Carnot Compression, an early-stage startup, has resurrected a century-old technology to demonstrate that isothermal compression is achievable and can save energy wherever compressors are used -- which is pretty much everywhere.

The core technology of the eight-employee startup's invention is based on the Taylor compressor.

The Taylor compressor

In the late 1800s and early 1900s, Charles Taylor (1859-1953), a self-taught engineer and geologist, designed and built a series of awesome power and hydraulic engineering projects in Canada and the U.S.

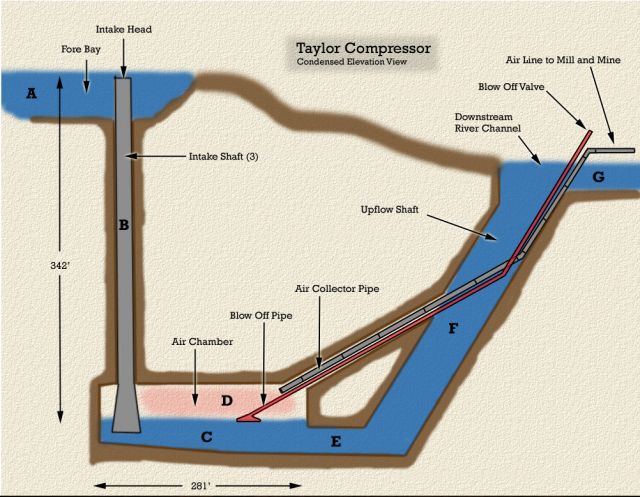

His hydraulic-air-compression-power systems used the same phenomenon exploited by the iron-age trompe; Taylor harnessed the power of gravity and the weight of falling water to create a compressed air resource that powered remote mining operations and factories. His power plant at the Ragged Chutes mine on the Montreal River near Cobalt, Ontario ran at 82 percent efficiency for decades with little maintenance. The Taylor compressor provided isothermal compression and delivered compressed air at 40,000 cubic-feet per minute (cfm) at 120 pounds per square inch (psi) -- equivalent to more than 5,500 horsepower.

But the technology was largely forgotten until resurrected by Carnot Compression on a much smaller and less-geographically-constrained scale.

(Taylor's projects and brilliant life are detailed here. A schematic of the compressor and photos of the invention can be found at the end of this article.)

Carnot Compression goes isothermal

Carnot Compression's technology is based on the operational concept behind the Taylor compressor. According to the startup, the Taylor compressor was the only isothermal compression system in operation until Carnot Compression's invention.

The startup's technology achieves the necessary speed and force to compress air not with falling water, but with centrifugal force. A mixture of gas and liquid is combined in an emulsion, while a rotating compressor uses centrifugal force "to shrink the bubbles, compressing the gas inside them as they move from the center of rotation to the outside of the compressor casing. The bubbles collapse as they join together in a pressure chamber."

Todd Thompson, the CEO of the new startup, told GTM yesterday, "We've taken the Taylor compressor and we are literally spinning it around an axle, replacing gravity with centrifugal force."

According to the firm, "This single-stage compression cycle not only compresses the gas up to 200 times the entry pressure while maintaining the entry temperature (isothermal), but it also dries the gas to levels beyond most industry requirements."

The company suggests that "the liquid in [the] system acts as a giant heat sink, just as in Taylor’s system, absorbing the heat of compression." The company asserts that capturing the heat energy of compression within its process "generates much higher efficiencies than traditional adiabatic compression methods, with estimated energy savings of 25 percent to 50 percent for typical applications."

The CEO emphasized, "We're not violating laws of physics. There's still heat of compression -- the liquid absorbs [that]."

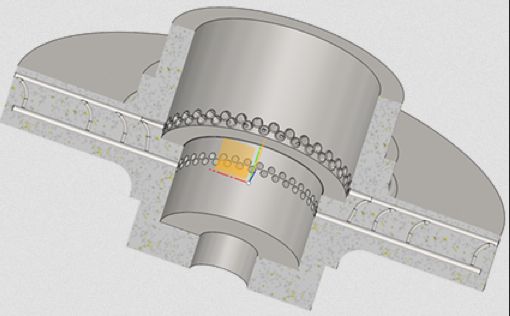

Drawing of Carnot Compression's impeller, from company website

Ubiquitous compressors

Compressors are used in industrial air compression, numerous oil and gas compression applications, CNG fueling, refrigeration and HVAC applications.

Carnot Compression rattles off some relevant statistics:

- 10 percent of U.S. industrial electricity goes to power compressors.

- 5 percent of U.S. natural gas production is consumed by natural gas compression.

- Air and gas compression consumes at least $24 billion of energy costs in the U.S. and EU

- Energy costs account for roughly 75 percent of a typical compressors’ lifetime cost of ownership

The CEO cited typical uses such as pneumatic tools and oil and gas applications, but said, "We're going after plain-vanilla compressed air. Compressed air systems are ubiquitous to any manufacturing process. Any production line is going to have compressed air systems, sometimes running 24/7."

Getting from lab to market

The CEO told GTM, "Right now, we have multiple working benchtop prototypes proving the concept," adding, "We're working on a larger-scale 100 cfm prototype." Thompson said, "If you look at a comparable compressor, it would require a 25-horsepower motor as the prime mover. We think we can get that down to 17 horsepower to generate an equivalent amount of compressed energy."

But how does a startup funded by founders and family move a new technology forward and compete with corporate giants such as Ingersoll Rand, GE, Hitachi and Emerson?

The company is looking for strategic investors and partnerships, as well as early-adopter customers to get to commercialization. The CEO has also mentioned the possibility of licensing. Early-stage energy-focused investors, admittedly a very small group, might be interested in this kind of thing, though industrial strategics would likely make for a more receptive audience.

But first, Carnot has to prove its technology really has the potential to be more efficient than today's compressors, a mature technology, for sure, but one that's not without ongoing innovation.

"We do not have efficiency test data on our benchtop units; that is one of our key objectives in completing the 100 cfm prototype," said the CEO.

The columnar Taylor compressor has a relatively simple flow regime compared to a centrifugal machine -- where the physics of complex flows, bubbles and viscosity could provide careers for scores of PhDs. There are still a lot of technical risks ahead for Carnot.

The CEO told GTM, "It's amazing to us that [this technology] hasn't been tried and it hasn't been taught. People didn't believe that isothermal compression was possible." He said the firm's invention has only one moving part and is a feat of genius on the part of founder and Chief Science Officer Mark Cherry.

"We've proven we can compress air isothermally -- now we have to engineer and design commercial products. From our perspective, we've already done what people said can't be done."

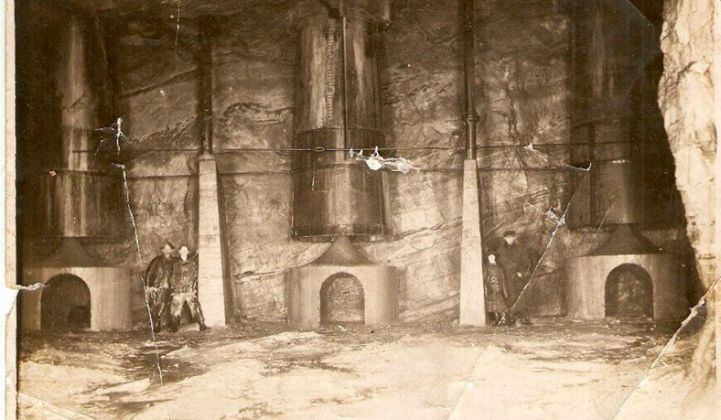

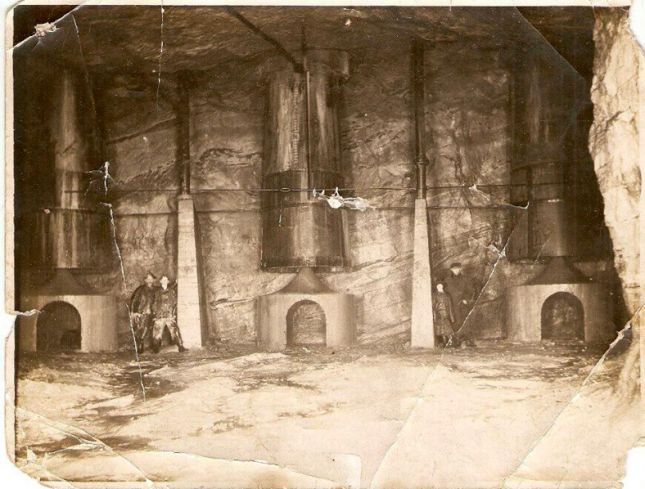

A 1906 photo of the cavern below the intake heads of the Taylor Hydraulic Air Compressor at the Victoria Copper Mining Company on the Ontonagon River. The compressor powered most of the mining equipment, including a small-grade compressed-air rail engine for the mine’s short line railroad. (Photos by Charles Taylor (?), originally published in the Engineering & Mining Journal in 1907.)

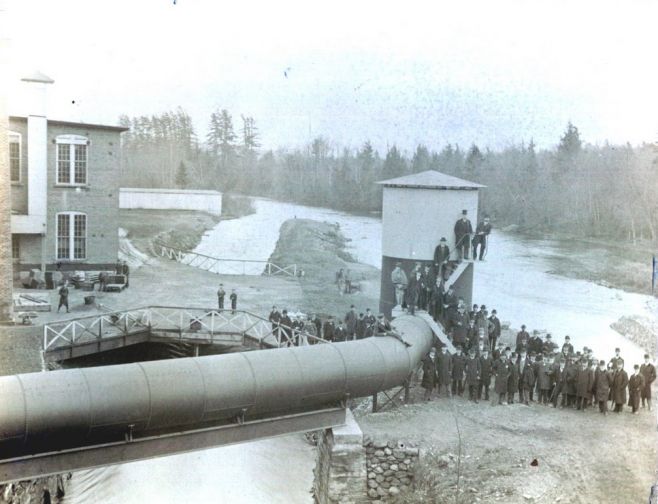

A view of some of the above-ground portion of the hydraulic compressor at Victoria

A view of the underground air chamber and blow-off pipe

A schematic of the Victoria hydraulic compressor (not drawn to scale)