Much has been written lately regarding the market for rare earth elements. Their use in permanent magnet generators, motors, fuel cells, lasers, and power electronics, as well as other applications, has been well documented. However, as people have looked at the constraints being placed on the global supply of rare earth elements, sensationalism has given way to truth in certain cases. There are ways to innovate our way out of the dilemma.

Permanent magnets (PMs), such as those which are utilized in wind turbine generators, are typically neodymium-iron-boron (NdFeB) magnets. These are the most popular types of magnets because of the magnetic flux density characteristics, and ultimately the generator efficiency, that is achievable.

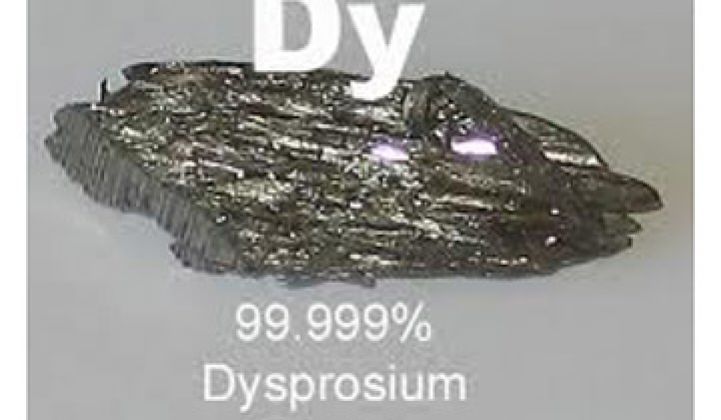

Additionally, other heavy rare earth elements, such as Dysprosium (Dy) and Terbium (Tb), are used in combination with traditional PMs to control temperature, due to the high rate of thermal absorption and dispersion of these elements. However, Dy and Tb are much less abundant, or indeed more rare, in the global supply chain and are more expensive to refine. As opposed to Nd, which is more readily available, Dy and Tb are likely to be the subject of supply constraints in the future, as there is a lack of global refining capacity at the present time.

Conventional PM generators must use high-temperature-grade magnets because they must control temperature increases while maintaining an air gap that is millimeter-sized in order to achieve optimal flux and efficiency. The heat in the generator stator (or the rotor, in the case of certain designs) could easily rise to a point that is higher than the temperature rating on the magnets. Magnet flux will be degraded if adequate cooling cannot be employed.

It has been reported that the expected price increase of Nd is to be much lower than the expected price increase of Dy and Tb, due to the supply and refining constraints. The key to overcoming the challenge for some will be to use magnets that have less Dy and Tb but still manage to control temperature rise. This will lead to either an engineering challenge to adequately cool the generator or a materials science challenge to create a better magnet.

In order to take advantage of technologies that would enable comparable flux or thermal properties in a lower grade magnet, an R&D program to design a new generator would likely be required. Unfortunately, substitution of lower-temperature-grade magnets with comparable flux capability cannot easily be made into generators designed for use with a high-grade magnet. The cost of the R&D program is likely to be higher than the price difference seen by the spike in the higher temp and flux grade magnets.

Comparison of net present value (NPV) for an existing generator design with more expensive magnets vs. a new design with less expensive magnets would have to be undertaken. Ultimately, the lower-cost solution is likely to win, at least with some generator and wind turbine manufactures. Of course, other considerations might negate the desire to switch, such as the ability to fit the generator into the current turbine footprint or serviceability requirements.

Nevertheless, of the last 10 new wind turbines to be introduced which were based on a new architecture (i.e., as opposed to an upgrade to an existing platform design with a larger rotor, advanced controls, or a higher generator rating), 90% were based on PM based generators.

Ultimately, the question the industry needs to ask itself is, ‘Which innovations would lead to a design optimum point where one particular generator architecture would be favored above all others due to the ability to substitute whatever grade of magnet was most abundant, i.e., the lowest cost magnets?’

A brief look at the patent landscape for wind turbines as well as generators and motors and magnet manufacturing indicates that no one has solved this problem yet. As this future trend in wind turbine technology adoption continues, we all await the answer.

***

Philip Totaro is the Principal at Totaro & Associates, a consulting firm focused on innovation strategy, competitive intelligence, product development and patent search. You can find him at [email protected]