Just came back from a trip to LS9's pilot facility in south San Francisco.

Fascinating company.

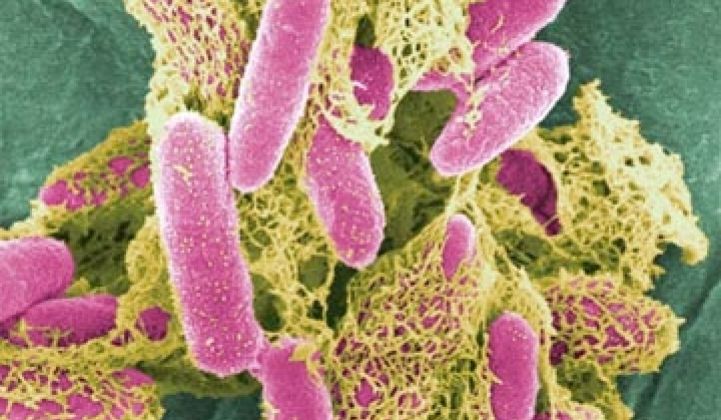

If all goes according to plan, within a few years the company will turn E. coli into a "drop-in" renewable diesel fuel.

The company already produces a diesel that meets the American Society for Testing and Materials (ASTM) standards for road use in the U.S.

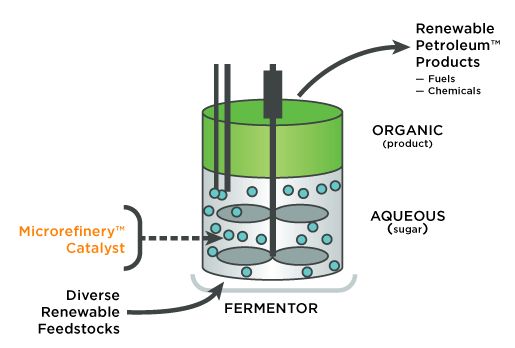

The technology is pretty straightforward. LS9 uses any sugar source (though initially it will use sugar cane due to the favorable economics and logistics of sugarcane compared to cellulosic sugars) and feeds genetically modified E. coli bacteria (the same kind found in our guts that helps digest sugars into energy) a combination of sugar, nutrients, methanol, and enzymes in a low-heat environment.

Voila! In a one-step conversion process, the bug secretes the oil. Since the oil is lighter than water, it rises to the surface where it can easily be skimmed. The total lifecycle from when the microbes are first fed sugar to the secretion of the fuel is three days. A variation on the process that involves a centrifuge is also being tested.

At commercial scale, LS9 anticipates breaking even with $50/bbl crude oil.

Skeptical?

Considering the plethora of companies that have come out of stealth mode over the years that over-promised and under-delivered, I don't blame you (see GreenFuel Technology Closing Down).

But LS9 has some interesting dynamics working in its favor.

In 2010, it closed a $25M Series C equity round that was led by Chevron Technology Ventures' venture capital arm, CTTV Investments, a development that we announced in September 2009 (see Chevron Invests in LS9). Chevron happens to know a thing or two about the logistics of petroleum infrastructure engineering -- a skill set that many advanced biofuel startups lack.

Additionally, LS9 has signed a memorandum of understanding (MOU) with Proctor and Gamble to produce "green" surfactants -- chemicals that are used in detergents.

In early February 2010, LS9 disclosed that it had purchased an eight-acre demonstration-scale facility in Okeechobee, Florida that will be capable of producing 50,000-100,000 gallons of diesel and biodiesel fuel. This facility was being sold in a bankruptcy fire sale for less than $2M -- even though it has a book value of $80M.

LS9 is currently exploring whether the facility could be significantly retrofitted for commercialization. As it stands now, the demonstration facility will be up and running by mid-2010 and by the beginning of 2011, the company intends to determine whether the plant is commercially scalable.

Add one more factor in LS9's favor: one of its founders is Chris Somerville, the director of the Energy Biosciences Institute at UC Berkeley and one of the major scientific figures in biofuel. He's also close to Energy Secretary Steve Chu and Steve Koonin, the head scientist at the DOE. The three were behind BP's $500 million donation to Berkeley and the University of Illinois to study biofuels.

If the company's technology and facilities prove to be commercially scalable and the financing is in place -- both big ifs -- LS9 could be producing 10-12 million gallons of renewable diesel fuel by 2012.

While 10 or so million gallons is a drop in the bucket compared to the tens of billions of gallons of petroleum diesel that the U.S. consumes (see EPA Issues Renewable Fuels Standards), the recent developments by LS9 and others (see Solar + Water + C02 = Diesel?) illustrate that third-generation biofuels that contain the same chemical characteristics as petroleum hydrocarbons are moving from the realm of science fiction fantasy to impending reality.