In the future, your car could be built with viruses.

Scientists at MIT have concocted a lithium-ion battery in which the cathode and the anode, the positive and negative electrodes that swap charges, were partly put together by genetically modified viruses. It works as follows. The viruses are genetically engineered to secrete specific proteins. In turn, these proteins react to other chemicals in their environment to form structures.

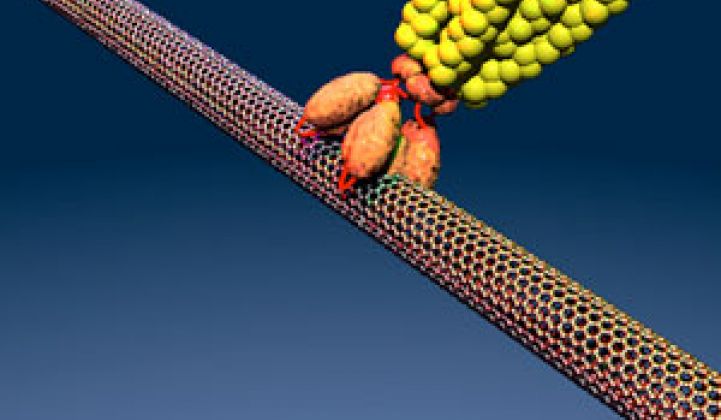

For the cathode, the viruses were able to first attract and bind iron phosphate and then carbon nanotubes to create a network of conductive material. For the anode, the viruses attracted cobalt oxide and then gold particles to form a nanowire. The anode was developed three years ago, but the cathode and whole battery is new. Building the cathode was more difficult because cathodes need to conduct electricity rapidly. The carbon nanotubes, which conduct electricity faster than metals, help in this regard.

The prototype battery is a coin battery, but conceivably cell and larger batteries for powering cars could be made from this process. Right now, it can go at least 100 charges before performance tapers off, but that number will increase.

The idea behind industrial bioengineering is that viruses, bacteria and other microorganisms are really microscopic chemical factories. They eat, and through the metabolic process, subsequently secrete things. Wine, cheese, beer and antibiotics are, in that light, really the waste product of selectively fed and bred microbes. Microbes also work in dank environments, can be produced en masse and disposed of after a long work week. Try doing that to your new college hires.

Various green companies are tinkering with ways to use bugs on the factory floor as a way to replace energy-intensive processes (like cooking chemicals at high temperatures to produce other compounds) or noxious, fossil fuel based substances. Genomatica, for instance, has devised organisms that can produce chemicals like methyl ethyl ketone (see Genomatica: Microbe-Made Chemicals Could Save Empty Ethanol Plants). Several companies want to make ethanol or synthetic petroleum from bugs. More often than not, these researchers use genetically modified forms of e coli because its genome and ways to modify it are well understood. Many call it the workhorse of biotech.

The leader on the project is Angela Belcher, the Germeshausen Professor of Materials Science and Engineering and Biological Engineering. Belcher has been one of the leading scientists in exploring ways to exploit microbes and been the recipient of several awards. Some of her work has included devising organisms that secrete chemicals that can help bind insulating layers inside semiconductors or organisms that can detect weak points and stress lines in things like airplane wings. Cambrios Technologies was spun out a few years ago to commercialize some of her inventions. (She got into the field by wondering why abalones can produce hard shells out of what is essentially chalk.)

Others working on the battery include professor Gerbrand Ceder and graduate students Yun Jung Lee and Hyunjung Yi. Those two were the lead authors on a paper published in Science on the battery.

When will cars rely on virus batteries? It could take time. Scaling microorganism production will take time and quite a bit of testing. Carbon nanotube production will also have to be improved. Now, nanotubes are often bought by the gram.

The team will also look at ways of developing lithium batteries with slightly different cathode chemistries which could be capable of storing more power.