SolarEdge, Tigo, and other power electronics companies’ devices optimize direct current (DC) produced by a solar module and, incorporated into what SolarEdge calls Smart Modules, feed power to a companion inverter designed to convert the optimized DC into alternating current (AC) for transmission.

SolarBridge, Enphase Energy (NASDAQ:ENPH), Enecsys and other power electronics companies’ microinverters put the entire power conversion system on each panel, making what SolarBridge calls an AC module, because it sends its own AC electricity into the transmission system.

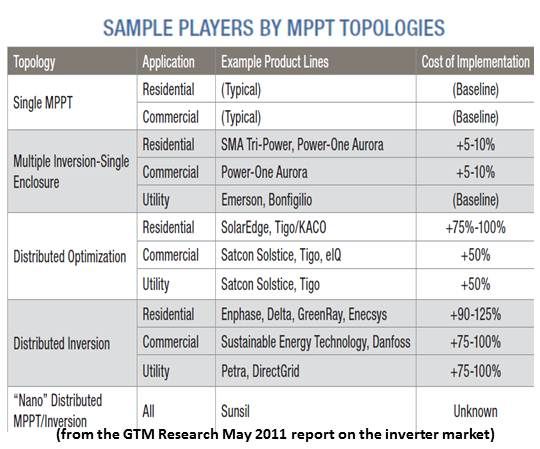

“The hardware components and software by which the system adjusts voltage to find the PV system’s maximum power point is known as the maximum power point tracker (MPPT),” GTM Research explained in its last report on the inverter market. “Traditional PV system topologies limit maximum power point tracking to the inverter level.”

Microinverters and embedded power optimizer topologies relocate the MPPT to the level of the module. That allows monitoring of individual modules for electrical safety issues, theft, shading, and soiling. It increases system performance but adds cost. “Cost and increased performance must be balanced,” GTM Research explained.

The DC optimizer approach beats microinverters on both cost and performance, SolarEdge North America General Manager John Berdner said. “It is extremely difficult to attach a microinverter to the laminate,” he explained. “You end up heating the cells.”

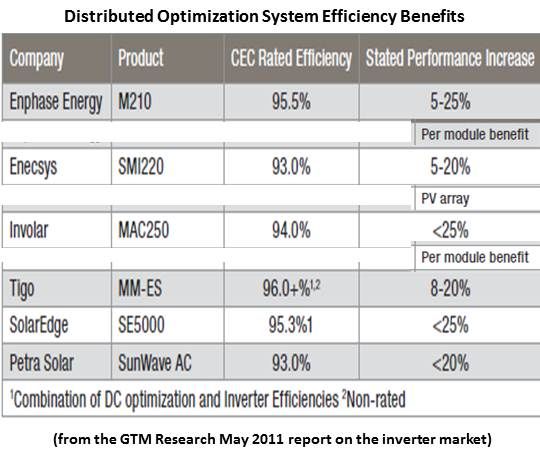

SolarEdge’s topology “is very high efficiency -- 98.7 percent average efficiency and 99.5 percent peak efficiency. Whatever is not efficiency is heat -- in our case, 1.3 percent average heat, and less than that under peak conditions. Microinverter solutions are in the range of 93 to 95.5, maybe 96, percent average efficiency best-case, so 4 percent of the module’s output needs to be dissipated as heat.”

Enphase PR Manager Kady Cooper rejected Berdner’s claim. “Enphase believes there is no technical reason to not have a frame-attached microinverter on a module.”

SolarBridge Marketing VP Craig Lawrence agreed. “It depends on how you mount it and how the inverter is designed,” he explained. “We mount with an air gap between our microinverter and the back sheet,” he said. “And we have designed the inverter so it directs heat away from the module.”

Lawrence said thermal chamber and rooftop data back his claim. “The impact of the microinverter on the temperature of the cells,” he said, “is not zero, but it is not a significant impact on the module’s performance.”

Losses in transmission to central inverters, Berdner said, are also “typically lower in a DC-based topology because the DC voltage is higher than the corresponding AC voltage.”

But, Lawrence pointed out, “a DC optimizer only does a part of the inverter’s function. It is not actually converting the DC to AC, which is where you lose all of your efficiency. The inefficiency still lives in the central inverter that you still need to have.”

Without a microinverter, Lawrence said, “you still have high-voltage DC on the roof. And you still have a single point of failure at the central inverter. With a microinverter, if you do have a module or inverter failure, it only impacts that particular module -- it doesn’t take down the whole system.”

For the best microinverters, Berdner said, “overall wiring and conversion losses are about a half percent to 1 percent less efficient than a DC optimizer with a separate inverter.”

On cost, Berdner acknowledged, microinverters beat SolarEdge’s topology in small systems. “When you get to 50 kilowatts, we are 35 percent lower cost. For large-scale systems, we are less than half the cost of a microinverter-based solution.”

“Our solution is geared toward distributed generation, not utility-scale,” Lawrence admitted. “Central inverters are so cheap, when you are at the one-megawatt scale, the benefits you get from the microinverter aren’t enough to make up for that cost differential.”

That was Berdner’s point. “If you buy one microinverter, the cost is X. If you buy 1,000, the cost is 1,000X. Fundamentally, the costs are linear.” With the SolarEdge topology, central inverters do more cost-effective service in larger systems. Also, “you eliminate the added cost for mounting an external device and you eliminate the cost of redundancies in the system like cables and connectors.”

Enphase Energy Commercial Product Manager Gene Choi disagreed. “If we compare on a strict inverter-to-inverter pricing scenario, this seems valid. However, if we look at the total cost of ownership of the PV system, microinverters come out on top for larger systems. We see installs in the hundreds of kilowatts because of the value microinverters bring to the total cost of ownership.”

“I think you will see DC optimizers getting used in very large systems,” Lawrence said, but “costs of microinverters are dropping, and the power rating is going up. Right now you do get a scale cost advantage on very large systems. Microinverters have only been around for about three years and they now account for over 30 percent of all U.S. residential installations. It is a better solution for residential rooftop systems.”

Leading inverter makers and traditional PV system topologies continue to dominate the marketplace, according to GTM Research, because established companies like SMA and Power-One (ETR:S92) (NASDAQ:PWER) are seen as more bankable due to their reliability records and existing distribution channels.