There’s a supply-demand imbalance overtaking the world’s electricity grids, driven by renewable energy resources that shift unpredictably with the weather and reach maximum output when power isn’t needed. Today’s natural gas peaker plants, which ramp up and down to balance that ever-changing supply, are an expensive and environmentally unfriendly way to manage that imbalance.

Another option is virtual power plants -- smart grid technologies that can reach into customer homes and businesses to tweak and shape power demand to match the ups and downs of green power supplies. But getting thousands of devices to respond fast enough and with enough coordination to do the trick is a major challenge, one of many facing utilities, renewable power generators, and technology-enabled customers on the grid edge.

Over the past four years, an innovative project spanning Canada’s three Maritime Provinces of New Brunswick, Nova Scotia and Prince Edward Island has been working on just that task. It’s called PowerShift Atlantic, and it's controlling a combined 11.5 megawatts (of the project’s target of 26 megawatts) of connected loads that range from big industrial HVAC systems and water pumping stations, to thousands of remote-controllable water heaters in customers’ homes.

Unlike typical demand response systems, these loads aren't just able to power down to reduce grid stress. They’re also able to absorb excess grid power, a critical feature to avoid the need to curtail generation from the provinces' combined 675 megawatts of on-shore and offshore wind power -- figures that are likely to grow as each province strives to meet goals of 40 percent renewable energy by 2020.

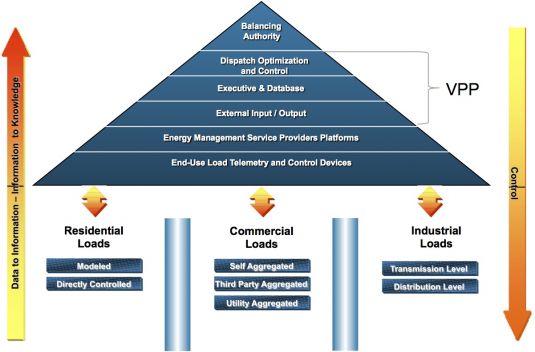

Also, instead of asking lots of customer loads to turn down in a scattershot, all-or-nothing manner, PowerShift Atlantic has built a tiered structure, with individual customer equipment aggregated under five individual "Demand Management Service Providers” that monitor and control them on a regional basis. These, in turn, connect to a centralized virtual power plant (or “aggregator of aggregators”) system that serves as a grid operator interpreter and coordinator to each of the five groups, serving up minute-by-minute instructions while making sure to prepare for longer-term needs.

Leidos, the company formed by the spinout of SAIC’s non-government contracting business units earlier this year, is in charge of this master control function, which it has dubbed Integrated Load Management. In simple terms, PowerShift Atlantic is trying to create an integrated solution to a problem being tackled by virtual power plant and grid-responsive demand management projects in Europe, North America and Asia, all of which are trying to combine renewable energy and flexible loads.

“You can’t dispatch renewable generation -- you get what you get when you get it,” Steve Winstead, senior systems architect with Leidos, said in an interview last week. “What can we do to offset that?” The answer is simple in terms of the concepts involved -- but devilishly complex in the execution. Here’s how it works.

The Distributed, Hierarchically Managed Grid-Balancing System

Let’s start with the core building blocks of PowerShift Atlantic’s project: the individual loads that make up its power-shifting and -shaping resources.

These include lots of thermal loads, like water heaters, refrigerators and building HVAC systems, that have some wiggle room as to how hot or cold they need to be and how long they can be left without power to drift slowly outside of optimal temperature settings throughout the day. They also include water-pumping systems, which can pick and choose when in the day they move water, as long as they get it done within a certain timeframe.

PowerShift Atlantic has enlisted residential and commercial heating systems manufacturer Dimplex, electric thermal storage system maker Steffes and Atlanta-based home-to-utility load management technology startup Sequentric in its efforts, as well as two startups with expertise in managing these kinds of loads to serve as its demand management service providers (DMSPs).

One of them is Integral Analytics, which has software for predicting and managing distributed home and business loads to match grid needs, and is working on projects on Prince Edward Island and for the University of New Brunswick. Another is Enbala Networks, which has technology to turn water pumps and energy storage resources into fast-reacting grid response systems, and is working with New Brunswick and Nova Scotia’s utilities.

In all cases, “we wanted our solution to be totally invisible, not just transparent, but [as if] you don’t even know it’s going on when it’s going on,” Winstead said. “We recognized right upfront that even though these loads had flexibility, we could exhaust them. We could start hitting them too many times, and impact customer comfort -- and that would bring us offline.”

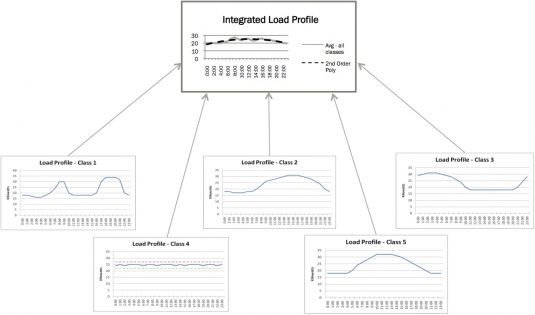

That requires spreading out the on-off signals across lots of devices for shorter periods of time, as well as classifying them into typical load profiles, such as what times during the day they need the most energy. Winstead calls that “the persistence of the load -- its ability to obtain the set-point in the dispatch instructions, and how long it can stay there. We value loads that can maneuver very quickly, up or down, and that can sustain over time.”

At the same time, each DSMP has to make sure at least some of its devices are on, and others are off, at all times. Otherwise, it wouldn’t have room to maneuver -- or “swing,” in PowerShift Atlantic’s terms -- its total load up or down when needed. That requires 36-hour advance forecasts of what all those heaters, chillers, pumps and other gear will need to do to perform their daily functions, and then defined upper and lower limits within that future window of time, to figure out, “at this point in time, you can move it up so much, or down so much, and that changes over the course of the day,” he said.

One more thing that’s required is real-time sensors and telemetry to each device, to make sure each one is “100 percent verifiable -- when you get the dispatch, you get back real-time information,” he said.

Add it all up, and it’s a set of aggregate load that can respond with enough flexibility and quickness to follow commands send down from Leidos’ central management platform. In the past two years of testing, the system as a whole has achieved a “very low error rate," Winstead said. "When we tell them to move in a direction, they break it up into the different end uses, and we get what we asked for -- and we get it when we expect to get it."

At the same time, breaking up the most data-intensive and time-sensitive tasks into discrete subsidiary units makes the system scalable, in a way that connecting tens of thousands of endpoints via direct, two-way central control and verification could well find hard to match. “We chose this multi-tiered, multi-layered approach for a lot of reasons -- but the chief reason is scalability," he said.

Who Pays to Play -- and Who Gets Paid

What can be done with this intelligent load management platform? The next six months of testing should put a number of use cases to the test, Winstead said. First, “It can actually manage, and follow a tracking signal, based on the renewable generation. We call that load shape management,” and it could help smooth out fluctuations from wind gusts and periods of calm across the region’s grid.

When that wind power exceeds grid needs, those water heaters, cold storage units and other virtual storage assets could store extra heat and cold to avoid forcing curtailment, a common problem in areas with high wind penetration. "We don’t want to spill the wind if we don’t have to,” he said.

Beyond that, “we could actually provide a service very similar to ten-minute spinning reserve,” or the fast ramp-up and ramp-down grid balancing now mainly performed by gas peaker plants. Those plants tend to run at 50 megawatts apiece, making the much smaller discrete loads available to the virtual power plant a more economical choice -- and the more that are available, the fewer new peaker plants may need to be built.

In fact, in a simulation that applied a theoretical 750-megawatt virtual power plant to New Brunswick’s 3,400-megawatt system, Leidos calculated a value of $3.5 million in annual savings from the resulting capacity cost reductions -- "and this is only one of many benefits," he said.

Admittedly, that’s a hefty assumption, given today’s mere 11.5 megawatts of dispatchable load. Even at its goal of 26 megawatts, PowerShift Atlantic’s budget of $32 million would add up to a pretty high price for the resource it provides. But that price includes the one-time costs of engineering and implementing the system, and if the architecture can scale as promised, adding more and more megawatts could come at a much cheaper price.

“You have to have significant participation to make this thing work,” he noted -- in other words, scale counts. But as long as each discrete set of resources can meet the needs of the central control system, “it’s infinitely scalable,” he said. That, in turn, could bring participation costs down to the point where utilities, grid operators, or third-party providers could start thinking about financial models to reward the customers willing to install or retrofit their equipment to play a part in the system.

“We’re hopeful this creates an energy trading market, so that the end-use customers can be remunerated for their contribution,” he said. “Today that’s not really the case" -- with government and utility funding paying for installation, customers that have been recruited and engaged in the project don’t have to pay to play. But we've seen how demand response markets in the U.S. and Canada have been able to offer paybacks that make customer investments worthwhile. Likewise, microgrid and virtual power plant projects, which take on load-balancing tasks at a smaller scale and for their own purposes, could find ways to participate, if they can meet the broader system's requirements.

"We are getting our eyeballs on the business case -- and there are so many business cases,” he said. “That ought to be pretty well known by March of next year, once we get the data from the systems.” Depending on the results, Leidos is definitely interested in building it into a production platform to put to use elsewhere, he said.

The results should be pretty interesting, both for the companies providing the hardware and software that can turn lots of disparate loads into grid-enabled resources, and for grid giants such as Siemens, General Electric, ABB/Ventyx, Schneider Electric and Alstom working on similar virtual power plant projects. While it's too early to say just how PowerShift Atlantic will compete, as a government-funded project, it should provide lots of valuable data to the smart grid industry at large.