Dissolving pencils in acid. That, roughly speaking, might be how cars get made in the future.

Rice University researchers have come up with a new way to produce graphene, a strong, lightweight form of carbon that can conduct electricity. Potentially, this could reduce the cost of mass producing composites that can substitute for metals in cars, planes, power lines and industrial equipment.

The green benefits are mostly indirect, but nonetheless real. Lightweight cars and planes go farther on a gallon of fuel than their heavier counterparts. Material science and design are the Third Fuel, equal in importance to batteries and biofuels, in the new transportation market. Composite production can also be less environmentally hazardous than traditional mining. Some also believe graphene could be used to produce cathodes or anodes in lithium ion batteries.

The researchers found that graphite, a form of carbon commonly used as the "lead" in pencils, will dissolve and unpeel into graphene sheets when dunked in chlorosulphonic acid. Early trials are yielding as much as two grams of graphene per liter of acid. Potentially, that indicates that mass production could become possible. The process yields pure graphene, not the less desirable graphene oxide.

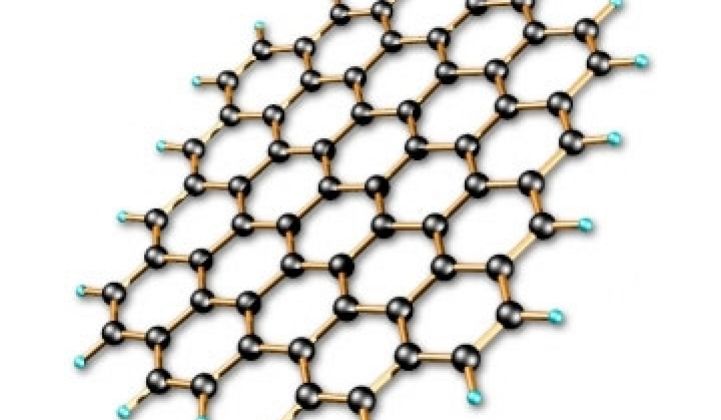

Graphite and graphene -- like diamonds and carbon nanotubes -- are both made from carbon. The difference lies in the arrangement of the atoms. Graphene is only one atom thick, whereas graphite has a more three-dimensional structure. As a result, graphene conducts electricity fairly efficiently because the electrons can't scatter easily. The bonds between carbon atoms are also particularly strong.

But, like carbon nanotubes, researchers have been stumped in how to take these magically delicious materials from the lab to the factory floor. Stand-alone sheets of graphene were only fully characterized in 2004. (Rice has been one of the primary centers for nano research for years.)

And speaking of industrial acids, Zeachem CEO Jim Imbler spoke to reporters before a groundbreaking ceremony for Zeachem's new 250,000-gallon plant in Oregon today. Zeachem started out as a cellulosic ethanol company with a biological/thermochemical process for converting eucalyptus or poplar trees into fuel.

Last year, the company began to expand into green chemistry. The first plant will be capable of producing acetic acid, ethyl acetate and ethanol.

"We see our platform more as a biorefinery," he said. The chemical output depends on the point at which you decide to stop processing the molecule.

Why the shift toward chemistry? Food-grade ethyl acetate can sell for $1 to $1.10 a pound, and there are seven pounds to a gallon. The market isn't as large -- the U.S. might consume only 400 million pounds of it a year compared to 140 billion gallons of liquid fuels -- but it pays well. Solazyme, LS9 and other biofuel companies have made a similar shift in recent years.

"Ethyl acetate takes half the equipment and sells for twice as much," he said. "You build less, spend less and make more."

Finally, in another chemistry-related story, plasma light maker Luxim has signed a deal with the Gerard Lighting Group that will lead to Luxim's light source being used in street lights in Australia. Luxim's bulb is about the size of a Tic Tac, but emits a tremendous amount of light. How does it work? Energy is pumped into the small, gas-filled chamber. The gas turns into a plasma and light emerges.

The company originally produced the bulb for big-screen projection TVs, but that market died. It now competes for commercial lighting contracts against LED companies. Topanga Technologies, which emerged out of stealth this year, competes with Luxim.