A Japanese research group developed a new oxide negative-electrode material that can enhance the capacity, lower the cost and increase the life of lithium-ion rechargeable batteries.

In addition, the research group, which consists of members of Japan's Advanced Industrial Science and Technology (AIST), developed a synthesis method that can be used at a relatively low temperature of 200 to 300 degrees Celsius.

The newly developed material -- chemical formulation of H2Ti12O25 -- is a kind of titanium oxide. It can increase the energy density to a level 30% higher than lithium titanate (Li4Ti5O12: LTO), which is a commonly used oxide negative-electrode material. Specifically, the charge-discharge capacity (per the weight of oxide) was enhanced to about 225mAh/g, which is higher than the 175mAh/g of LTO.

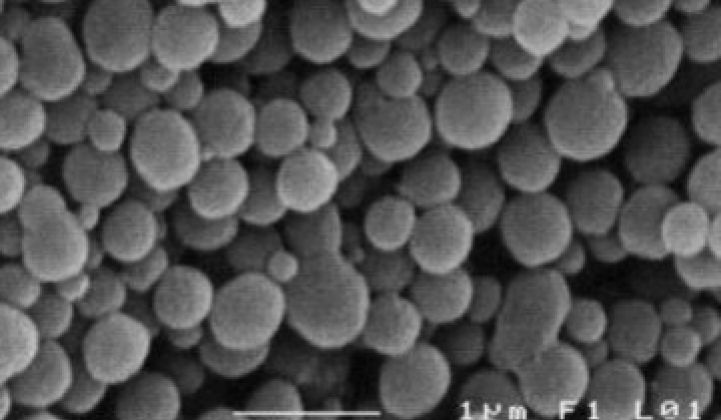

According to AIST, the new negative-electrode material can lower costs more than LTO because the new titanium oxide does not contain lithium. (The picture shows lithium titanate particles and did not come from AIST's work.)

A number of companies and institutions -- IBM, Contour Energy Systems, Envia Systems, Zeptor, Sakti3 and the solid state battery crowd -- are tinkering with the electrodes (anodes and cathodes) in batteries to improve power delivery or, more importantly, energy density and safety. While some may license their electrodes, some of these companies will have to make batteries. (Others like Porous Power are, by contrast, working on passive components for batteries.) AIST will likely license and it has a wealth of local companies, such as Panasonic, Sharp, and Toshiba, that potentially could be interested. Of course, the technology will have to become more robust first.

In the meantime, Toyota and others have begun to explore mining for battery materials in recyclables.

For more on the story, please go to TechOn.

***

Michael Kanellos of Greentech Media contributed to this story.