The fiercely competitive commercial-scale rooftop solar marketplace is driving innovations in racking systems.

One major breakthrough is ballasted mounting, which installers are increasingly turning to as permitting authorities recognize its safety. Ballasted racking allows systems to be situated on flat or nearly flat roofs with minimal attachments, cutting the time and complexity -- and therefore the cost -- of installation.

Price pressure is also driving the growth of module-and-rack integrated systems, which arrive at the installation site assembled and ready to be lifted to the roof and wired. SunPower (NASDAQ:SPWR) and SOLON Corp. are among the companies leading the integrated-system charge.

SunPower’s T5 and T10 Solar Roof Tiles are built from the company’s proprietary modules and racks. Using the T5 tiles, SunPower can install up to ten modules per man-hour.

The rack for SOLON Corp’s SOLquick system is designed to be integrated with whatever unframed solar laminate the company finds to be cost-effective and of adequate quality. “We can use SOLON laminates, but we have the flexibility to use any laminate we internally qualify,” SOLON R&D Director Bill Richardson told GTM.

SOLON promises installation at the rate of fifteen modules and 4,200 watts per man-hour. Each SunPower module is about 320 watts, meaning an installation rate of 3,200 watts per man-hour. But the SOLON laminates promise no more than a 15 percent efficiency, whereas the SunPower modules get over 20 percent, though at a higher cost for the higher productivity.

SunLink, which has installed about 300 megawatts on some 1,500 roofs with its non-integrated racking since 2004, responded to the current cost-cutting drive by building a better non-integrated product.

Two years ago, SunLink’s crews were installing at a rate of approximately six modules per man-hour. With the innovations SunLink has built into its new Precision RMS racking system, crews can now install at up to eight modules per man-hour. With its Core RMS system, they can get up to nine modules installed per man-hour.

The increased installation speeds keep SunLink competitive with integrated system installers, particularly because the modules used are likely to be less expensive than SunPower’s, but more efficient than SOLON’s, at a competitive cost.

“Increased competition and price pressure have forced us to look at everything in our product line,” SunLink Products and Strategy VP Yury Reznikov said. “We chose a dual-product approach.”

The Precision product was designed for the harshest environments, and the Core product is suitable for approximately 80 percent of all solar rooftop situations, he explained.

Precision RMS installs faster for a number of reasons. First, its foot placement can be adjusted to the roof’s structure. In addition, the system has a significantly reduced number of parts, many pre-assembled, which reduce the installation time. Also, a rubber interface designed for the space between the aluminum and the roof eliminates the need for slip sheets. Finally, the entire racking system has a safety certification that eliminates the need for running copper grounding wire.

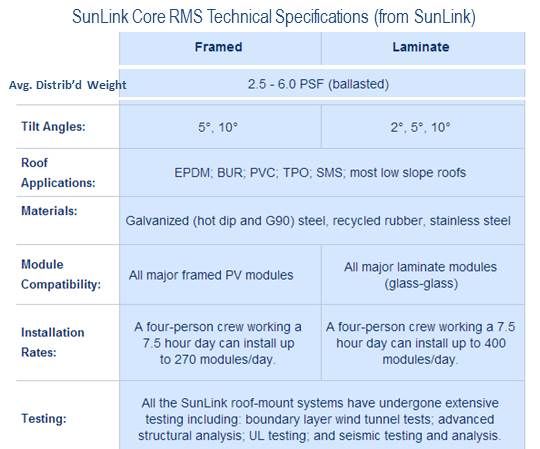

Core RMS is “very basic,” Reznikov emphasized. “It costs probably 20 percent less.” The reduced price and speed of installation come from fewer components; the use of steel instead of more expensive aluminum; a fixed five- or ten-degree tilt; a simple top-clamp assembly; and its fixed feet.

Reznikov plans continued incremental improvements, “on about a twelve-month cycle. We’re already working on the next generation of Core.”

The consolidation of parts is of particular importance. “If we can minimize or standardize on components, it can significantly help in cost,” he said.

There are advantages to an integrated system, Reznikov acknowledged. But there are also disadvantages. Shipping can be more costly because integrated systems cannot be packed tightly. SOLquick, Reznikov said, ships four modules to a palette. “Those shipping costs have to be high. And we’ve actually lost deals because of shipping costs. We think very hard about how components stack and where suppliers are located.”

Time can also be lost while craning palettes to a rooftop. Craning five palettes might get an average SunLink installation onto a rooftop, Reznikov said, whereas an integrated system of the same capacity might require craning twenty palettes.

But the biggest thing, Reznikov said, is choice. Non-integrated systems are “module-agnostic.” That “allows a customer to find the module supplier they feel comfortable with from the cost, bankability and quality perspectives, and the mounting system supplier that fits their needs.”

Traditional racking manufacturer Renusol America’s CEO Bart Leusink told GTM virtually the same thing. “Our Renusol CS60 is compatible with almost all 60-cell and some 72-cell modules currently in the markets, which allows for a broader adoption, without limiting the user or installer.”

“Giving customers the option to pick out the best module and the best racking,” Reznikov said, “outweighs any small installation time differential with an integrated system.”