Water utilities and industrial companies are increasingly looking for efficiencies in wastewater cycles. One company that is focused on that mission, Pasteurization Technology Group (PTG), just raised $5 million in series A financing. The new round of money will be used to expand sales, especially in the industrial sector.

PTG’s first clients, however, have been in the municipal space. The San Leandro, Calif.-based company solves two of the pain points in wastewater treatment, according to Greg Ryan, CEO of PTG, no matter what type of facility.

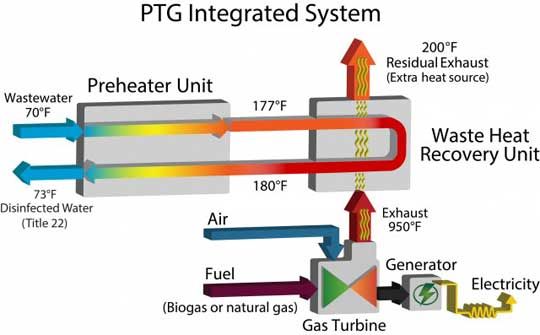

As the organic material in the wastewater breaks down, it gives off biogas such as methane, which is usually flared. At the very end of the treatment process, the water needs to be disinfected before it can be discharged. PTG addresses these two disparate problems in one system, and the technology "can save huge sums of money,” said Ryan.

In Ventura, Calif., where PTG’s system is in late-stage pilot, the municipality is saving nearly $1 million annually. The biogas is used to drive a turbine in Ventura that provides electricity for about 20 percent of the plant’s power needs. The amount of biogas varies, so for some other plants, the gas could meet all of the power needs or only a fraction. In California, PTG’s technology has already been certified under Title 22.

Many other companies, primarily those working with fuel cell technologies, are also looking at harvesting the biogas to cut energy requirements, “but they don’t even touch the water component,” said Ryan, who argued that his company is unique in addressing multiple problems.

Down at the other end of the treatment plant, most plants have historically used chlorine dioxide, chloramines or UV light. UV light is the best, but can be difficult to treat the water that sits at the bottom of a tank. Some researchers have concerns about chlorinated byproducts in the environment and their effects on reproductive health.

PTG takes a relatively old-fashioned approach: heat. The idea of using heat to disinfect has been around for a long time, but the cost of heating wastewater in large amounts has typically been seen as too expensive.

To overcome the challenge, PTG takes the waste heat coming off of its biogas turbine to heat the wastewater to a temperature that disinfects the water stream. The energy in the hot water is also then reused to bring up the temperature of the water into the incoming stream.

The closed-loop system could be a particularly good fit for the food and beverage industry, such as fruit producers or breweries. (PTG is already piloting with a brewery and a potato chip manufacturer.) Ryan said that the industrial market would be the first focus, but added that “it is crystal-clear to us that the municipal wastewater market exists on a gargantuan scale.”

PTG has about a dozen proposals in the pipeline currently and expects about eight or nine projects by the end of the year. There are also many other pain points in the wastewater business, such as sludge, but PTG said that it wants to stay focused on its current approach before taking on other challenges. It is already looking for international partners

That doesn’t mean there isn’t space for partners, big -- like Siemens or GE -- or small, like the many other startups tackling other wastewater challenges. Ostara, for instance, is taking phosphorus out of sludge to resell as high-grade fertilizer, while Oberon FMR harvests bacteria from wastewater streams at food-processing plants to turn into feed for fish farms. There are endless startups with ideas on how to turn the concept of wastewater into a water recycling stream or to extract enough energy from the process to run an entire plant.

Kennington joined the Series A, which was led by EIC Ventures. EIC has previously invested $1 million in PTG.