Coal-powered electricity generation is not going away anytime soon.

Coal generates approximately half of the electricity in the U.S. It's relatively cheap and plentiful and has driven the West's economic and social surge over the past century or two. China and India will depend on coal to power their economies in the coming decades.

Solar and wind power have a long way to go before they eclipse coal power. The best those renewable energy sources can do for now is to prevent additional coal plants from being built. That leaves us with the existing fleet of aging and polluting coal plants.

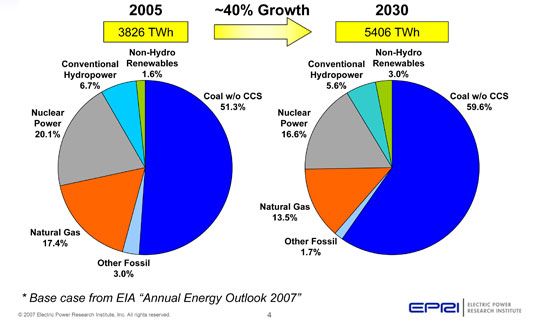

The Electric Power Research Institute and the EIA see the electricity generation picture like this:

There are efforts to work more intelligently with coal that include underground coal gasificiation (Laurus Energy), coal-to-liquids (Accelergy and Biocee), and carbon capture and sequestration (CCS). (We've covered CCS in detail here. There's a detailed EPA report on CCS in PDF format here.)

And then there are companies like Skyonic and Calera looking to scrub the flue gas of existing coal plants and extract or convert the carbon dioxide and toxins from that waste stream -- in an energy-efficient and profitable manner. The Calera process is not without its controversy.

Michael Kanellos has reported on Skyonic a number of times (see Carbon Capture on the Cheap).

Skyonic's process revolves around mixing sodium hydroxide with flue gases. The firm's SkyMine system performs three functions.

- It acts as SOx/NOx scrubber, something coal plants already have to install. It scrubs 99.9 percent of the SOx gases, 99 percent of the NOx and 97 percent of the mercury, according to the CEO.

- It gets rid of 96 percent of the carbon dioxide that flows through it.

- It extracts saleable minerals: sodium carbonates, sodium bicarbonates, magnesium carbonates, hydrogen, chlorine and eventually metals like germanium that go up the stack when coal is burned.

In the end, the only materials released to the atmosphere are nitrogen, oxygen and water, and the water can be recycled for industrial operations.

Skyonic received a $25 million grant from the Department of Energy in July of this year to build the Capital-SkyMine project, the commercial-scale expression of this technology.

Update

I spoke with Skyonic's CEO, Joe Jones, to get an update on the startup's progress.

In April, Skyonic installed a small demo system at Capital Aggregates in San Antonio, Texas, that state's largest cement plant. The demo unit is a 32-foot column running a large amount of CO2 and producing bicarbonate of soda. The firm is looking to transform that into a commercial-scale plant in early 2011.

The company has gained another potential market -- algal biofuels. "Algae biofuel producers have made inquiries," according to the CEO, because bicarbonate of soda apparently speeds algal maturation and also triggers lipid growth. Feeding algae sodium bicarbonate instead of raw carbon dioxide eliminates many of the plumbing and circulation issues that come with pumping CO2 into algae ponds.

Another use for the potential massive amount of bicarbonate of soda is as flux in the production of glass, as it lowers the melting point of sand.

An Alternative to CCS with a Better Energy Balance

In the words of the CEO, "We are not fans of CCS. Mineralization is the way to get rid of CO2," adding, "You don't have to do open-heart surgery with the plant." Their process does not require pumping or geological storage. Since it is a post-combustion process, existing power plants and industrial plants can be retrofitted with the Skyonic equipment.

The big question with this type of technology is the energy balance. Does the process use an enormous amount of energy to extract the CO2? How much energy goes into producing Skyonic's starting base material, sodium hydroxide?

"The DOE's assessment of our process is the most important and the DOE says the process has a negative carbon footprint," in the words of the CEO.

"It consumes CO2. Period."

"Our current carbon penalty is 43 percent and our goal is 20 percent," said the CEO, "while the CCS penalty is in the range of 25 percent but does not include compressing and transport, which places it above 44 percent."

Jones also updated Greentech Media with news of a technology that might address some of the energy balance issues in the production of the sodium hydroxide base. This new technology transitions from the originally electrolytic technology to a thermolytic splitting of salt to generate the base. Patents have been filed and the potential exists to use the waste heat from the coal plant to fuel production of the feedstock.

Skyonic's Business Plan

Skyonic's business plan has a number of angles. The company will sell equipment to utilities and industrial manufacturers, as well as offer it as a service. The startup will also license a reference design into the chemical industry for chemical producers.

"We are equal-opportunity carbon reduction proliferators," Jones said.