Oxford PV is claiming a new efficiency record, as it moves to create a 30+ percent efficient solar cell by 2020.

The U.K. renewables technology developer hit a 27.3 percent conversion efficiency with a tandem solar cell using a material that experts believe could transform the solar sector.

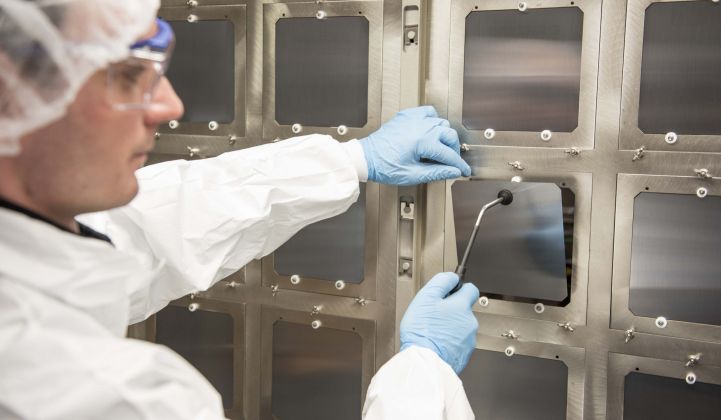

The company’s 1 cm2 perovskite-silicon tandem solar cell efficiency was certified by the Fraunhofer Institute for Solar Energy Systems, said Oxford PV in a press release.

The efficiency was more than half a percentage point over the previous efficiency world record for a single-junction silicon solar cell, which stands at 26.7 percent, according to Oxford PV.

The theoretical maximum for single-junction, direct bandgap PV, as determined by the Shockley-Queisser limit, is about 33 percent. For indirect bandgap materials such as silicon, this theoretical maximum is 29 percent, according to Frank Averdung, Oxford PV’s CEO.

In practice, though, commercial silicon cells will struggle to rise above 25 percent.

The most efficient single-junction direct bandgap solar cell developed so far is made from crystalline gallium arsenide and achieved an efficiency of 28.8 percent.

Single-junction, direct bandgap perovskite cell efficiencies would also be capped by the 33 percent Shockley-Queisser limit, but Oxford PV is not concerned about pushing the material to that level of efficiency just yet.

Instead it hopes to breach the 30 percent efficiency mark by combining perovskite with the best silicon technologies on the market today. Such a tandem arrangement is the one used in Oxford PV’s new record-breaking cell.

The concept involves coating a traditional silicon cell with a thin layer of transparent perovskite. The silicon and perovskite are tuned to different wavelengths.

When light strikes the cell, the perovskite absorbs as much energy as possible from the blue end of the spectrum. The rest of the light passes through the perovskite onto the silicon, which absorbs energy from the red end of the spectrum.

In an ideal setup, there would be no overlap between the perovskite and silicon bandgaps, meaning the total efficiency of the cell would be the sum of the efficiencies of each layer.

In the real world, a degree of bandgap overlap means the bottom layer of a tandem cell is usually only about half as efficient as it would be if it were exposed directly to sunlight. This is enough to make a big difference to the overall efficiency, however.

Oxford PV’s record-breaking cell, for instance, consisted of a 17 percent efficient perovskite layer and a 22 percent efficient silicon foundation, reduced to 11 percent because of the bandgap overlap effect.

The sum of these efficiencies, at just under 28 percent, is still a major advance over single bandgap silicon on its own. Oxford PV is looking to sell the tandem concept to major solar cell manufacturers rather than developing higher-efficiency, perovskite-only cells.

That’s because, Averdung said, “it is extremely difficult to introduce a completely new material into the market.”

Attempts to compete with silicon supported a whole generation of copper indium gallium selenide (CIGS) thin-film solar makers between 2011 and 2015, Averdung noted.

“You could absolutely have perovskite solar cells and theoretically go beyond the 30 percent barrier,” he said. “But in reality, we need to play with the market. We add a capability that makes their solar cells better. This is an upgrade path to an existing product.”

Oxford PV expects to be able to add an extra percentage point of efficiency a year to its perovskite product, up to 30 percent, said Averdung. After that, efficiency gains would likely slow to around half a percentage point a year, he said.

The challenge for now, he said, is not to make the material more efficient but to make it more stable. Early perovskite compounds, made of methylammonium lead iodide chloride, tended to deteriorate rapidly under humidity.

Oxford PV now has a proprietary composition that can last for several weeks, long enough to be transported to a manufacturing plant and encapsulated with an insulating layer.

The composition can also withstand temperatures of up to 200º C, so it can endure manufacturing processes and extreme environmental conditions.

The company is aiming to road-test a tandem cell in the field next year and hopes to have products on the market by 2020, Averdung said.