We just had a call with William Sims, CEO of Joule Biotechnologies. A very personable, charismatic, yet down-to-earth guy.

Yet, the science behind his designer fuel is almost from another world relative to the biofuel approaches in existence today. In order to understand what Joule is manifesting, a brief recap of a few other processes is required:

First-generation biofuels transform food crops into either ethanol (fermentation) or biodiesel (transesterification). Such biofuels now displace more than 2% of global petroleum consumption and production is in the tens of billions of gallons per year range (see Ethanol and Looming Blend Wall). While first-generation biofuels have begun to make a dent in the oil markets, their capacity to scale much further beyond current levels is impacted by the "food vs. fuel" debate, infrastructure incompatibilities, and questions about whether the carbon and energy balance of producing these biofuels is net positive. (See An Inconvenient Truth: Biofuels Have a Carbon Footprint.)

Second-generation cellulosic biofuels by and large do not compete with cropland (ideally) and food sources. In utilizing the lignin to co-generate electricity, cellulosic biofuels have a better environment footprint relative to first generation fuels. Some companies such as Amyris are also breeding genetically modified organisms to secrete hydrocarbons, thereby cutting out some refining processes. There are significant questions surrounding the logistics of obtaining millions of tons of biomass of different shapes and sizes as well as the costs of breaking down the biomass into fermentable sugar (see Denmark Makes A Stab for Biofuels Greatness). Second-generation biofuels are not commercial yet, however, the first commercial facility is expected to be running by late 2010. The total amount delivered, however, will be small.

Third-generation algae is a qualitative leap from first- and second-generation processes. Basically, certain strains of algae can grow up to 50% of its body weight as a lipid that can be transformed into a variety of "drop-in" hydrocarbons (jet fuel, diesel, gasoline, etc.). Algae do not require freshwater or cropland and consume C02 as a feedstock. The big problem with algae is that the numerous steps required in growing, harvesting, drying, de-watering, extracting the oil, and transforming the oil into fuel costs somewhere between $8-$30/gal. While costs are expected to come down precipitously in coming years due to the consolidation of these steps (see Biofuels 2010: Spotting the Next Wave), many experts in the field do not believe that we will see commercial-scale algae biofuels for another 8-10 years.

This brings us to Joule Biotechnologies and its competitors, who are attempting to utilize proprietary microorganisms that turn photons, water, and C02 directly into drop-in fuels. ARPA-E gave $23.7 million to a couple of companies like BioCee in this space last year. ARPA-E calls it "direct solar fuel" because you don't have to wait millions of years and employ tectonic forces to get fuel. But we prefer Biofuel 3.5.

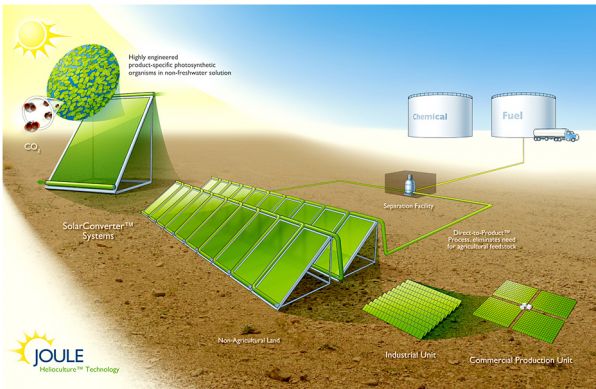

Although Joule has remained relatively tight-lipped about the specifics of its technology, its systems have a "solar converter" which can be thought of as solar walls (but not cells) that absorb photons while managing optical density so their proprietary bugs get all the photons they need.

The company uses a "helioculture" process that amalgamates the photons with captured waste C02 and brackish water to optimize photosynthesis. Yet, the modification of the organism is such that rather than using the energy available from photosynthesis to grow, the organisms direct the energy for production of fuel.

As such, the process generates more energy than it consumes and does not have any of the issues of growing, harvesting, and converting biomass into energy (because it does not use biomass), thereby radically reducing operational costs.

The company expects to produce diesel at $30/bbl at the nth plant of commercial scale.

Currently, it is building out its first pilot facility, which will come online in 2010. Joule will create a demonstration plant in 2011 and hopes to break ground on a commercial facility in 2012.

The company is targeting 25,000 gallons of ethanol per acre per year and 15,000 gallons of diesel per acre per year.

Some in the industry are skeptical of Joule's claims.

For example, renowned NASA scientist Dr. Aaron Baum writes on his blog that these claims "should be a red flag for investors... If the critters can be kept alive indefinitely producing the product, then the lipid fraction is effectively 100%. This still does not get you close to their claims for any realistic biological photosynthetic mechanism."

Not helping Joule's case is the fact that a number of high-profile advanced biofuel companies over-promised and under-delivered in recent years (see 8,751,428 Gallons of Algae Per Acre!), further eradicating credibility within the nascent industry.

Yet, when I asked him about the formidable challenges that his company faces, William Sims was quite humble. He admitted that while Joule has shown incredible results in the lab, "it is true that we have not shown that it works at a large scale."

The company is funded by Flagship Ventures and has enough capital to build two pilot facilities this year (one pilot plant will produce diesel, the other ethanol) and the demonstration plant in 2011.

It could be a game changer if it works. If it works.

Michael Kanellos contributed to this article.