MiaSolé, the number-three producer of CIGS thin-film solar panels (behind Solar Frontier at 577 megawatts in 2011 and Solibro at 95 megawatts), has been somewhat uncommunicative in the last few years. But the arrival of a new CEO seems to have opened up the company to the outside world in a small way.

In a rare public appearance, the firm's VP of Process Technology, Atiye Bayman, presented to the Silicon Valley IEEE PV Chapter at PARC in Palo Alto, Calif. last month. Bayman has been at MiaSolé over the course of three CEOs.

Her presentation highlighted the solar panel vendor's reliance on PVD throughout the entire production process.

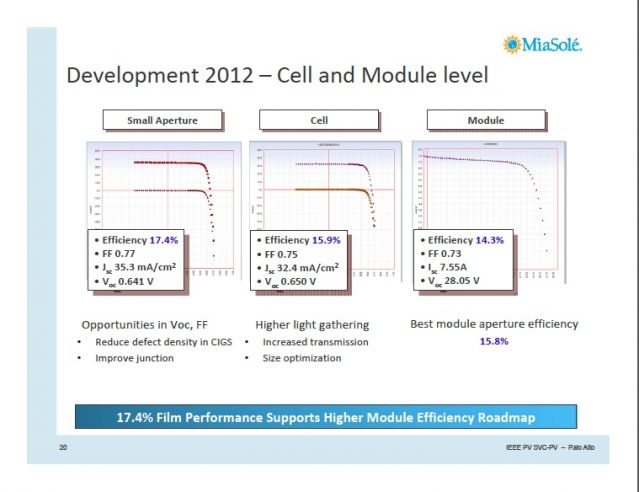

The firm just announced a 17.3-percent-efficient champion device, while the "manufacturing process for 14 percent efficiency is now in production." The firm claims that 14 percent in production is a world-leading figure, as is the claimed $0.50 per watt capex.

Here are the slides:

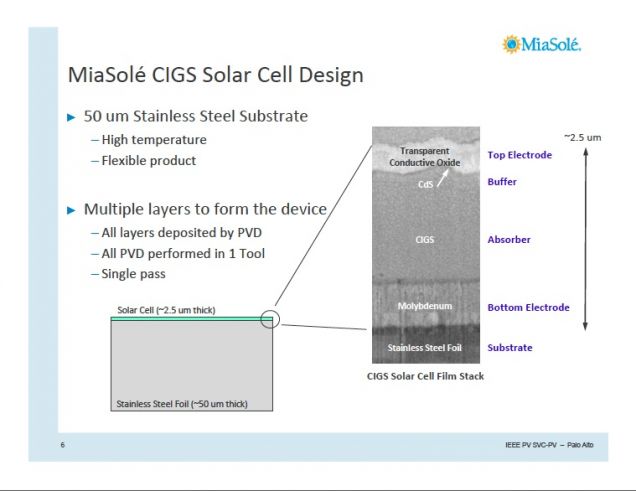

MiaSolé's thin film stack rests on a 50-micron stainless steel foil substrate. The stainless steel allows processing at high temperatures and allows the potential for flexible panels. Bayman stressed that product success is tied to LCOE and the ability to maximize energy generation. The cadmium sulfide (CdS) buffer layer is sputtered. Bayman noted that sputtered CdS is very rare, saying, "We had to learn how to sputter CdS on CIGS and then do the work to optimize thickness and transparency."

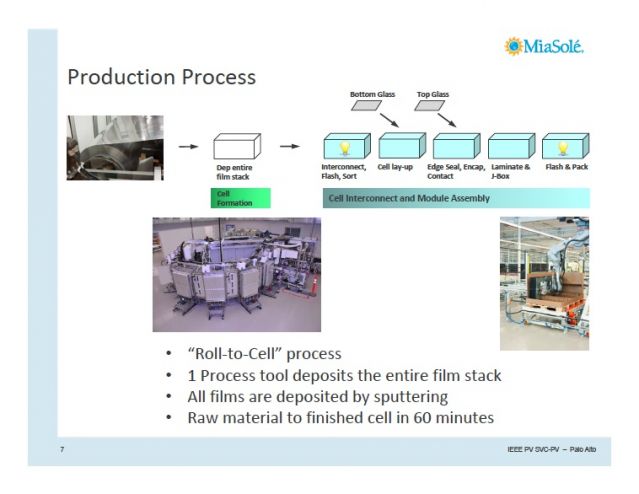

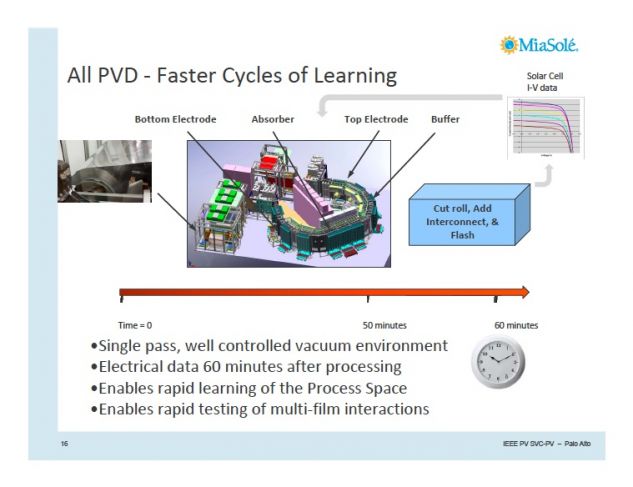

The thin film stack is produced in a "single-pass deposition" using a single tool that is entirely PVD. The stack is created in 60 minutes from roll to flash-tested cells. Production is not in a clean-room environment.

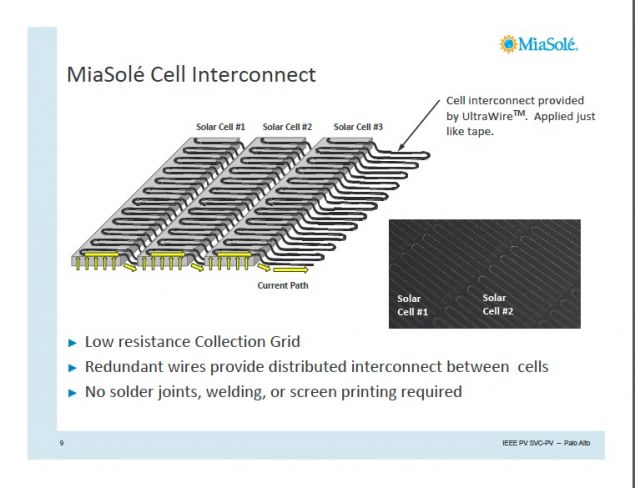

The cell interconnect tape has wires weaved onto it that make contact with the top electrode. According to Bayman, the interconnect tape provides a low-resistance connection with no solder, no screen printing, and no welds.

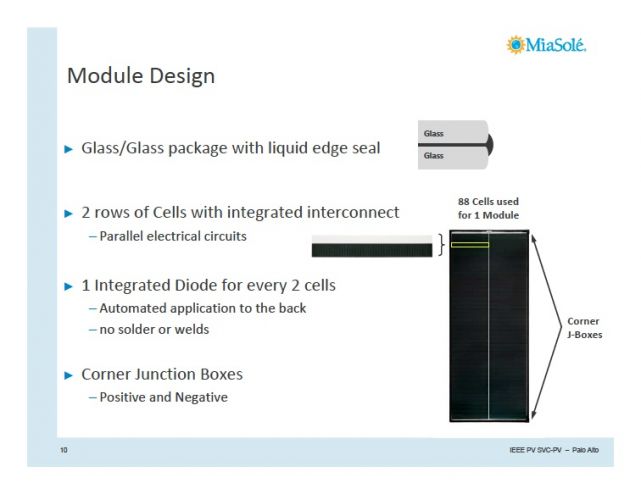

A liquid edge seal keeps moisture away from the 88 cells that consist of 2 serial-connected strings of 44 cells. There is one bypass diode for every two cells and one positive and one negative junction box per panel. That makes one bypass diode for every 3 watts versus one for every 80 watts for crystalline silicon modules.

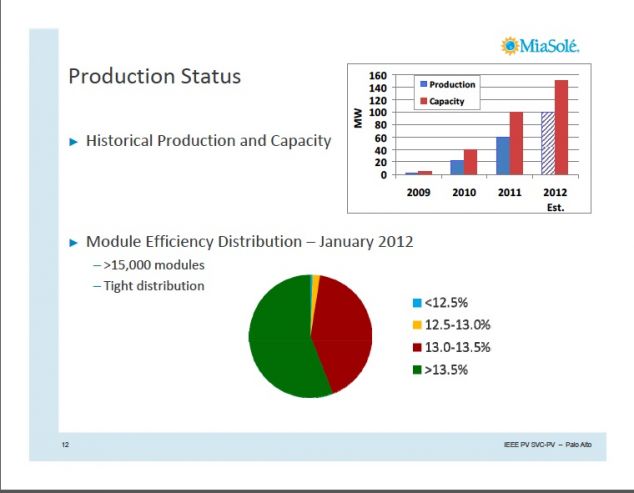

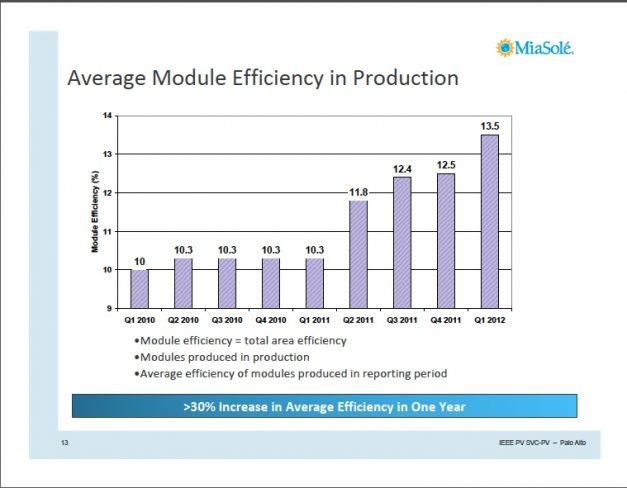

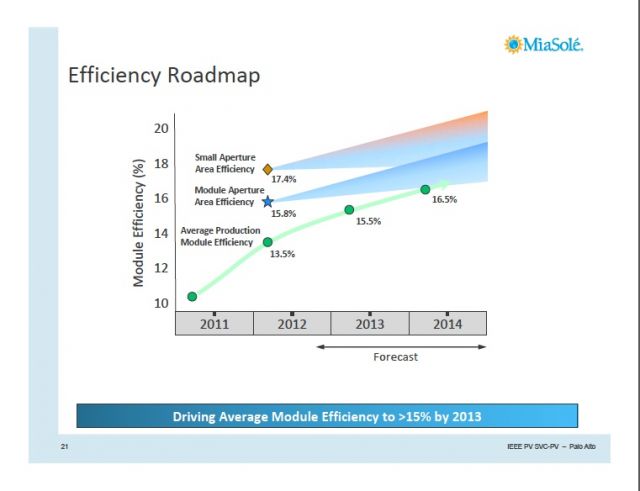

Bayman cited an average module efficiency of 13.5 percent, with more than half of the production greater than 13.5 percent efficiency. She claimed that all PVD processing means faster cycles of learning limited mostly by the time needed to analyze the material.

The all-PVD machine in the slide below occupies approximately 45 feet by 45 feet.

Contaminants in CIGS correlate with defects. Defect density also correlates with open circuit voltage. Sources of contamination include the stainless steel, nickel, iron and chromium, and other materials.

The best module produced on the current production equipment had an efficiency of 14.3 percent. Bayman expects to see 15.5 percent in 2013 and 16 percent in 2014.

Although the CIGS thin-film solar panel startup has made some technical and business progress, it is still bleeding cash in a pitiless market with a set of VC investors who are likely impatient for an exit. Investors in MiaSolé include Kleiner Perkins Caulfield & Byers, Firelake Capital, and VantagePoint Capital Partners. Factory capacity will be about 150 megawatts by the end of the year -- all in Silicon Valley.

The firm has raised in the neighborhood of $500 million in VC funding since its founding in 2004. MiaSolé raised most of a $125 million round F in February at a pre-money valuation of $550 million in 2011. One would imagine future valuations will be far less (Nanosolar's recent funding came at an absolutely ruthless valuation). New investors included Voyageur Mutual Funds III, joining existing investors Kleiner Perkins, Firelake Capital, and VantagePoint Venture Partners. Board members include KP's John Doerr, Firelake's Marty Lagod, VantagePoint's Stephan Dolezalek, and Rob Chandra of Bessemer.