A Japanese university announced that the performance of the materials used in lithium-ion (Li-ion) rechargeable batteries can be drastically improved by using an ultracentrifugal processing technology to add an active material inside carbon.

The graduate school of the Tokyo University of Agriculture and Technology announced electrode materials made by adding lithium iron phosphate (positive-electrode material, LiFePO4) and tin oxide (negative-electrode material, SnO2), respectively, inside carbon.

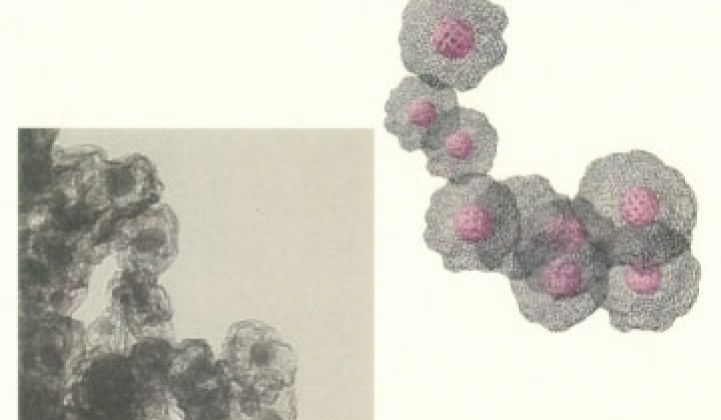

As for LiFePO4, the university achieved a specific capacity of 131mAh/g in a discharge of 60C (one minute). In regard to SnO2, it ensured a discharge of 10C (six minutes) and a charge/discharge cycle life of 800 or more, the university said. Specifically, the university made two positive-electrode materials. One is the "ground cherry type," in which LiFePO4 is included in hollow carbon. The other is the "podded pea type," in which LiFePO4 is included in carbon nanofibers (CNFs).

For more on the story, please go to TechOn.