We're in the midst of the great lighting transformation, with solid-state LEDs on the cusp of transforming the lighting industry. The Edison bulb will soon be a relic and CFLs an interim step.

The industrial lighting industry is worth $5 billion in the U.S. alone and Digital Lumens, a light-emitting diode (LED) lighting and control startup just announced a big design-win in what is one of the opening salvos of the industrial LED lighting revolution.

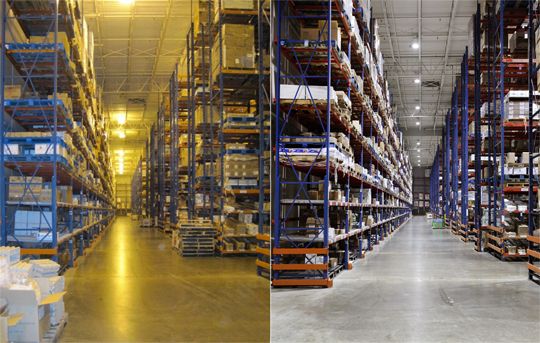

Digital Lumens' customer, Maines Paper & Food Service, deployed the company’s Intelligent Lighting System in their 9-football-field-sized, 460,000-square-foot headquarters in Conklin, New York. Here are the expected results:

- Lighting-related energy use reduced by 87 percent.

- Saving 1,726,108 kWh per year (enough electricity to power 200 homes for a year).

- A reduction of 1,240 metric tons of CO2 per year.

- Improved light levels and safety facility-wide.

Maines is one of the country’s largest independent foodservice distributors, with revenues approaching $3 billion and facilities serving 33 states. This facility could be the first of many Maines warehouses going the LED route.

Working with their energy efficiency partner, Groom Energy Solutions, Maines saw lighting as an opportunity for savings and conducted an evaluation of the alternatives, including fluorescents and LEDs. Maines selected the Digital Lumens system, which combines LED-based fixtures, ZigBee-based mesh networking, and software, as a one-for-one retrofit of high bay warehouse lights, and The New York State Energy Research and Development Authority (NYSERDA) provided the project incentive.

Lighting represents about 20 percent of Maines' warehouse electricity costs. On average, lighting consumes 25 percent of the energy in commercial buildings and 12 percent in homes, according to the DOE's Buildings Energy Data Book for 2008. Seven percent of all the energy consumed in America is used to light our homes and businesses. Here's a link to a DOE report on the potential of energy savings with solid state lighting (SSL).

Digital Lumens is using the directionality and controllability of LEDs to save big money for industrial lighting applications. The Boston-based firm has raised over $11 million from Boston-based VCs Black Coral Capital, Flybridge Capital Partners and Stata Venture Partners, with a staff that includes members of recent SSL success and Philips acquisition, Color Kinetics.

Maines can track energy usage and occupancy on a fixture-by-fixture basis, enabling them to tune the light program to maximize efficiency. The system also creates a lighting network inside the facility, which creates opportunities for future capabilities and/or measuring and monitoring other aspects of the facility.

I spoke with the CEO, Tom Pincince, and he said, "We deliver 100 percent or more light for 10 percent of the energy." Pincince said that their intelligent lighting systems can achieve "radical new levels of efficiency" and that for the first time, "customers can have real control of their lighting" to achieve that 90 percent reduction in energy.

It's not a new idea. Variants on lighting networks have already been introduced by Lumenergi, Adura Technologies, HID Labs, Juice Technology and Redwood Systems. But it's still an emerging sector -- only around 1 percent of lights in California commercial buildings are networked. Albeo Technologies also makes high bay lighting, but minus the networking piece.

According to Digital Lumens, lighting typically costs $1 per square foot per year, and they can reduce that to ten cents with the extra element of control and intelligence. There is room for on-board sensors, on-board computing and the ability to assimilate knowledge of human behaviors and occupancy levels.

The startup gets to market through energy-aware lighting retrofit specialists. With its emphasis on LEDs, Digital Lumens will likely concentrate on new construction and "heavy" retrofits. HID Labs, Lumerengi and Adura all focus on traditional lights and are moving into LEDs -- their solution can swap straight into existing buildings and light fixtures. Redwood and Juice are LED-only, but provide novel functionality because they get rid of wires and connect lights through low-voltage computer cable. Digital Lumens offers a solution from fixture to controls to software.

Although the Digital Lumens system is twice as expensive out of the box as a fluorescent, it's twice as efficient and the energy savings result in a two-year payback. High upfront cost is an immense barrier in residential applications but if the payback is less than two years, industrial lighting customers seem willing to pay, according to the CEO.

In a particular case study, Digital Lumens dropped a customer's cold storage facility lighting bill 95 percent, from $225,000 to $10,000. The site was 268,000 square feet, and is used 24 hours a day, 7 days a week, 365 days a year with a 10 percent occupancy.

Digital Lumens' carefully designed fixture channels light in a highly precise fashion. The CEO said, "It's all about footcandles going exactly where they're needed" by "punching light into an aisle when and where it's needed."

Other VC-funded startups going after the solid-state lighting illumination market include bulb-makers Bridgelux, Lemnis , Luminus, and Luxim. Intematix makes phosphors for LEDs and Nuventix builds active cooling technology for LED lighting.

Rob Day of Black Coral Capital, an investor in the firm, is enthusiastic about Digital Lumens. He raved about his portfolio firm in an email to me back in June:

"We hear a lot about LEDs being the wave of the future, but it's tough to find cost-effective LED fixtures today -- it's all about promises for the future. Digital Lumens is accomplishing 90 percent energy savings today, with customer payback periods that are no-brainers. Not projected savings -- actual proven savings. They've taken a systems-based perspective, using not only the LED chips but more importantly, intelligence in the fixture that allows them to use today's chips to accomplish tomorrow's economics."

Day continued, "chip-level improvements are important and valuable. But as an investor, rather than looking for manufacturers of the (temporarily) brightest chips, I'd been looking for the Dell of LED lighting. Combining the right components into a cost-effective and compelling family of fixtures. At the end of the day, customers don't care about the technology their lights are based on. They care about getting the right amount and highest quality of light where they need it, at the lowest cost. And that's the genius of the team at Digital Lumens."

According to CEO Pincince, "The industrial world is quickly going to LEDs -- the laggards and are going to be residential and class A buildings. The industrial lighting market is big with big facilities and with a big impact. In Maines case and in many high-bay applications, the incumbent technology is high-pressure sodium.

Pincince said that the enormous reduction in energy at the massive Maines site which is occupied 24/7 actually moves the needle on energy usage for the entire town of Conklin, in which it's situated.

The CEO finished with "This is no compromise, energy-efficient lighting with improved lighting quality from what the customer previously had."

Before and after the Digital Lumens lighting experience....

***

Michael Kanellos contributed to this story.