A recent article in Nature suggests that Ambri has switched to a lithium-antimony-lead liquid-metal battery materials system for its grid-scale energy storage technology. The company did not confirm the new material.

Ambri is the battery firm that is based on the research of Donald Sadoway, MIT professor of materials chemistry, and inspired by the economies of scale facilitated by modern electrometallurgy and the aluminum smelter.

The big-battery startup has raised more than $50 million in venture capital from investors KLP Enterprises, the family office of Karen Pritzker and Michael Vlock, Building Insurance Bern, Khosla Ventures, Bill Gates and French energy giant Total, along with plenty of MIT and government grant money.

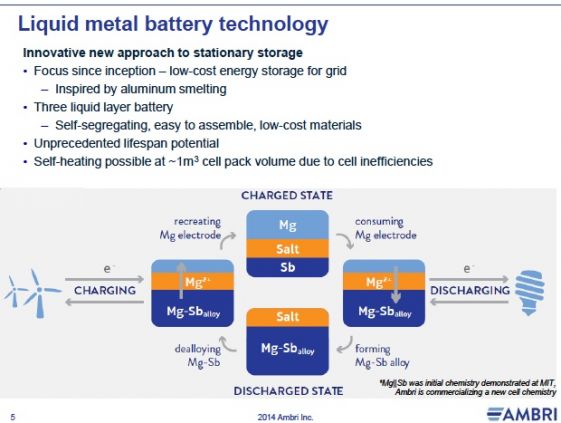

The three battery layers in the Ambri device are self-segregating, cheap to manufacture, and earth-abundant, according to the firm. The materials used in the original design were magnesium and antimony separated by a salt -- but "we needed higher voltage and lower temperature," said Ambri's CTO, David Bradwell, in a recent presentation, and so the firm developed a new, undisclosed chemistry with the help of ARPA-E funding.

But, as mentioned, a recent paper in Nature suggests that the team has been busy developing a lithium-antimony-lead formulation for grid-level energy storage.

Here are excerpts from the paper:

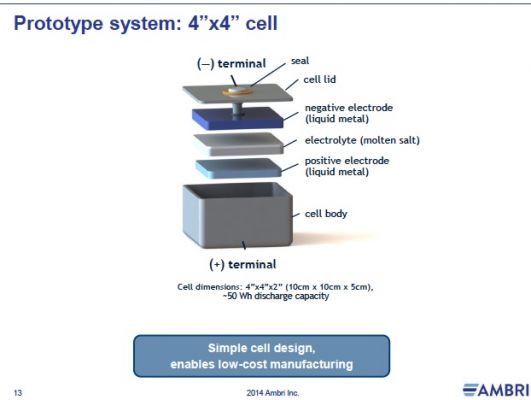

- This Li||Sb-Pb battery comprises a liquid lithium negative electrode, a molten salt electrolyte, and a liquid antimony-lead alloy positive electrode, which self-segregate by density into three distinct layers owing to the immiscibility of the contiguous salt and metal phases.

- The all-liquid construction confers the advantages of higher current density, longer cycle life and simpler manufacturing of large-scale storage systems (because no membranes or separators are involved) relative to those of conventional batteries.

- At charge-discharge current densities of 275 milliamperes per square centimeter, the cells cycled at 450 degrees Celsius with 98 percent Coulombic efficiency and 73 percent round-trip energy efficiency.

- Our results demonstrate that alloying a high-melting-point, high-voltage metal (antimony) with a low-melting-point, low-cost metal (lead) advantageously decreases the operating temperature while maintaining a high cell voltage. Apart from the fact that this finding puts us on a desirable cost trajectory, this approach may well be more broadly applicable to other battery chemistries.

FIGURE: Cell Schematic of Li||Sb-Pb Liquid Metal Battery

Source: Nature

Ambri's Bradwell would not confirm if this was the material in use, but did tell GTM in an email, "The performance of our cells now far exceeds even the strong cell performance described in the Nature paper (for example, our cells have reached a much lower fade rate of ~0.0002%/cycle)."

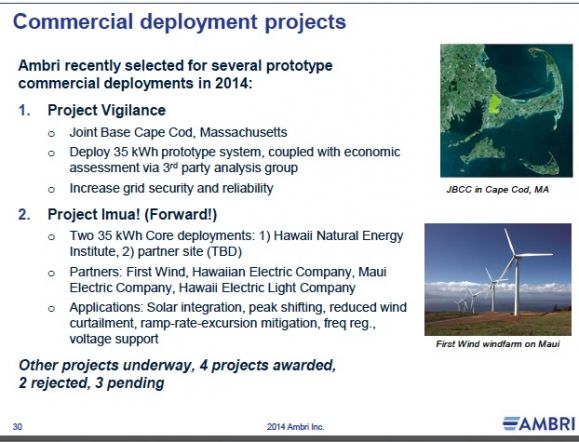

The firm is working on prototype storage systems in Massachusetts, Hawaii, New York and Alaska, with project partners such as First Wind, Hawaiian Electric, and Con Edison.

***

In March we reported on a presentation given by Bradwell at Infocast's Energy Storage Week. Here it is.

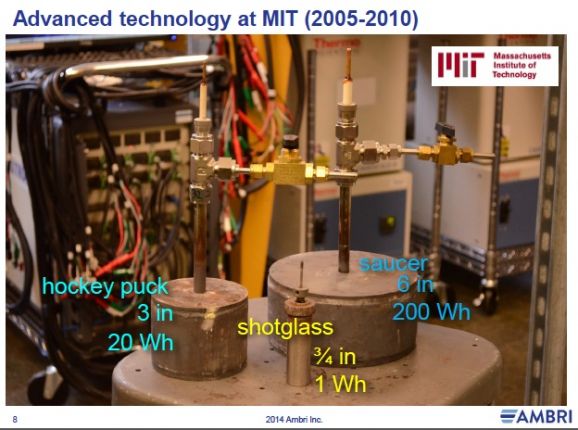

Prototype units started as the "shot glass," followed by the 3-inch, 20-watt-hour "hockey puck," and then by the 6-inch, 200-watt-hour "saucer." The commercialized product will use a 6-inch square.

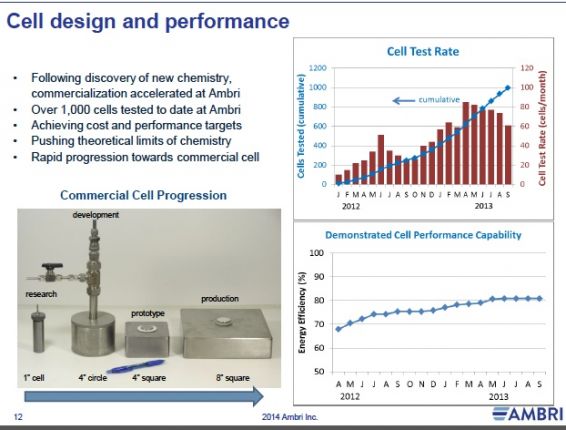

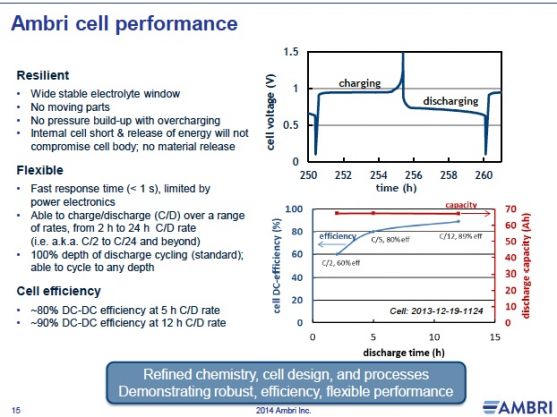

Bradwell notes that the batteries achieve 1,000 cycles of continuous deep cycling with negligible fade. There are no moving parts, pumps or valves in the design.

The cell is contained in a 4-inch-by-4-inch stamped stainless steel housing with no nanoscale microstructures or difficult-to-synthesize materials, according to the co-founder.

The cells have a DC-to-DC efficiency of 80 percent at a five-hour charge/discharge rate and an AC-to-AC efficiency of 70 percent to 75 percent.

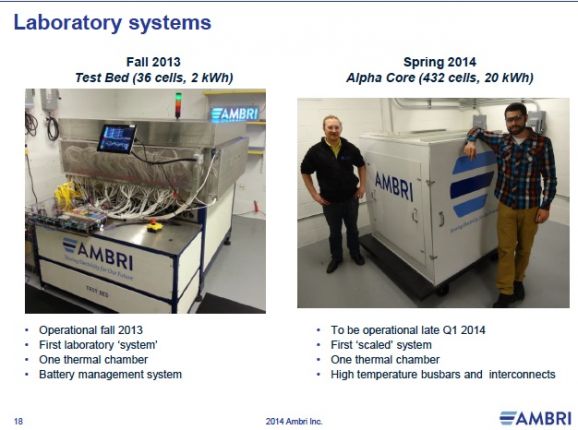

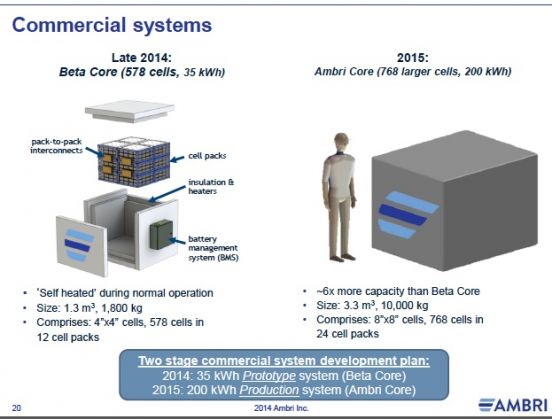

Ambri hopes to have its first scaled 20-kilowatt-hour units operational early this year, with 35-kilowatt-hour commercial units coming in 2015. A larger system will reach 200 kilowatt-hours in 3 cubic meters. The 10-ton weight of that unit will serve as an effective theft deterrent, joked Bradwell.

The company's pilot project in Hawaii will have two cores installed this year in partnership with First Wind and HECO, with funding from the DOE- and ONR-sponsored Hawaii Energy Excelerator. The goal is to improve integration of solar power and reduce wind curtailment.

Another project at Joint Base Cape Cod will see deployment of a 35-kilowatt-hour prototype to improve grid security and reliability.

Bradwell noted that all manufacturing processes and robotic cell assembly had to be developed by Ambri. He claims that the technology has a lower manufacturing cost and lower employee-per-square-foot-of-factory ratio than that of lithium-ion battery technology. The CTO also suggested that Ambri's pricing will fall between that of pumped hydro and compressed-air energy storage.

MIT's Don Sadoway on Ambri technology