There has been a lot of talk of late about the development of flexible third-generation thin-film solar technology, especially dye sensitized cells (DSCs). The question most people ask is: Where is the technology at today? Well surprise, surprise, it will become commercially available by the end of 2009.

The new kid on the block is U.K.-based G24i, which uses technology licensed by Konarka Technologies and Ecole Polytechnique Fédérale de Lausanne (EPFL). The company is a leading developer and supplier of DSCs, and just announced its first commercial shipment of its low-cost roll-to-roll produced DSC modules to, Mascotte Industrial Associates, a Hong Kong-based firm that makes bags and accessories for consumer electronics. Solar DSC-powered bags should become available in the marketplace during December, in time for the holiday season. This is the first of several commercial partnerships as G24i builds its manufacturing to mass production levels for several markets including consumer electronics (clothing and tents) and building-integrated photovoltaics (awnings and windows). Currently the company's manufacturing plant has a production capacity of 20 megawatts, which it will expand to 45-megawatt capacity during 2009/2010. Its flexible solar modules produce 0.5 watts power (>12 percent efficiency). Until now, G24i has been using dyes supplied by Dyesol Technologies.

I spoke with DSC's inventor Michael Gratzel, a chemistry professor at EPFL in Switzerland, after G24i announced that it had shipped the first commercial application of DSC. He said it was "one of the happiest days of his life, finally seeing endless [16] years of efforts and struggles coming to fruition."

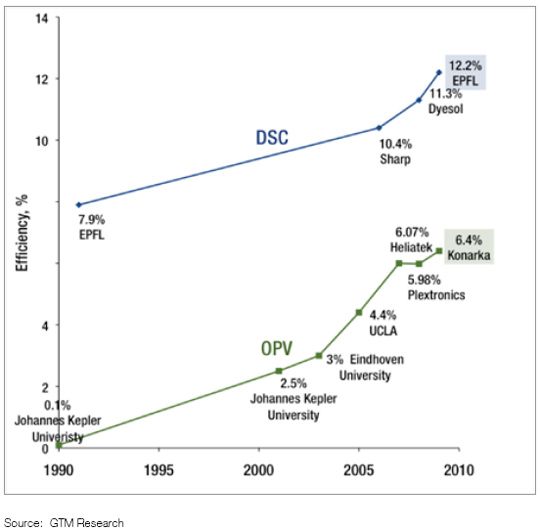

Another exciting development involves Dyesol Technologies. The leading Australian DSC material developer and supplier recently teamed up with Merck KGaA, which is a well-known German chemical giant with its foot placed firmly in the PV and printed electronics domains. Merck should be able to "iron out" the stability and decomposition issues associated with electrolytes by incorporating its novel ionic liquids into dye-sensitized cells, and also help speed up the commercialization process. On the sales front, Dyesol is working with Sigma-Aldrich – a global chemical material supply company – to make its range of DSC dyes and materials available to the many commercial and academic DSC developers in this emerging field. This only adds to Dyesol's ever-growing list of achievements both in terms of setting up a global manufacturing infrastructure (in the U.K., Italy, Turkey, Korea, U.S. and Taiwan), lining up commercial clients (notably G24i and Corus Colors) and enhancing cell performance, which is currently at more than 12 percent, with stability in excess of 20,000 hours. GTM Research and NREL believe that this technology is on course to reach module efficiencies in excess of 10 percent and stabilities of five years by 2012.

Efficiency Roadmap for Dye-Sensitized Solar Technologies (1990–2009)

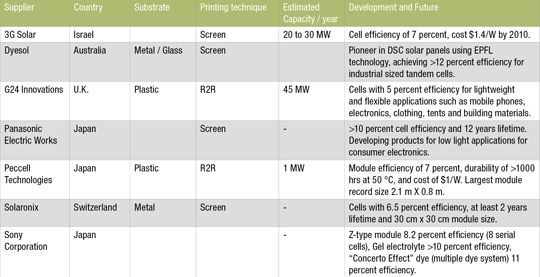

Dyesol is certainly covering all the bases. Other companies – such as 3G Solar, Pecell Technologies, Solaronix and SolarPrint – are expected to follow next year (see Selected DSC Developers below). It seems highly likely that DSC technology will be able to compete with other thin-film solar technologies such as amorphous silicon and cadmium telluride, especially if efficiency, cost and durability limitations continue to improve.

Selected DSC Developers

Many more commercial and technological developments are discussed in Philip Drachman's latest report from GTM research: Third-Gen Thin-Film Solar Technologies: Forecasting the Future of Dye-Sensitized and Organic PV.