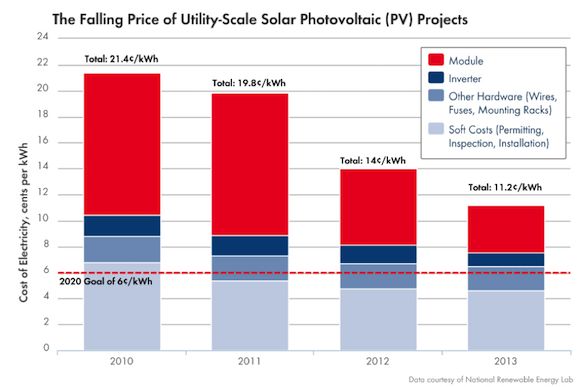

The cost of utility-scale PV has dropped over the last several years for a variety of reasons. Paramount among those factors has been the advancements made by PV equipment manufacturers in terms of product technology, production efficiencies and advances in integration. To further drive the solar industry’s growth, inverter suppliers, like module and balance-of-system manufacturers, must stay on pace with cost reductions to continue driving down the capital and operational expenses associated with large-scale solar development.

Inverter costs have decreased by as much as 70 percent over recent years, but additional savings can be achieved through a higher level of inverter integration. While the percentage of system costs represented by the inverter may remain similar, overall costs can be reduced by incorporating more functions within the inverter solution. A focus on value engineering takes into account not just the first costs of a central inverter, but also the long-term, operational costs of maintaining a highly productive PV plant.

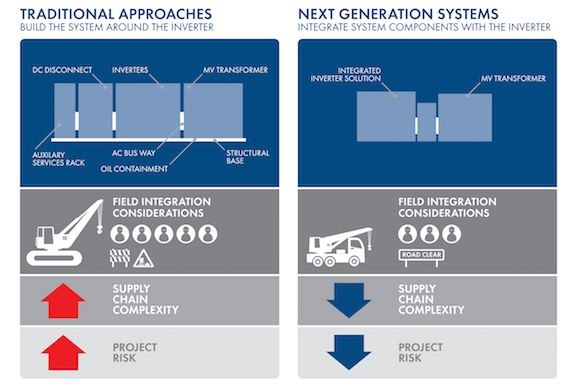

Achieving greater inverter cost reduction requires a shift in the way traditional central inverters are viewed. In the past, we approached the advancement of inverter integration in terms of the list of components that could be built around the inverter. This resulted in excessively large skid solutions where the level of “integration” was little more than logistical convenience.

In order to truly reduce system costs, we must redefine the way we approach integration by building the inverter around system needs. This means that the physical component we refer to as the inverter will now include advanced communication and control equipment; DC disconnects; a power auxiliary transformer; an MV transformer; switchgear; a tracker supply rack; an area for additional customer-specific equipment, and more.

Understanding the highly integrated nature of next-generation inverter solutions will assist PV plant stakeholders in more accurately evaluating potential vendors by helping them understand the true cost per watt of system solutions.

Inverter manufacturers recognize that a greater level of integration equates to a wealth of savings further down the project lifecycle. The more peripheral equipment that can be integrated into the inverter during the manufacturing process, the less field integration and associated costs will be incurred during the construction phases of the project, such as:

- Field labor cost is reduced due to less complex integration

- Transportation, crane and off-loading requirements are decreased because there is no massive skid to drop into place

- Vastly improved power density simplifies logistics and results in fewer units to transport, commission and maintain and fewer foundations to pour/equipment to set

- Civil work including road improvements (width for turning radius, etc.) is minimized

- Supply chain simplification and risk reduction are realized

Inverter manufacturers must also consider life-cycle cost reductions for ongoing operations and maintenance. Advancements in cooling technology are one way that long-term cost savings can be achieved. Intelligent precision air cooling technology integrated into the inverter cabinet has been field-proven to reduce service cost and mitigate the risk of inferior, outdated liquid cooling concepts. Precision air cooling systems are extremely effective even in the harshest of environments and can help drive down the cost of maintenance over the life of the PV power plant.

Additional advancements such as the inclusion of remote GFDI technology can have a profound impact on the reduction of field service calls. This proactive approach to detecting ground faults can be utilized on a regular basis to float the array from a remote location and detect insulation resistance throughout the system. The historical data that is gathered as a result becomes an invaluable tool for O&M providers seeking to reduce the operational expenses associated with frequent site visits due to ground faults.

So, moving forward, how do we continue the momentum of system cost reductions as a result of increased central inverter advancements? It is extremely important to collaborate with leaders throughout the PV industry to simplify and accelerate the field integration of the overall PV plant to achieve additional, system-wide savings. Through a mutual understanding of the challenges faced during the construction and operational life of a PV plant, inverter manufacturers can maintain the upward trend of fully integrated solutions while encouraging the downward trend of utility-scale PV costs.