It's an air conditioner, but it works sort of like a loudspeaker.

Palo Alto Research Center (PARC) has launched an effort to replace the mechanical compressors in refrigerators and air conditioners with thermoacoustic compressors. More details will come out at the ARPA-E Energy Innovation Summit taking place this week in Washington, D.C.

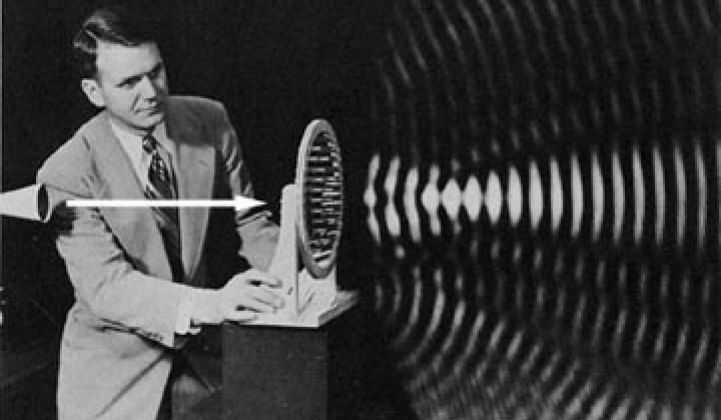

Thermoacoustic compressors essentially compress or expand gases with high-intensity sound waves. Compressing gases generates heat, while letting the gases expand cools things off. Think of the chill that gets created when a carbon dioxide cartridge is suddenly discharged and the gas is allowed to expand.

Mechanical compressors work on the same principle. Mechanical compressors, however, typically only achieve around 12 percent of the theoretical maximum. Thermoacoustic compressors can triple and more that efficiency rating because of the inherent properties of sound waves. A thermoacoustic compressor can potentially complete 10,000 cycles a second, according to Scott Elrod, vice president of the hardware systems laboratory and head of PARC's green tech efforts.

"You can do the same thing with a sound wave, but with more successive compression and expansion cycles," said Elrod. "It would look pretty much like a speaker but with high intensity sound waves."

Thermoacoustic compressors are employed in labs to turn atmospheric gases like nitrogen into extremely chilly liquids. However, that equipment works best in extreme situations and is not particularly efficient or economical for keeping office buildings at 72 degrees. PARC's breakthrough lay in devising a thermoacoustic device for ambient temperatures.

If it works and can go commercial, the cooling sound from PARC could take a substantial chunk of out U.S. and even global power consumption. Cooling-refrigeration and air conditioning-account or 17 percent of the energy consumed in commercial buildings and 20 percent in residences, according to the 2008 Buildings Energy Data Book Buildings from the Department of Energy. Buildings account for 39 percent of total U.S. energy consumption and 76 percent of the electrical consumption.

If widely deployed in the U.S., the technology could reduce energy consumption for cooling from 7 BTUS to 4 BTUs, which translates to a 13 percent reduction of electricity consumption in the U.S., according to PARC.

Air conditioning may not be as groovy as electric cars or even solar, but the field has begun to attract entrepreneurs and investors. Ice Energy, which makes thermal mass (i.e., ice) powered air conditioners, has raised nearly $75 million since 2002. The company is currently trying to convince utilities to cover the cost of swapping out existing, inefficient air conditioners in certain regions with their units: Ice Energy's Ice Bear units make the ice at night and therefore curb peak power consumption.

Other companies to track: Chromasun (solar-powered air conditioner company founded by Ausra co-founder Peter Le Lievre), Calmac (producer of large-scale ice air conditioners), Coolerado (a novel system that extracts heat with mist via the Maisotsenko Cycle), Optimum Energy (software for optimizing air conditioner chiller performance) and anyone with desiccant coolers (a gel that shifts from solid to vapor to eliminate heat). In some cities like San Francisco and Seattle, architects are also exploiting passive, ambient cooling and leaving out the AC unit entirely in new buildings. Last week we met with EcoThermics, which says it can generate hot and cold air from compressing and releasing carbon dioxide. It developed the unit for the U.S. Army after the E.U. passed regulations mandating that NAT and other organizations eliminate air conditioners based around questionable chemical refrigerants. See Eleven Cool Names and Concepts to Watch In Air Conditioning for more.

PARC has created computerized simulations and a basic prototype. Two prototypes coming in the relatively near future will hopefully validate the simulations.

How do they work? Gases are inserted into a tube filled with mesh membranes called regenerators. As the sound wave passes through the regenerators, a low-pressure, low-temperature/high-pressure, high-temperature gradient begins to form. One end gets hot while the other gets cool. Heat exchangers can then be used to extract and exploit the heat or cooling power.

Like some other green projects at PARC, the thermoacoustic coupler can be traced back to printers and copiers. (This place used to be Xerox's internal lab before it got spun out as an independent subsidiary in 2002. It's where the PC was invented.) PARC had once conducted research on exploiting sound waves to focus ink-jet droplets, said Elrod. The idea was to develop photo quality imaging. Although promising, Xerox did not commercialize the technology.

Research on controlling toner powder has lead to a spiral that could one day be used in water purification or separating algae from water to make biofuel.