What happens when a module fails in a 1-megawatt photovoltaic system, bringing down a 3-kilowatt string?

If the monitoring system tracks production for each of the two 500-kilowatt inverters, the loss of output will only represent 0.6 percent of a 500-kilowatt array’s capacity -- virtually impossible to detect, especially when pyranometers commonly used in utility-scale PV plants measure solar irradiance with a +/- 2 percent uncertainty (or more). Even comparing the output of both inverters would hardly allow detection of the fault: inverters measure power output with a relatively high uncertainty (typically +/- 1 percent to +/- 5 percent).

Arguably, even multiple string failures could go unnoticed until the next inspection when maintenance technicians perform systematic string testing.

In order to quickly detect such failures and minimize the associated energy losses, some PV plants are equipped with string monitoring equipment. This consists of "smart combiners" collecting current (and sometimes voltage) for a string or a small group of strings, and sending this data to the monitoring system where some software analyzes the information and identifies low production string conditions.

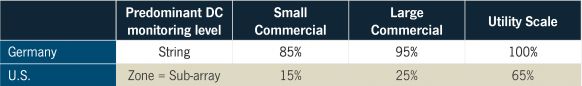

String monitoring is a common practice in most European markets, along with string inverter designs for PV systems, which intrinsically provide the ability to monitor at the string level, since each inverter is a string or a small group of strings. In a recently published report about global PV monitoring markets, GTM Research and SoliChamba Consulting estimated that 100 percent of new utility-scale PV plants in Germany in 2012 were string-monitored, along with 95 percent of large commercial systems and 85 percent of small commercial ones (including plants with string inverters).

In other parts of the world like the U.S. and Japan, however, very few PV plants are string-monitored, even in the utility-scale segment. In those markets, the dominant perception is that string monitoring significantly increases the initial cost of the PV system without providing enough yield increase to justify such investment. No independent study has either proved or disproved this theory, and opinions may vary between EPC firms and project developers.

String and Sub-Array Monitoring Adoption Rates by Segment, 2012

Source: GTM Research and SoliChamba Consulting

In order to better understand the logic behind this different approach, let’s examine the economics of a broken 3-kilowatt string. Assuming that the average annual yield is 1,500 kWh/kWp and the faulty string goes undetected for six months (until the next inspection), the lost production would amount to 2,250 kilowatt-hours. For a 2006-built German plant benefiting from the 40 euro cents feed-in tariff, this would represent a $1,200 loss. For a 1-megawatt system, the additional cost of string monitoring equipment ranges from $10,000 to $15,000, which is the equivalent of $500 to $750 annually over a twenty-year time span (excluding financing costs and installation, which is usually part of overall EPC budget). In these conditions, an average of one string failure per year would justify the investment. For a U.S. plant with a PPA price of 10 cents, however, the same production loss would only be worth $225, so it would take two to four annual string failures on the same 1-megawatt array to justify the investment. This simple calculation goes a long way toward explaining the gap in string monitoring adoption rates between Germany and the U.S.

In the past few years, a new DC array monitoring practice emerged in America, referred to as "zone monitoring" or "sub-array monitoring."

By collecting sub-array data from the master combiner, zone monitoring provides an intermediate level of granularity for issue detection and diagnostics, at a much lower upfront cost than string monitoring ($3,500 to $5,000 for a 1-megawatt plant). With this approach, the ability to detect subtle issues is more limited, and the guilty string cannot be specifically identified -- it is only possible to single out the sub-array that is underperforming because of it. In the case of our previous example, if each 500-kilowatt master combiner includes 15 sub-arrays (for a 33-kilowatt individual capacity), the loss of a 3-kilowatt string represents a 10 percent reduction of the affected sub-array’s capacity -- an easily detectable anomaly. The annualized cost of $175 to $250 for zone monitoring only requires one string failure per year to pay for itself in a 10-cent PPA scenario. No wonder zone monitoring has become the predominant DC monitoring method in the U.S., with string monitoring being deployed in a small fraction of American plants (even large-scale ones). GTM Research and SoliChamba Consulting estimate the adoption of DC monitoring in the U.S. in 2012 at 65% in the utility-scale segment, 25 percent in the large commercial segment, and 15 percent in small commercial. Most of it is believed to be zone monitoring.

Looking forward, with feed-in tariff levels in Germany and most European markets at lower levels than ever, the financial benefits of string monitoring are less compelling than they once were. At the going feed-in tariff rate in Germany of 10 euro cents for new ground-mount plants, our 3-kilowatt string now causes $300 of lost revenue over six months. Of course, the economic equation is incomplete without a good understanding of actual string failure rates -- a critical piece of information for which no reference data currently exists. And as a result, the jury is still out concerning the actual return on investment of string monitoring and zone monitoring systems.

As often in the solar world, the ultimate decision to adopt a technology lies in the hands of the investors and their technical advisors. In Europe, these firms often mandate string monitoring for large-scale plants, and will consider a PV system less valuable if it does not include such monitoring capability. In the U.S., few solar investors have a strong opinion on this topic, and independent engineering firms that validate the production estimates used in financial calculations do not consider any difference in output whether a plant is a monitored at the inverter, sub-array or string level. In such circumstances, project developers and EPC firms are unlikely to invest in string monitoring technology.

Over time, as more data becomes available about module and string failure rates, we can expect the choice of monitoring approach to become less cultural and more financial.

For more information on global PV monitoring markets, including additional data on adoption rates of DC monitoring in various countries, projected monitoring market size and competitive landscape by country and segment, learn more about our new report, Global PV Monitoring: Technologies, Markets and Leading Players, 2013-2017.