Getting an entirely new and novel battery chemistry to commercial scale is Sisyphean work. And Ambri, with its liquid metal battery technology, has just hit a large speed bump on its uphill climb to grid-scale energy storage domination.

CEO Phil Giudice sent out an update today reporting, "Unfortunately, we have not made the technology progress we had anticipated. As a result, we will not be delivering commercial prototype systems later this year or early next, as we had originally planned. Consequently, we have reduced our team by 14 colleagues." That's approximately 25 percent of the staff.

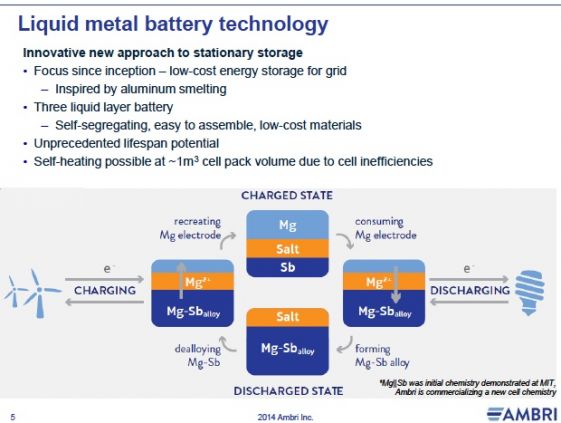

Ambri is a battery firm based on the research of Donald Sadoway, MIT professor of materials chemistry, and inspired by the economies of scale facilitated by modern electrometallurgy and the aluminum smelter. The big-battery startup has raised more than $50 million in venture capital from investors KLP Enterprises, the family office of Karen Pritzker and Michael Vlock, Building Insurance Bern, Khosla Ventures, Bill Gates and French energy giant Total, along with plenty of MIT and government grant money.

The CEO continued, "Our reduction in staff and slowed commercialization path will provide us more time to solve the engineering challenges ahead of us before we re-engage in committing to commercial deployment schedules. Specifically, we are acutely focused on developing a robust high-temperature seal for our liquid metal battery. Our primary design of this component demonstrated promising results last fall and this spring, but did not perform sufficiently well under rigorous verification testing protocols which we ran this summer. We are now pursuing other seal designs that show initial promise, but it will take more time to confirm their viability."

We spoke with the CEO today. He emphasized that "the basic science that's been demonstrated continues to look phenomenal, with an extremely low fade rate." According to the company, "Cells have cycled thousands of times in in-house tests with negligible fade on full depth of discharge cycling, extrapolating that after 10,000 charge/discharge cycles the batteries will retain 98 percent capacity availability."

The CEO added, "It's not a reset." He said that the company's investors are still all in and that there is two years' worth of capital on hand.

According to his update, "Ambri’s board and investors share our disappointment that progress has not happened more quickly or easily, but fully understand the accomplishments we have achieved, the challenges we face and Ambri‘s potential. The market opportunity for grid-scale energy storage is large, growing and global. Bringing new scientific discoveries in the physical sciences to commercial success is hard; the process is not entirely knowable or amenable to predictable timelines."

***

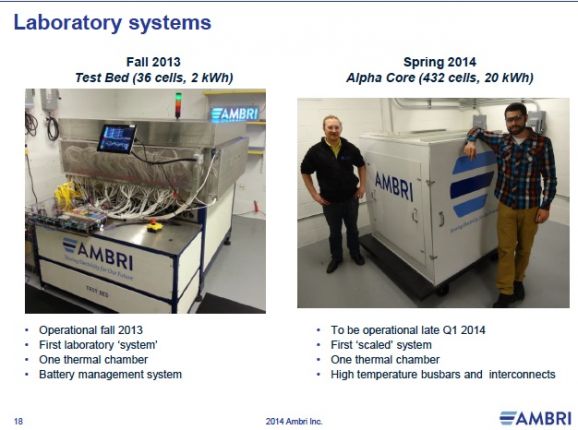

In March of last year, we reported on a presentation given by Ambri's David Bradwell at Infocast's Energy Storage Week. Here it is.

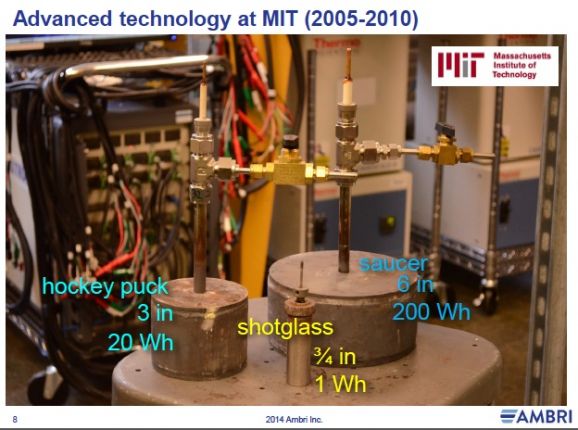

Prototype units started as the "shot glass," followed by the 3-inch, 20-watt-hour "hockey puck," and then by the 6-inch, 200-watt-hour "saucer." The commercialized product will use a 6-inch square.

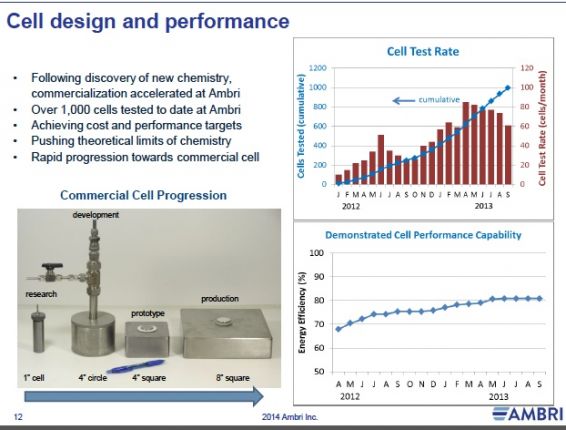

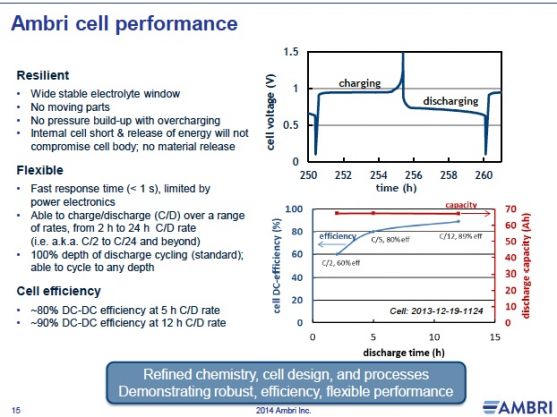

Bradwell notes that the batteries achieve 1,000 cycles of continuous deep cycling with negligible fade. There are no moving parts, pumps or valves in the design.

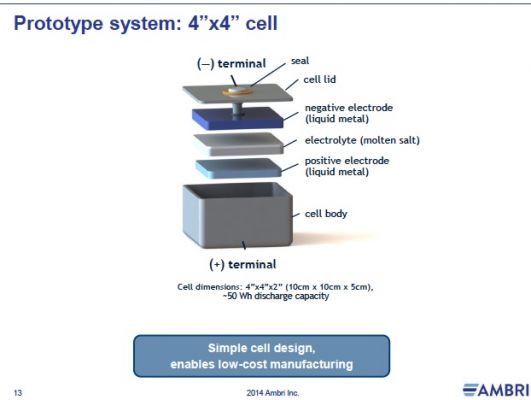

The cell is contained in a 4-inch-by-4-inch stamped stainless steel housing with no nanoscale microstructures or difficult-to-synthesize materials, according to the co-founder.

The cells have a DC-to-DC efficiency of 80 percent at a five-hour charge/discharge rate and an AC-to-AC efficiency of 70 percent to 75 percent.

Bradwell noted that all manufacturing processes and robotic cell assembly had to be developed by Ambri. He claims that the technology has a lower manufacturing cost and lower employee-per-square-foot-of-factory ratio than that of lithium-ion battery technology. The CTO also suggested that Ambri's pricing will fall between that of pumped hydro and compressed-air energy storage.

MIT's Don Sadoway on Ambri technology