California will soon require arc fault detectors in solar installations, which will help reduce the risk of fire.

In a recent New Jersey warehouse fire, it was found that a rooftop solar array did not cause the fire, but did play a role in hampering firefighting efforts. John Kluza, Solar Strategic Marketing Manager at Sensata Technologies, characterized the case as “unfortunate, but a good opportunity for electrical protection units to get a higher profile."

Research indicates that rooftop solar-caused fires are very rare. A German study found approximately 75 instances out of some 1.3 million installations, while a U.S study found only seven instances in the entire country.

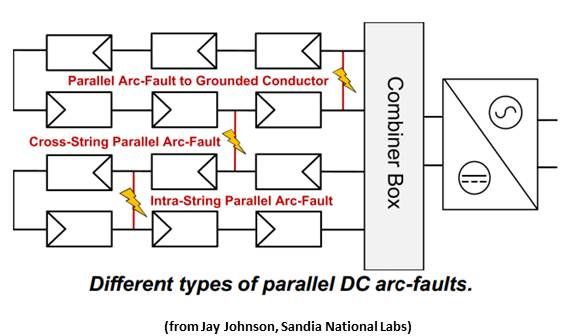

Arc faults are caused by air gaps between electrical conductors. The most common causes are faulty manufacturing, installer error, or aging, degraded connectors, Kluza said. Electrical current across the loose connection produces sparks that could cause a fire.

An arc fault current interrupter (AFCI) senses the DC current coming into inverters in smaller arrays or into combiner boxes in commercial and utility-scale systems. The increased electrical noise of an arc fault, Kluza said, will trigger a system shutdown before it causes a fire.

The 2011 National Electrical Code (NEC) requires AFCIs in rooftop solar arrays, Kluza explained, but states are allowed to implement NEC requirements at their own pace.

“Arc fault is a serious issue, but historically, it has not been a market-driving issue,” explained GTM Research Senior Analyst MJ Shiao.

An AFCI device could add anywhere from $25 to $100 in cost to each string inverter in a solar installation, according to Kluza. As the biggest U.S. solar market by far, California’s enforcement of NEC mandates for residential and commercial-scale installations is expected to spur growth in a market that has so far remained reluctant to add any additional cost to solar.

Some SMA inverters already include “the first arc-fault detection devices listed to series arc-fault protection standard UL 1699B,” according to a presentation recently made by Jay Johnson of Sandia National Labs.

Tigo Energy, Sensata Technologies, Santon Holland, Eaton Corporation, and E-T-A Circuit Breakers also have UL certifications for their products, Kluza noted. MidNite Solar and SolarBOS use AFCI technology, Johnson added, and SolarEdge power optimizers have module-level AFCI capability.

“Code revisions at one point looked like they could require module-level devices,” Shiao pointed out.

Module-level devices would be one of the most complete solutions to the broad set of concerns firefighters have with rooftop solar because they would potentially eliminate current from wiring even if sunlight was still hitting the modules. But module-level power electronics remain little used by the industry due to their costs and limited performance record.

A key differentiator between the emerging AFCI products from an operating cost perspective, Kluza said, is having “a robust nuisance-tripping avoidance capability.” Some AFCI technology too readily trips off solar systems in response to building electrical activity that is not in fact an arc fault. Reactivating those systems could be costly enough to compromise solar economics, he explained. "Sensata Technologies," Kluza added, "has spent a lot of time working on [the problem of] nuisance-tripping.”

“The best arc fault is one that never happens,” Johnson’s presentation noted in describing the importance of AFCIs. When devices can identify “precursor signals” before a tripping mechanism is needed, “PV systems can be monitored for signs of future arc-fault failures and prognostic maintenance could be prescribed.”