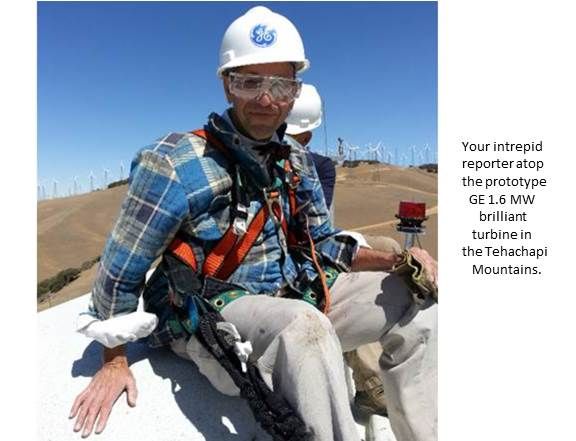

With the launch of the first three GE brilliant wind turbines approaching, the world’s leading turbine manufacturer invited media to its test center to see its machine in operation and take a look at the inner workings.

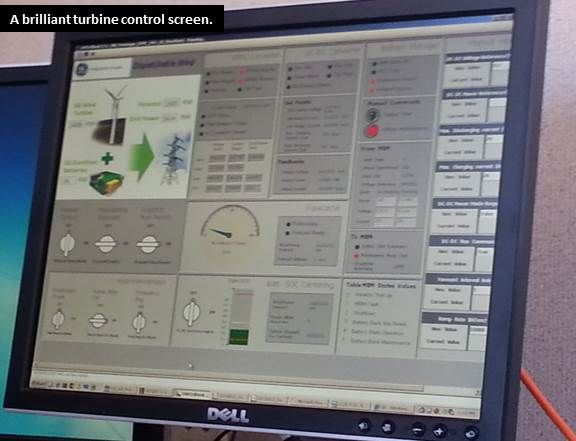

GE's (NYSE:GE) engineering continues to move competitively toward the same two broad objectives as leading international manufacturers like Vestas and Siemens: Achieving a better automated response by the turbine’s multiple onboard computer systems to data from its network of sensors, and allowing remote operations centers to wirelessly control variables the automated systems can’t manage, like wind changes, grid conditions and lightning strikes.

Three of GE’s 2.5-megawatt, 80-meter-tall brilliant turbines with 120-meter rotors will be installed by Invenergy at a Texas wind project by the end of this year. The new height, rotor length and data analytics will allow the turbine to achieve a 52 percent capacity factor in moderate, Class 3 winds of speeds of 7.5 meters per second, according to GE Wind Product General Manager Keith Longtin.

The brilliant turbine will also integrate 50 kilowatt-hours of battery storage, situated in a cabinet on a nearby ground pad, into the turbine’s intelligent operating system. Although a single turbine’s storage may not be a marketable quantity of electricity, Longtin acknowledged, a project’s combined storage could provide any one of three valuable functions, which GE calls “apps.”

The Invenergy turbines’ storage will be used for the first of the apps, labeled "predictable power" by GE. Stored, dispatchable electricity, Longtin explained, increases a wind project’s capability to meet contractual obligations. That makes it more competitive with other generation sources.

Second, stored electricity can be sold into grid operators’ frequency regulation markets to smooth the variations that can disrupt service.

Third, batteries give wind projects the ramp control they need to feed power into the grid at the required 10 megawatts per minute. Wind-generated electricity can then be stored when the wind is blowing but there is no demand for power, and then sold when the energy market is buying.

Each app, Longtin said, provides wind project operators with a potential new revenue stream. Together, he added, GE’s proprietary calculations show they can cut the cost of integrating wind into the grid by as much as 30 percent.

The estimated cost of integrating wind and other renewables into the transmission system is $1 to $7 per megawatt-hour, Longtin said, citing widely accepted numbers. “That translates to at least $400,000 to $500,000 annually for a 100-megawatt wind project. We believe we can do better than that.”

One key to savings, Longtin said, is the turbine-based battery storage. Integrating storage into the turbine’s existing converter and power electronics eliminates extraneous costs of inverters and other power conditioning hardware associated with large-scale add-on storage.

Also key is the brilliant turbine’s ability to assimilate and use data, especially GE’s proprietary five-minute to fifteen-minute weather condition forecasts, which, Longtin said, have advantages to forecasts supplied by industry leaders like AWS Truewind and 3Tier.

The batteries for the prototype brilliant turbine at the Tehachapi, California test center are GE Durathon sodium nickel chloride batteries. But the company is “battery-agnostic,” Longtin insisted.

Different applications require different types and amounts of storage, he explained. Frequency regulation requires a quicker responding “power” battery. Ramp control can be done with an “energy” battery with more storage capability. The point, Longtin said, “is that we have a customizable solution.”

“We are linking big data with big machines,” GE Renewable Energy VP Anne McEntee recently told GTM. “We collect 400 data points in a turbine. That is tens of thousands of data points in a wind farm.”