In a competitive, fast-moving market, how does a technology firm determine which materials and processes are needed to make the best possible device? How does a solar or battery or LED company, betting its future on a particular material, plan an experimental direction and investment program in research and development?

The traditional route was to depend on the instincts of smart people and grind away with beakers and spreadsheets.

Intermolecular (Nasdaq:IMI) has a different approach to experimentation. Intermolecular uses a combinatorial experiment technology and acts as an R&D accelerator for its customers. Through paid collaborative development programs, the company develops technology and IP in advanced materials, processes, and integration.

In turn, Intermolecular gets a royalty from products sold that were developed with its technology.

Intermolecular had 2012 revenue of $66.8 million, up 24 percent from $53.8 million in 2011. Net loss for 2012 was $0.8 million.

Intermolecular has been public since 2011 and moving more into renewables and energy. We visited the firm last week at its San Jose headquarters.

We spoke with SVP Sandeep Nijhawan, leader of the firm's energy and display efforts. (Nijhawan was also part of LED startup Siorah, acquired by IMI.)

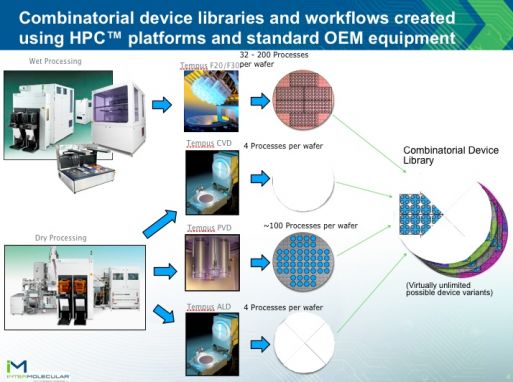

Intermolecular's value is its ability to do many miniaturized and site-isolated experiments on a single wafer -- up to 72 experiments per cycle. As an example, a wafer can be run with eighteen different silicon wafer texturing processes, each with four different passivation techniques. Intermolecular has worked on developing a more durable, lower-cost antireflective coating for PV glass, as well as investigated the complex CIGS absorber material.

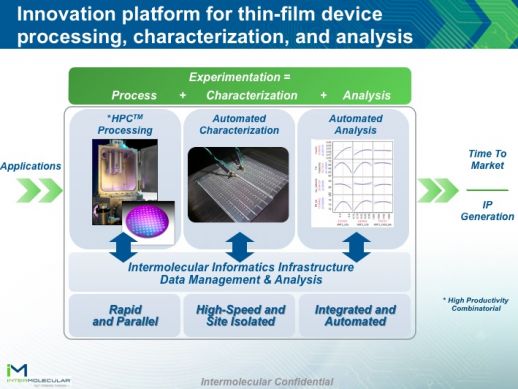

In a project that would take another company months to complete and likely tax its analytical capabilities, Intermolecular can have a throughput of hundreds of uniquely characterized solar cells per week. It has the flexibility to change gases, targets, gradients, chemistries and integration schemes. This is combined with automated probing and an "Informatics" software system.

As we've reported, solar thin film leader First Solar (FSLR) announced a partnership with Intermolecular last year and just announced a two-year collaboration and licensing agreement aimed at increases in photovoltaic conversion efficiency. "The combinatorial approach to material and process screening has shown promise to augment First Solar's already world-leading research and development capabilities in CdTe solar technology," said Raffi Garabedian, First Solar's CTO, adding, "The device we make is a semiconductor junction and very similar to a CMOS device -- and you can imagine that Intermolecular's process expertise could be turned to PV."

Craig Hunter, Sr. VP of Global Sales and Marketing, said, "What we exist to do here is accelerate learning curves. Look at the headroom on the CdTe device -- there is tremendous opportunity to improve."

Longer-term ambitions for Intermolecular include thin-film batteries, super-capacitors, and electrochromics. The company is working with advanced glass coatings for window glass with Guardian, has a collaboration with Epistar on LED materials, and a collaboration with King Abdullah University of Science and Technology (KAUST).

Intermolecular's experimental platform allows companies working in complex materials systems to confront integration challenges, new materials, new processes, reliability issues and material interaction in a rapid and direct fashion.

If the massive experiment yields a process that goes to commercial production, both Intermolecular and its client profit.