP Cherif Kedir explained his company’s procedures.

“We have different programs,” Kedir said, “depending on what [companies] want to accomplish.”

The banks, Kedir explained, are concerned about the return on their investment. “If a project is supposed to turn profitable after seven years, they want to make sure that is going to happen after seven years and not eight or nine years.”

Developers are more interested in the shorter term, he said, “unless they are planning on holding the development.”

But between the two, “they end up getting the whole gamut of tests, because each has slightly different needs and they don’t want to concede them.”

Once the manufacturer, the developer and the financing institution develop a working relationship, Kedir added, there is less demand for testing.

“The basic performance validation we do is modeled against the IEC 61853 standard,” Kedir said. “The next level is the reliability tests.”

Performance testing ensures that the panels a manufacturer ships perform according to their claims. An RETC report affirms that the product, Kedir said, “will perform in the field the way it is expected to.”

RETC performance tests measure how much power the modules will deliver under different light and temperature conditions. “We test at 15 degrees C, 25 degrees C, and 75 degrees C. and we measure at between 100 watts and 1,100 watts per square meter.”

The last part of performance testing is for light-induced degradation (LID). “We take a set of panels, measure the power output at standard test conditions [STC] of 25 degrees C and 1,000 watts per square meter, and then light-soak them outdoors or in simulated light and keep measuring until the power output stabilizes.”

Knowing that initial degradation, Kedir said, is important because it could be anywhere from 0.6 percent or 0.8 percent to as high as 5 percent or 6 percent. “Then they stabilize and the modules will degrade at maybe half a percent every year or so.”

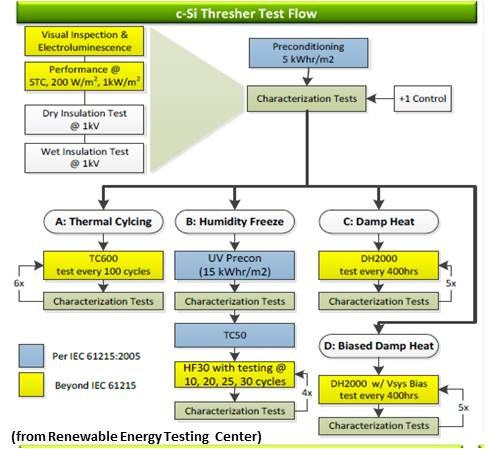

RETC’s reliability protocol is called Thresher Test Flow. It is a model for a formal reliability testing protocol being designed by an NREL-led task force of which Kedir is a member. Thresher Test Flow includes extended chamber tests for thermal cycling, humidity freeze, damp heat, and biased damp heat.

“The standard IE certification requires 1,000 hours of damp heat chamber exposure. That’s 85 percent humidity at 85 degrees C. It is supposed to simulate 25 years of operation. But in reality, what we are finding is that under operation some panels have shown unexpectedly higher degradations,” Kedir said.

RETC’s reliability tests use established IEC test procedures for performance and safety, with extended exposure times.

RETC has found that some products that pass at 1,000 hours often fail at 1,100 hours or 1,200 hours. “If you add just 10 percent more stress, they may fail dramatically,” Kedir said. “A lot of our customers are opting to go beyond the 1,000 hours to 1,500 hours, 2,000 hours; some go as high as 3,000 hours. Once the product fails, we help them figure out what failed. The manufacturers then go and improve their products in those areas.”

"We take a lot of the basic tests and we apply [the conditions for] two times or three times longer," Kedir said.

For damp heat, the module is tested at 85 degrees C and 85 percent humidity for 1,000 or more hours. “Then we do another test, the PID [potential induced degradation], which is very stringent," Kedir said. “It is the same test conditions, but with a system voltage bias added.” It is performed for between 100 hours and 2,000 hours.

“What a lot of developers and banks are saying,” Kedir explained, “is that the basic certifications are a manufacturer’s price of entry into the market. But it is not the gate of entry into purchase agreements. In order to be considered, the modules have to undergo additional tests. They have to prove they are better than the rest.”

With more rigorous testing, Kedir said, “we are finding issues with encapsulation, back sheets, and components such as junction boxes and connectors and cables. We are finding issues with diodes. A lot of things are showing up that before didn’t register when everybody was passing, but performance in the field was not up to par.”

Warranties and other protections make it possible for developers to recoup losses, Kedir said, but “they don’t want to wait until they see a shortfall in their production and go and seek remedies. They want to make sure they take care of it upfront, before they invest in these products.”

From comparative testing of “different products from different manufacturers tested at the same time,” Kedir said, “you can actually see whose product is better.” The results have impressed developers. “They said now they can’t sleep at night because they have some of those potentially bad modules in their developments.”

***

Interviews with Intertek and PV Evolution Labs are scheduled for future articles in this series.