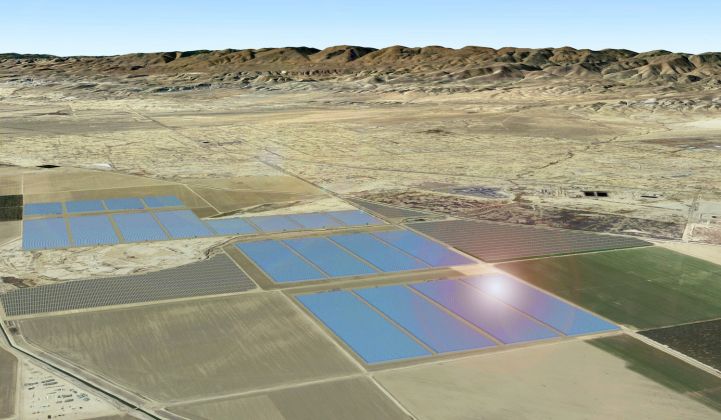

A newly announced project at California’s Belridge oil field will bring solar and fossil fuels together at one of the state’s biggest solar deployments.

The partnership, between Belridge field operator Aera Energy and solar thermal power company GlassPoint, will feature a 26.5-megawatt photovoltaic array and 850 megawatts-thermal of solar collectors for steam generation. It's slated to come on-line in 2020.

Aera, which is jointly owned by majors Shell and Exxon, produces almost a quarter of California’s oil and gas. GlassPoint currently has two running projects in Oman that are tied to oil extraction operations.

Aera monitored GlassPoint for years after attending the 2011 launch of a pilot plant at the Berry Petroleum Company field, also in Kern County. But GlassPoint’s COO and acting CEO, Ben Bierman, said “the stars aligned” only recently to make a project viable for Aera.

“At first it didn’t make economic sense to deploy solar at our operations,” said Aera CEO Christina Sistrunk, in an email. “But over the years GlassPoint has made advancements in their technology to reduce costs and has proven the viability of their solar technology in Oman.”

When water is separated from oil in the extraction process, GlassPoint’s thermal enhanced oil recovery (EOR) system turns it into steam using curved mirrors inside greenhouse-like structures. The high-pressure steam is pushed back into the earth to help pump more oil.

Oil producers invented thermal EOR in Kern County in the 1960s to release “heavy oil” from wells that could no longer produce. Oil from the fields originally powered the boilers. Natural gas became the fuel of choice in the 1980s. Now GlassPoint’s model clears the way for extraction companies to integrate renewables instead.

A recent analysis found that solar steam generators are often lower-cost than natural-gas generators, when gas costs $6 mmbtu.

“Our company is maniacally driven to reduce the cost of solar thermal energy,” said Bierman. “This analysis by Aera shows other producers in the Valley that the economics must work.”

GlassPoint uses greenhouses to protect its mirrors from wind and other elements, allowing the company to cut down on mirror material by 18 percent. A washing robot cleans the glass every night to restore performance. The company also reduced the weight of the structure that supports the mirrors by 30 percent and reduced the number of motors it uses by a third -- all in the name of cost-cutting.

Now that Aera is on board, GlassPoint is eyeing other producers in the Valley and beyond. Most active thermal EOR fields are in the Middle East (where GlassPoint has two projects) and California. But as costs continue to decline, the technology will likely become viable in countries such as India, Indonesia and China, according to Bierman.

As more countries introduce carbon-reduction targets, solar systems will likely entice more producers. Sistrunk said California’s extension of its cap-and-trade law in July provided the regulatory and political stability to ensure investments in emissions reductions would still make economic sense in the coming decades.

Thermal EOR uses 1.7 trillion cubic feet of natural gas a year to produce steam. Every year the Belridge project will offset 376,000 tons of carbon dioxide, equal to 80,000 cars. The site's solar PV installation will help power equipment and building operations.

“We’ve had something of a false dichotomy for the last decade, where it was envisioned as some kind of competition between renewable energy and conventional energy forces,” said Bierman. “We see this as an energy convergence.”