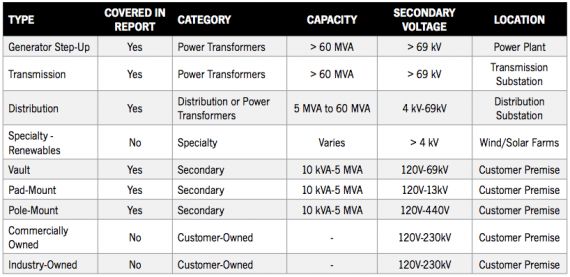

Following the release of GTM Research’s Transformer Monitoring Markets, 2013-2020: Technologies, Forecasts, and Leading Vendors report, a colleague and I hosted a webinar covering some of the key findings from the report. The report covers a full range of sensors, communications and applications that utilities across the U.S. are installing alongside their transformer infrastructure. GTM Research classifies utility-owned, liquid-filled transformers into three different categories, as shown in the following chart.

Source: Transformer Monitoring Markets, 2013-2020

By the end of the webinar, it had become clear that there was no way that we could address each of the 32 questions asked during the event's 10-minute Q&A session. To help address the questions that were left on the cutting-room floor that day, I have grouped them into three categories for the purposes of this article:

- Market Sizing and Growth Potential

- Pricing

- Features and Functionality

When questions were similar, they were combined, leaving us with a total of ten questions, five of which are presented here in part one of the article.

Market Sizing and Growth Potential

1. What are the assumptions of your forecast?

For individual assumptions and a detailed description of the methodology, there is no better source than the report itself, as the section devoted to market forecasts is 34 pages in length. However, I can describe some highlights of the forecast here. The forecast starts with a detailed discussion and analysis of the current utility-owned transformer stock in the U.S. The report takes those base numbers and then applies a forecast framework that is specific to each class of transformer through 2020.

With the stock and forecasted transformers determined, the forecast then applies sensor-specific assumptions to six sensor types:

- Transformer monitors

- Dissolved-gas analysis (DGA) monitors (further divided into single, multi-gas, and comprehensive)

- Resistive temperature devices (RTDs)

- Fiber optic temperature sensors

- Bushing monitors

- Secondary transformer monitors

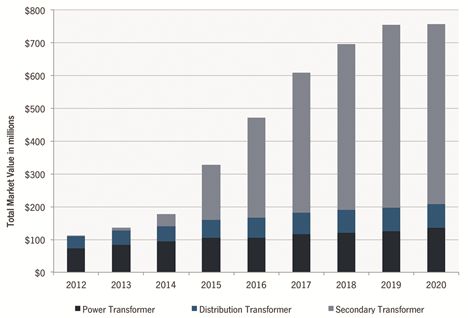

FIGURE: U.S. Transformer Monitoring Market from 2012-2020 by Transformer Type

Source: Transformer Monitoring Markets, 2013-2020

Forecasts for these products are split into the categories of retrofits and new transformer deployments. The first five equipment types are then further divided into demand for power and distribution transformers.

2. What are the timelines for the deployment of smart transformers? Is it too early?

This question was very common among attendees and is very relevant, but the answer has to go a bit deeper to have value. The first question that has to be answered is, what is a smart transformer?

A smart transformer has a variety of definitions, including a power or distribution transformer with communicating advanced digital relays with some asset management functionalities that provide support for cooling, load tap changer and protection of a transformer; a secondary transformer with loading, voltage and/or temperature sensors attached; a power or distribution transformer with a collection of monitors and conditions capabilities built in DGA, temperature, bushing monitoring, loading, and partial discharge sensors, etc.

To equipment manufacturers this distinction is paramount to guiding decision-making and identifying market opportunity and timing. However, to soft grid (software, automated diagnostics and analytics) vendors, the prevailing type of hardware may be less important, as they seek to control and manage the various data flows coming from the transformer ecosystem.

In order to shed some light on the question, I will break the definition of smart transformers into two subcategories:

- Smart Power or Distribution Transformer: A transformer with a transformer monitor and a combination of other sensor to have at least three different data sources

- Smart Secondary Transformers: A transformer with a secondary transformer monitor with voltage and loading

Smart power and distribution transformers are beginning to be deployed now at selected utilities (San Diego Gas and Electric, Arizona Public Service, Hydro One, and Southern California Edison), but for the most part utilities still are in the piloting stage with deploying diverse sensor systems. Vendor consolidation in the hardware space and continued development of software to acquire, manage and crunch asset condition data is beginning to push these technologies beyond concept, but for many utilities asset health will remain a tough sell. Regulatory focus will have to be brought to this area to push deployment.

Smart secondary transformers are also in the pilot phase, but are showing value at select group of utilities. The smart secondary market is quickly aligning with AMI deployments as the communications infrastructure implemented for AMI can be leveraged to lower the cost of implementation. Exceptions to this are developing to enable volt/VAR control measurements to more quickly and reliably reach the substation or control center. Recent partnerships and integration work are setting the stage for a major price reduction that will start to perk up this market in 2014, followed by a major growth year in 2015 when we expect more than 200,000 units to be sold. Long-term growth is expected to be robust, but some major threats are rising to the health of this market.

3. Why is full IT integration so far out? Are there opportunities in IT today?

Full IT integration promises more than the ability to acquire, manage and crunch data from a variety of utility sources such as: enterprise asset management, enterprise resource planning, data warehouses, operational data stores from the field to provide recommended maintenance and procurement actions; it also promises to connect this information to operations to allow operators the opportunity to adjust network configuration to optimize asset life. This has been and continues to be a bit of a pipe dream in the industry, as it combines a variety of smart grid capabilities (automated switching, demand side management, power limiting devices, storage, volt/VAR control, etc.) that are not deployed widely enough at any utility to enable, but it is the longer-term direction that utilities are heading.

Considering this vision requires integration at every step along the journey, there is ample opportunity to provide IT support and improvements throughout the process.

4. Why will the secondary monitoring market saturate at 10% deployment?

Frankly, it is because at least in the near and medium term, there is no need for these monitors to be on every transformer. The cost of these devices, coupled with many utilities’ opinion that secondary transformers are a commodity product that should be run to failure in the U.S., both lower the perceived value of monitoring. However, being able to leverage a collection of the five value streams (outage notification, revenue protection, asset management, volt/VAR control measurements, and power quality measurements) for secondary monitoring can justify implementation.

Most secondary transformers in the U.S. do not experience major power quality problems and are not connected to closed-loop volt/VAR control applications eliminating these value streams. Additionally, the virtual metering capabilities offered by Aclara, eMeter, GRIDiant, Itron and Oracle and being developed by Ecologic Analytics are reducing the need to monitor all transformers on the grid by providing a “good-enough” estimation of stress on these assets. Coupling these findings with the additional deployments of MV sensing devices, the total number of sensors that will likely be deployed at the secondary transformer decreases significantly, but the ability to target deployment at the location of distributed energy resources, troubled feeders or laterals, or at key voltage or reactive power junctions drastically improves the business case for the locations that these devices are deployed.

5. What is the opportunity for power transformers globally?

International opportunity is actually much stronger than in the United States. Key geographies for power transformer monitoring include China and the Middle East (namely, Saudi Arabia, Iraq, Kuwait and Qatar). Smaller markets such as Australia and New Zealand are also in the mix, but have far fewer customers and less money in the mix. China’s massive generation and transmission grid build-out is being accompanied by advanced monitoring on new transformers that make up what is by far the largest market in the world for DGA monitors.

Additionally, among higher GDP countries in the Middle East, increasing demand, desire for services and calls for higher reliability are allowing many giants such as ABB, Alstom and Siemens to put in advanced equipment with the construction of new infrastructure.

Stay tuned to Greentech Media this week for Part II of Ben's Transformer Monitoring Markets report Q&A. If you'd like to learn more about the market today, visit the report page at www.greentechmedia.com/research/report/transformer-monitoring-markets-2013-2020.