Stealthy ethanol startup Coskata has signed a partnership deal with automaker General Motors, the companies announced Sunday at the North American International Auto Show in Detroit.

GM is taking an undisclosed equity stake in Warrenville, Ill.-based Coskata, as part of the startup's Series B round, which CEO Bill Roe said is nearly complete. Coskata was founded with a $10 million Series A round, in July of 2006, from Khosla Ventures, Advanced Technology Ventures and GreatPoint Ventures.

As part of the deal, Coskata and GM also are pairing up on research and development, commercializing Coskata's fuel and investigating the possibility of making ethanol from GM facilities' waste and unrecyclable vehicle parts.

And GM will use Coskata's fuel to test vehicles at GM's Milford Proving Grounds. The startup is expected to begin delivering its fuel to GM from its first pilot plant -- a 40,000-gallon-per-year facility -- in the fourth quarter of this year.

At an invitation-only press briefing at Coskata's offices last week, Mary Beth Stanek, director of environment and energy policy and commercialization at GM, said the vehicle manufacturer was not taking a controlling stake in Coskata, but would be "a significant investor."

"We want strong alignment with this company," she said. "We benefit if fuel pricing is low, because customers will want the vehicle that can use that fuel."

While GM still is considering partnerships with other cellulosic-ethanol companies, "we are not uniformly placing bets or peanut-buttering this," she said. "We're looking for leaders and we're really excited about this."

The announcement kicks off the press preview for the North American International Auto Show in Detroit, which opens publicly Jan. 19.

Founded in 2006, Coskata says its thermochemical technology to make ethanol from nonfood sources will be able to produce the fuel for less than $1 per gallon, giving it the ability to deliver prices 50 cents to $1 lower than gasoline at the pump.

The company expects to be able to reach those costs with its first commercial plant, according to Richard Tobey, vice president of research and development and engineering. Coskata plans to break ground on that plant, expected to make between 50 million and 100 million gallons of ethanol annually, this year and to have the plant up and running in late 2010 or early 2011.

But so far, price doesn't seem to have been the biggest holdup in the ethanol market.

While prices already are lower than gasoline -- ethanol also gets about 25 percent fewer miles per gallon, leading some analysts to content the price should be less than that of gasoline - and gasoline prices remain high, demand has remained comparatively low and companies have suffered from shrinking margins as the cost of feedstocks keeps growing (see Imperium IPO Delay Underlines Feedstock Shortage, Analyst Says, Biofuels Gain Green Despite Troubles and Ethanol Margins Suffer).

Still, Stanek said she is confident that demand will increase as the country strives to meet its 36-billion-gallon goal. And the low prices and large volumes that Coskata could bring to the market really could make a big difference, she added.

GM believes ethanol could eventually make up more than 90 billion gallons of the country's fuel consumption, which is estimated at 140 billion gallons today and projected to reach 180 billion gallons by 2030, she said.

"We have to get some stability back in," she said. "We have to be able to get fuel locally that isn't impacted by shocks around the world. We believe at least a third of our fuel could come from biofuel in the future."

Fuel From Waste

The potential for ethanol from nonfood crops has excited scientists, entrepreneurs and venture capitalists, who have poured money into its research and development.

That's because while today's ethanol is mostly made from starch-based materials, such as corn or sugarcane, its growth is limited. The U.S. Energy Information Administration in 2006 estimated that starch-based ethanol production will top out at 12 billion gallons a year -- at least using today's technologies - unless the industry taps into food crops.

That's far less than the 36 billion gallons per year that the country is required to use by 2022 under the new energy bill President Bush signed in December, and the bill mandates that 21 billion gallons of the goal must come from nonfood sources. Advocates contend that cellulosic ethanol could one day allow ethanol to meet a significant portion of the world's fuel needs.

But in spite of years of research, cellulosic technologies face major challenges to commercialization and haven't yet been able to produce cellulosic ethanol economically and in large volumes (see The Fuel of the Future? and Ethanol: Cellulose Break Down).

Among the challenges: Cellulosic-ethanol plants are estimated to cost two to three times that of starch-based ethanol plants, which cost roughly $150 million for a 100-million-gallon-per-year facility, said Jim McMillan, a manager at the National Renewable Energy Laboratory's National Bioenergy Center.

A Better Bug

Coskata thinks its technology using proprietary microorganisms and bioreactor designs can overcome some of these difficulties.

"Coskata technology is ready today and moving rapidly toward commercialization," Roe said. "This really is a promise for an alternative to gasoline that doesn't compete with what could be construed as food sources."

The company's process starts with the gasification of any of a wide variety of carbon-containing materials, such as agricultural waste, wood chips, old tires and municipal solid waste, into so-called "synthesis gas," which includes hydrogen and carbon monoxide. Then, the company plans to use proprietary bacteria and a new bioreactor design to convert the gas into ethanol.

Roe said the process generates 7.7 times the amount of energy it uses and reduces carbon-dioxide emissions by up to 84 percent compared to gasoline, according to analyses by the Argonne National Laboratory.

Coskata also claims it can use feedstocks and water more efficiently than its competitors, producing about 100 gallons of ethanol per dry ton of material using less than a gallon of water per gallon of ethanol.

While the net energy, emissions and feedstock-efficiency numbers are in the normal range for cellulosic technologies, the water-usage claim is significant considering that most ethanol technologies use about three gallons of water per gallon of ethanol, McMillan said.

But one challenge that approaches like Coskata's have faced is the problem of so-called "gas-liquid transfer," he said. Essentially, the bacteria live in water and "eat" synthesis gas, but only small amounts of gas can dissolve in water. So keeping enough nutrients in the water to efficiently make ethanol -- while making sure that gases that are toxic to the organisms are removed -- is tough.

Also, Coskata scientists aren't the only ones tackling a syngas approach, he said. Companies such as Alico and Khosla Ventures-backed Range Fuels -- both of which received funding from the DOE to build biorefineries -- also are working on converting synthesis gas into ethanol, as are researchers at Oklahoma State University, Mississippi State University and Brigham Young University, among others.

"There is some precedent here, so it's not like it's the first ever [to work on this approach]," McMillan said. "But nobody has scaled this process yet."

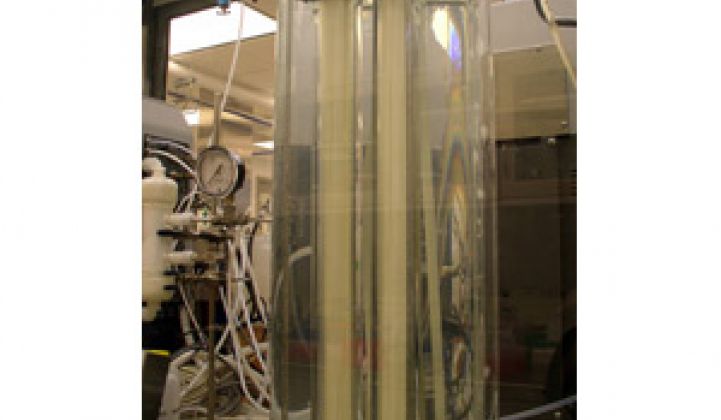

Coskata thinks it has solved the gas-liquid problem with its bioreactor design, which grows bacteria colonies in separate tubes that deliver the synthesis gas to the bacteria while sucking ethanol out and keeping water in.

And while she admitted there's always risk, Stanek said she isn't worried about Coskata's ability to take its technology from the lab to mass production.

"There are some [parts of the process] we're hoping will move more quickly, but they have been tested elsewhere," she said. "We feel the risks are very manageable."

Trashy Tech

Another challenge for cellulosic-ethanol companies has been the difficulty of gathering and transporting materials that aren't used for food today.

While companies say the production costs for cellulosic ethanol have the potential to be cheaper than that of conventional ethanol, because the nonfood materials are cheaper than food crops, setting up systems to collect and transport those materials have boosted those costs.

While Coskata hasn't selected the feedstock for its first plant, Roe said the company plans to start with materials that already are readily available and collected at central locations, such as wood chips, bagasse and construction debris.

"Ethanol from these new materials is coming faster than people think," Roe said.

Even with the rising prices of wood chips, he said, Coskata expects to be able to meet its price target with those feedstocks.

Later, the company plans to expand into crops such as switchgrass -- potentially cutting the cost of Coskata's fuel to half that of gasoline -- and also hopes to one day use trash, he said. After all, cities already collect and bring to one place -- the dump -- and trash should be cheap.

"I have a dream of paying for garbage, of it [being] of economic value rather than a waste," Tobey said. "It will change the world when people realize what they're throwing away is their transportation fuel."

But the waste would have to be separated before it could be processed, Roe said, adding that he thinks municipalities already will begin sorting trash by the time Coskata is ready to use it, years from now.

Making Money

The company certainly isn't waiting for its trash technology to be ready before it gets started, however.

Coskata plans to both license its technology to partners and build its own plants, but the first few commercial plants probably will be built through partnerships, Roe said.

"We think the fastest way to commercialize is to get serious partners, who want to build, own and operate the plants," he said. "We'll do licensing and also will be providing the organisms and nutrients. Like in the software business, there will be microorganism 1.0 now; then there will be version 2.0."

Stanek said the plan makes sense, especially in light of "very strategic" partnerships Coskata plans to announce in a few weeks.

"When you hear [about these partnerships], it'll make a lot of sense," she said. "They will facilitate a very quick ramp-up. I think people will be impressed with the rate of speed."