The question remains: can organic solar cell technology be successfully commercialized in an unforgiving solar market dominated by cheap crystalline silicon and First Solar?

Heliatek of Dresden, Germany thinks so. And so do its investors.

Heliatek just closed its $22.5 million series C funding round, led by AQTON SE, along with European VC investors Bosch, BASF, Innogy Venture Capital, Wellington Partners, eCAPITAL, HTGF and TGFS. AQTON SE is a strategic investment holding wholly owned by Stefan Quandt, a billionaire investor with an unusual past.

Heliatek has raised more than $50 million since its founding in 2006. Up until now, the markets that the company has targeted, including building and construction materials companies and automotive suppliers, have proven unfruitful for photovoltaics. It is hoping to achieve production of "transparent" thin-film solar by the middle of next year.

The company holds the world record of 12 percent cell efficiency for opaque organic solar cells.

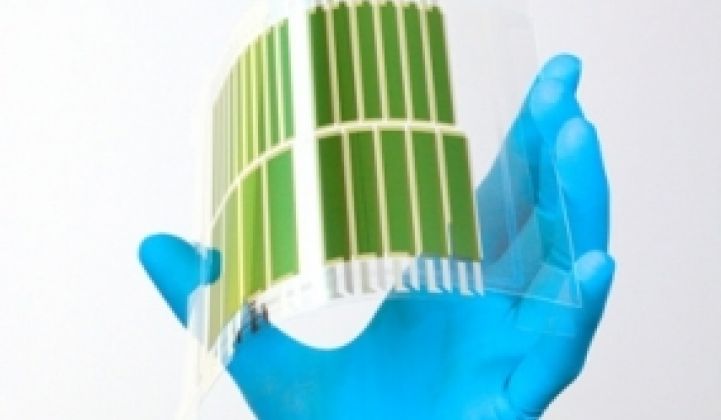

Organic solar cells (OSCs) are sometimes referred to as third-generation solar technology, coming after crystalline silicon and thin-film solar technology. OSCs can be divided into two categories: polymer-based (large molecules) and oligomer-based (small molecules). OSCs are lightweight, nontoxic, and semi-transparent. They hold the promise of low-cost manufacturing, but their efficiencies tend to be very low -- until now, at least -- and their long-term reliability has been called into question. Currently, global capacity of OSCs amounts to just a few megawatts.

Heliatek uses vacuum deposition of very homogenous layers of small-molecule oligomers at low temperatures. The process doesn't use solvents (as printing-based processes do), and that serves to separate the firm "from the other guys," according to Heliatek's CEO, Thibaud Le Séguillon. When we last spoke to him, Le Séguillon suggested that the firm's technology can be thought of as an organic light-emitting diode (OLED) in reverse. Heliatek itself is developing the organic materials it uses, and the firm claims to use just 1 gram of organic material per square meter in its roll-to-roll process.

Back in late 2009, Heliatek raised $27 million to build its first factory from VC investors Wellington Partners, RWE Innogy Ventures, and BASF Venture Capital, as well as industrial giant Bosch. The firm was founded in 2006 as a spinoff of the Universities of Dresden and Ulm.

Organic solar cell competitors

Other organic and dye-sensitized solar cell (DSSC) developers and aspirants include Konarka (bankrupt), Dyesol, Solarmer, Plextronics (bankrupt and sold to Solvay), EPFL, Mitsubishi, Peccell, and G24i. Dyesol, which is publicly traded, builds equipment to manufacture DSSCs; however, the firm's chief product offering to date appears to be press releases.

Eight19 Limited raised $7 million from the Carbon Trust and Rhodia to develop plastic organic solar cells (presumably, the "Eight19" refers to either the time it takes sunlight to reach the earth or the technology's price per watt). Ireland's SolarPrint has eliminated the liquid part of the DSSC process, replacing it with nanomaterials and printing. This means that all of the active elements of SolarPrint's cells are applied through printing. Even Intel has done some research into OSCs.

Heliatek is focused on the promised-land market of building-integrated photovoltaics (BIPV). This includes windows and facades, as well as concrete and other building materials. When it comes to BIPV, this author has the same opinion that Gandhi had of Western civilization: I think it would be a good idea. There is no real BIPV market today, in the true sense of BIPV (see "The Realities of Building-Integrated PV").

Performance records are occurring across the board in every photovoltaic materials system, from CdTe (First Solar) to CIGS (MiaSolé) to CIS (Solar Frontier) to GaAs (Alta Devices) to triple-junction CPV cells (Solar Junction) to crystalline silicon (SunPower).

Heliatek continues to set records in the organic solar cell field. But the difficult task of commercializing economical and reliable organic solar cells remains.