When microinverters and optimizers first entered the market, their value propositions were largely similar: increased energy harvest, lower risk from module-level data, and improved safety. However, as module-level power electronics (MLPE) suppliers grew more sophisticated, their value proposition changed: Microinverters focused on design simplicity, DC optimizers focused on reducing cost at the inverter and electrical BOS, and all technologies found that they enabled larger systems, increasing profit for everyone in the value chain. According to GTM Research's newest solar report, the MLPE segment is riding these four benefits to strong growth -- and in the process, it is changing the way solar systems are designed and installed.

Design Simplicity

Because microinverters operate independently, they are inherently simple to design. Anyone trained in basic layout rules can lay out a rooftop with microinverters. This leads to a number of different benefits, including:

- Lower skill needed to design a solar array. For installers new to solar, system design is a challenge. With microinverters, the magnitude of that challenge drops significantly. There are no strings to size and no major penalties for arrays that are not designed well.

- Lower-cost designers. Since designing with microinverters takes less skill, a company can use lower-cost labor for system design, reducing overhead.

- Improved inventory management. Residential installers can encounter systems that can range from 2 kilowatts to 20 kilowatts. Microinverters can address all of these systems with a single SKU -- making inventory management easier, particularly for smaller, lower-volume installers.

- Fewer change orders. If an installation team finds an unexpected obstruction on a roof, this could result in a significant system redesign for a traditional architecture. A microinverter system can be redesigned on the fly, greatly improving installation velocity.

Because these are business-model-level changes, the customers who adopt microinverters tend to be very loyal.

Design Flexibility: Expanding System Size

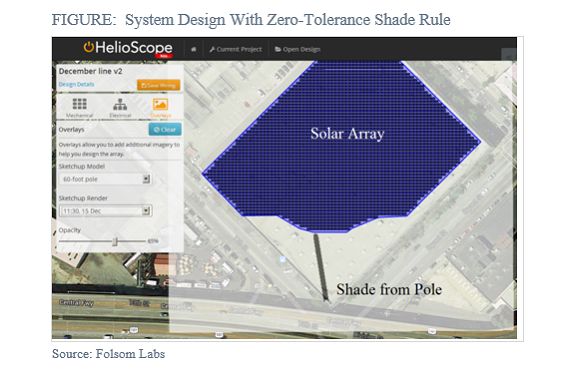

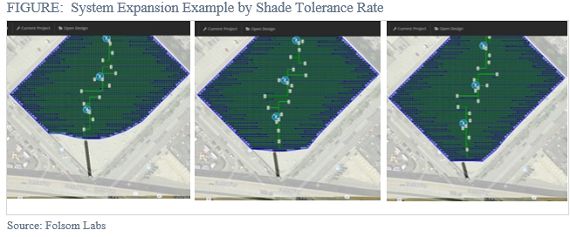

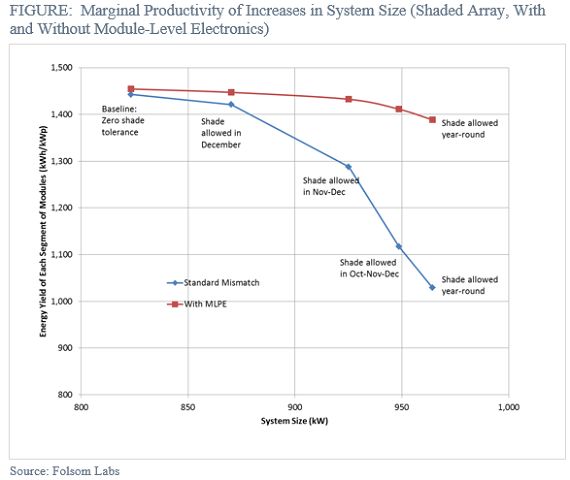

With MLPE, system designers can more aggressively design near shade, resulting in larger and more profitable systems. On a typical commercial rooftop, a single power pole could reduce the system size by 17 percent. With MLPE, these shaded modules can be added back.

Module-level optimization enables marginal modules to produce more energy and therefore become more economically viable, as the following chart indicates.

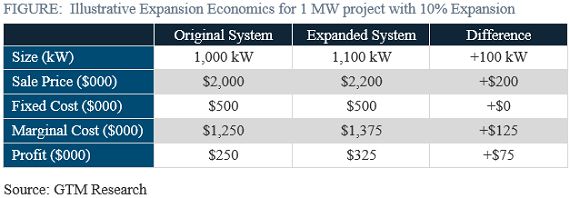

A larger system is more profitable, since fixed costs can be amortized over a larger project. As an example, consider a 1-megawatt project that can be expanded by 10 percent.

The 10 percent increase in system size increases the project profit by $75,000, or $0.075 per watt. Besides increasing developer profit, this benefit also increases the number of modules used on a project -- making the module manufacturers happy.

Improved Inverter Design and Reduced Cost

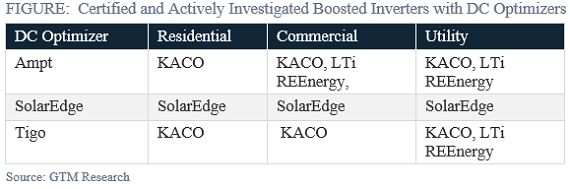

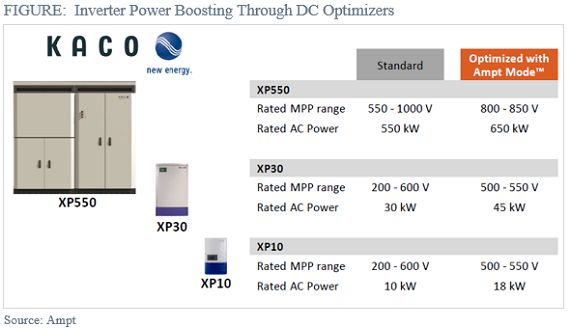

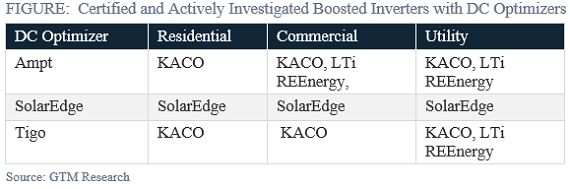

When paired with DC optimizers, inverters can be redesigned for cost and efficiency improvements. When optimizers can provide inverters with a constant voltage, there are two benefits: the voltage boost stage can be eliminated (thus reducing cost and increasing efficiency), and the inverter can handle more power (because the components can be run closer to their maximum power). Joint-certified products have shown a 10 percent to 80 percent boost in nameplate rating.

Reduction of Electrical Balance of Systems and Associated Labor

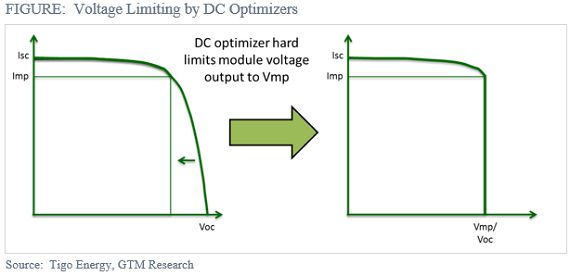

DC optimizers can also reduce the conductor quantities needed in solar arrays. Optimizers limit the module’s max voltage to the Vmp, enabling system designers to connect more modules in series. Module strings can be “stretched” by 30 percent to 50 percent, which results in fewer DC combiner boxes and less DC wiring and labor.

As a result, optimizers can save 30 percent to 40 percent of electrical balance-of-system and electrical labor costs. The DC electrical costs vary significantly based on the size and location of the array, with total costs anywhere from $0.10 to $0.25, so the value of reducing these costs can be anywhere from $0.03 to $0.10 per watt.

While energy harvest from module-level optimization is important, there are a number of other factors that are driving significant value for these products. As the market learns how to deploy these design innovations, the opportunity for this segment will grow even further.

***

For more on GTM Research's new report, The Microinverter and DC Optimizer Landscape 2014, click here.