With its rapid economic growth and expanding population, China is ushering us into the future. It’s even beginning to lead the world in cleantech innovation, a pioneering shift with which the American entrepreneurial engine should compete. As we critically evaluate our domestic energy options in light of recent global catastrophes, we should take a page from China’s economic playbook: the twelfth edition of the Five-Year Plan, China’s master blueprint for economic growth.

The plan, released last month, reveals that China is diligently preparing for record breaking levels of water usage by setting stringent limits on energy consumption. In the last decade, China’s water reserves have dropped by thirteen percent. This has led the Chinese government to consider that water -- more than anything else -- will limit the supply of energy necessary for economic growth. Even the production of coal, China’s most important natural resource, is now constrained, as it is the single largest consumer of fresh water. This is the critical point in the energy-water nexus: the point at which energy production is constrained by water availability.

China, like many other countries around the world, is turning to desalination, which produces drinkable water from seawater. Over 524,000 tons of desalinated water are being produced in China every day. China has realized that desalination is the only viable, scalable solution for increasing fresh water supply. But to unlock desalination’s full potential, new fuel-efficient technology and improved affordability is needed.

Currently, the dominant technology in seawater desalination is reverse osmosis (RO). Over the last 30 years, RO technology has improved dramatically in energy use and cost. In 1980, seawater RO required approximately 8.1 kWh of electricity for each cubic meter of potable water (m3) it produced. By 2001, it had dropped to less than 3kWh/m3. Since then, improvements have been incremental. Current electricity use in seawater RO plants, including pretreatment, is approximately 3.73 kWh/ m3, with approximately 2.41 kWh/ m3 for the RO separation. The lowest demonstrated use for RO, excluding pretreatment, has been just below 1.6 kWh/ m3. This is a phenomenal achievement, as the minimum thermodynamic requirement for desalination of seawater is close to 1 kWh/ m3. The full potential of RO has been realized. Unfortunately, there is not much room for improvement.

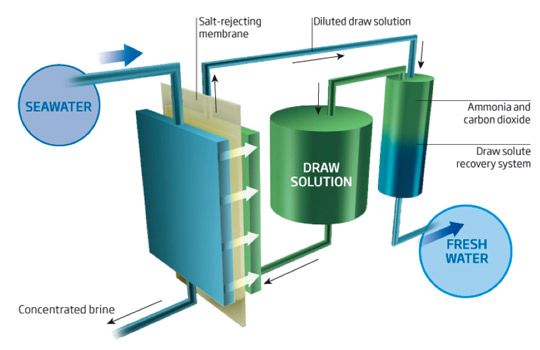

An alternative desalination process called direct or forward osmosis (FO) uses membranes, as RO does, but instead of pressurizing seawater with electricity and forcing it through the membrane, FO utilizes the natural process of osmosis to reach the same goal. (At Oasys Water, we are developing FO technology called Engineered Osmosis®.)

In FO, a special solution of salts is used to generate osmotic pressure higher than that of seawater. This draw solution causes the water in the seawater to flow across a membrane. No hydraulic pressure is required. Low temperature heat is then used to recycle the special solution of salts, leaving only the fresh water behind.

The true economic value of forward osmosis desalination comes from the kind of heat that is used: waste heat. Steam from a power plant that is no longer useful to make electricity can be used to make fresh water from the ocean. The amount of electricity the power plant produces remains the same, as does the amount of fuel the plant consumes.

The electricity needs for forward osmosis desalination are very low, approximately 0.24 kWh/ m3(excluding pretreatment) in municipal-scale plants. With FO, fresh water can be produced from the sea using approximately one-tenth the fuel or electricity required by other desalination methods. FO desalination also dramatically lowers the total cost of water, since energy costs can be up to half of the total water cost of seawater RO.

There is a misconception that because RO uses fewer kilowatts of electricity than the kilowatts of heat that FO uses, a thermal approach to desalination like FO is not as efficient as RO. But FO uses low temperature heat that has no other purpose, while RO uses electricity or fuel that is costly, negatively impacts the environment, and could be used in other ways. Each cubic meter of fresh water produced in a typical RO seawater desalination facility requires the combustion of approximately 0.6 m3 of natural gas or 1.15 kg of coal, or the use of renewable electricity sources that would otherwise displace the use of this amount of fuel. Forward osmosis uses 90% less fuel than RO. FO offers a solution to the currently unsustainable exchange of fuel for water in desalination processes that are used today.

The role of desalination in supplying water for energy will continue to expand. To put our domestic water needs in perspective, look at the water footprint of the power industry, a sector that uses 40% of the United States' freshwater. Using electricity generated from a natural gas combined cycle plant as a baseline, we consume 180 gallons of water per megawatt of electricity.

As we transition to cleaner alternatives, the options will be limited -- biomass combustion consumes 1.7 times the amount of water per megawatt; nuclear power, two to four times the water; solar thermal, four to five times the water; and geothermal, eight times the water. Only solar PV and wind, both unreliable sources of base load power, require less water than natural gas.

Shale oil, regarded as the primary source of future domestic transportation fuel, requires two to five gallons of water for every gallon of refinery-ready oil produced. Increasing the number of sources of water through desalination is vital. Since more than 60% of our energy is wasted as heat, waste heat is the logical source of lower-cost energy to meet our water demand.

If China is an indicator of what is to come, then the U.S. should similarly expect -- and be prepared for -- the time when economic growth is slowed not by energy supply, but by water availability. We should ensure our national and personal security by investing aggressively in desalination and other alternative ways to increase our fresh water resources.

***

Aaron Mandell is the CEO and Rob McGinnis is the CTO of Oasys Water.