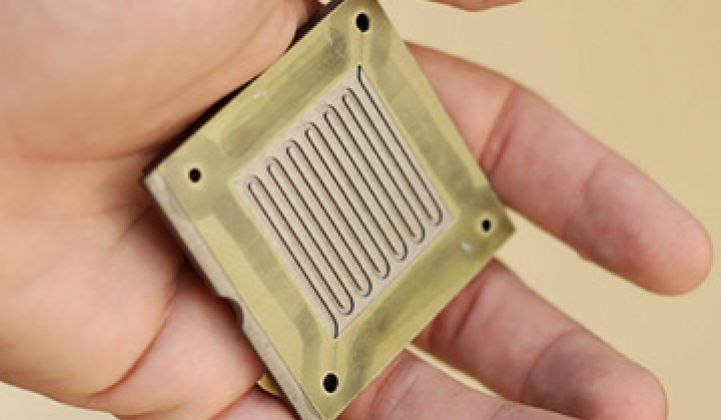

Fuel cells are in some ways the ultimate in energy technology. Liquids like methanol or gases such as methane or hydrogen are passed through a catalytic membrane to produce electricity and/or heat on the spot.

With one of these, large amounts of electricity can be produced on demand, instead of at a centralized power station. In Japan, Osaka Gas installs fuel cells in homes that convert 80 percent of the energy injected into them into household power and heat. The grid generally is only around 30 percent to 35 percent efficient due to transmission and conversion losses.

To top it off, fuels cells by their nature also store power and can circumvent the problems -- long charge times, weight, high prices -- associated with batteries. Oorja Protonics, a startup in Fremont, California, has created a fuel cell that provides all the energy a forklift will need for an eight-hour shift. A fill-up takes about five minutes. Traditional forklifts run on lead acid batteries, which take hours to charge and need to get swapped every four hours.

Some car makers still continue to research the possibility of cars powered by hydrogen fuel cells.

It’s too bad this dream technology is also one of the most finicky ideas ever devised. Catalytic membranes can require expensive materials such as platinum. Cracking and clogged membranes can also lead to high costs, unexpected maintenance and surly customers.

It’s no wonder that fuel cells have been the Next Big Thing since William Grove demonstrated the concept in 1838.

But will science and engineering come to the rescue? Companies like Bloom Energy and England’s Ceres Power say they have devised ways to boost reliability while dropping costs. Ceres in part relies on components from the diesel industry. Leasing and tax credits can lessen the sticker shock.

Is it a future whose time has finally come?

Read more on this topic in a joint effort by General Electric Ecomagination and Greentech Media, and join in on the conversation here.