A year ago, MiaSolé appeared to still be struggling mightily to bring its thin-film panels to the market. After keeping a low profile for most of this year, the startup said it has crossed that all-important milestone.

The Santa Clara, Calif.-based company said it not only has started shipping to 30 customer sites in Europe and the United States, but it already has seen completed installations using its products.

In a brief announcement, the company's CEO Joseph Laia said the company plans to boost it factory capacity in 2010. He didn't disclose more information about the factory plan, customers or installations. We've put in calls to the company.

Although the press release didn't disclose its current factory capacity, company executives told Greentech Media last month that its factory could produce 60 megawatts of solar panels per year. The company plans to add another 60 megawatts later.

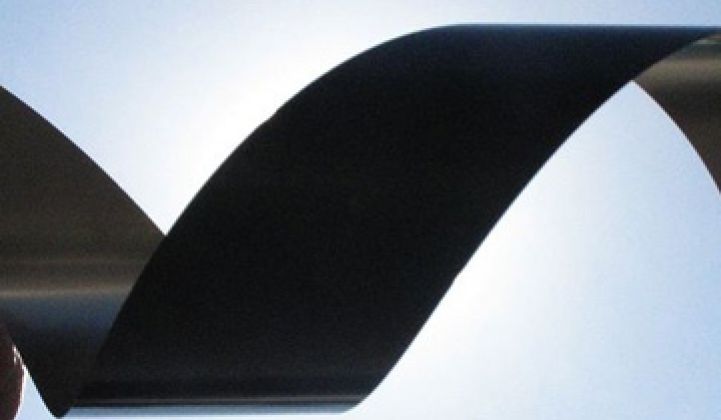

MiaSolé makes solar panels using a compound of copper, indium, gallium and selenium (CIGS), a fairly new type of solar panels for the market that is dominated by panels made with crystalline silicon.

The company is among a group of CIGS startups in the U.S. that have raised hundreds of millions in venture capital each in recent years, but struggled to commercialize their technologies.

The company saw its top scientist leaving to join SoloPower late last year (MiaSolé's Chief Researcher Defects to SoloPower). MiaSolé backed out of two government-funded projects early 2008 because it wanted to focus on improving the efficiency of its solar cells and working toward commercial production.

The two government projects would have required MiaSolé to spend its resources on embedding its solar cells into building materials (see MiaSolé Drops Out of DOE Program). Developing building integrated products presented tough technical challenges back then and still does today.

Like many other startups, MiaSolé aimed high and didn't deliver for a while. It thought it could start selling its CIGS solar panels starting in 2007. Then a management shakeup saw the departure of its founder David Pearce in 2007, as well as layoffs by the end of that year.

Laia took over the CEO post in 2007, when the company was producing cells that could only convert 5 percent of the sunlight that falls on them into electricity (see MiaSolé Clears the Air).

By the middle of 2008, the company had boosted the efficiency by quite a bit. It reported it was able to produce panels with 10.2 percent efficiency (see NREL Confirms MiaSolé's Solar Panel Efficiency). At the time, the company said it had installed two production lines of 20 megawatts each, but it hadn't started commercial production.

The company then stayed quiet and declined interview requests.

It began issuing press releases this month, first announcing that its solar panels have received safety and performance certifications from Underwriters Laboratories.

MiaSolé then announced that it had hired Kevin Eassa as its vice president of manufacturing.

Some of its fellow CIGS panel manufacturers have boosted their production capacities, improved their technologies and attracted new customers in the past year. Nanosolar from San Jose, Calif., Global Solar Energy in Tucson, Ariz., and Solyndra in Fremont, Calif., are examples (see Nanosolar Boosts Cell Efficiency, Starts Mass Production and Global Solar: BIPV Market or Bust).

Solyndra also snagged a $535 million federal loan to build a second factory that would eventually have 500 megawtts of annual capacity (see Solyndra: Fab 2 Construction Begins).

Meanwhile, Solibro in Germany, plans to boost its factory capacity to 45 megawatts from 30 megawatts by the end of the year. The company, a subsidiary of Q-Cells, has been producing solar panels at near 11 percent average efficiency.

Photo: A MiaSolé CIGS solar cell.