Last week was the 132nd birthday of the light bulb. On October 21,1879, Thomas Edison devised a workable electric light at his laboratory in Menlo Park, N.J.

This week, Bridgelux closed an additional $15 million to accelerate research and development of the firm's gallium nitride-on-silicon LED chip technologies. Funding came from VantagePoint Capital Partners, DCM, El Dorado Ventures, Novus Energy Partners, IFA, Chrysalix, Harris & Harris Group, Craton Equity Partners, Jebsen Asset Management, and Passport Capital, et al. Bridgelux is going after the lighting industry.

Building a solid state lighting (SSL) firm turns out to be expensive -- Bridgelux is at the $200-million-of-VC-invested mark. Other SSL firms such as Luminus Devices have also been less than capital efficient.

But going after $100 billion markets is not for the weak of heart -- or wallet.

According to the Bridgelux CEO, Bill Watkins, the firm generated $32 million in revenue last year and will hit $80 million this year. This week's funding tranche is directed at making a specific shift in technology: moving from four-inch sapphire substrates to eight-inch silicon substrates.

Alan Salzman of VantagePoint Venture Partners, an investor in Bridgleux as well as LED bulb firm Switch, has told Greentech Media that he sees a transformation occurring in lighting, with everything switching out to solid state lighting and causing "a $100 billion industry to flip." In Salzman's view, the mammoth lighting incumbents like Philips, GE and Osram "might catch up -- or might not."

Factors holding back LED lighting for general illumination include light quality and cost -- light bulbs show tremendous price elasticity. But LED light pricing is dropping fast. And light quality continues to improve.

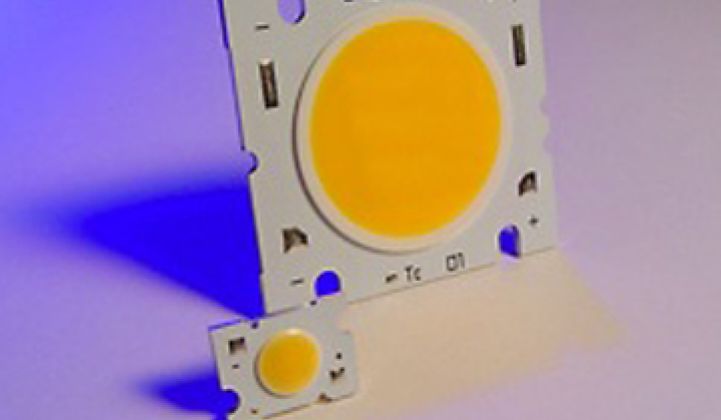

Innovation is happening up and down the value chain from chips and light engines at Bridgelux to bulbs like Switch or Lemnis to networked lighting like Redwood Systems, Adura, and Digital Lumens.

Silicon LEDs could cut the cost of solid state lighting since LED chips account for more than half the cost of a bulb. Manufacturers have tried to grow LEDs on silicon for years with mixed success.

"This is the holy grail. This is why all of the big semi guys like Samsung, LG and Toshiba are looking at LEDs," Watkins told us earlier this year. The Bridgelux breakthrough is possible because of a proprietary buffer layer. Samsung uses an AlN buffer layer with graded AlGaN along with SiN to decouple stress between the Si surface and GaN layer.

Silicon wafers are far cheaper than sapphire or silicon carbide and sport thousands of fabrication facilities around the world. Silicon LEDs could cost pennies per unit instead of $0.35 per chip and could make the cost of LED bulbs a no-brainer decision for consumers.

The technology to make silicon substrate LEDs exists. Scaling remains the challenge.