Another day, another LED startup. But Ecospark could be different.

Unlike the many advanced lighting companies whose LEDs produce blue light that becomes white after passing through a yellow phosphor, Sweden’s Ecospark claims that its LEDs will produce white light.

“Our solution gives us a natural light spectrum which resembles sunlight,” said Hans Lindberg, Ecospark’s Chairman. “We get white light. We have reached a color rendering index of about 90 without any phosphorus, which means higher efficiency and lower cost.”

Most LED companies use gallium nitride as their semiconductor. Gallium nitride emits blue light, which these companies turn white by coating their LEDs with yellow phosphor. In so doing, however, they reduce the efficiencies of their LEDs.

Ecospark is developing zinc oxide nanowire LEDs, which it believes will generate white light directly, without the use of phosphorous. (Editor's note: there's another stealthy company working on natural white light that we'll tell you about soon.)

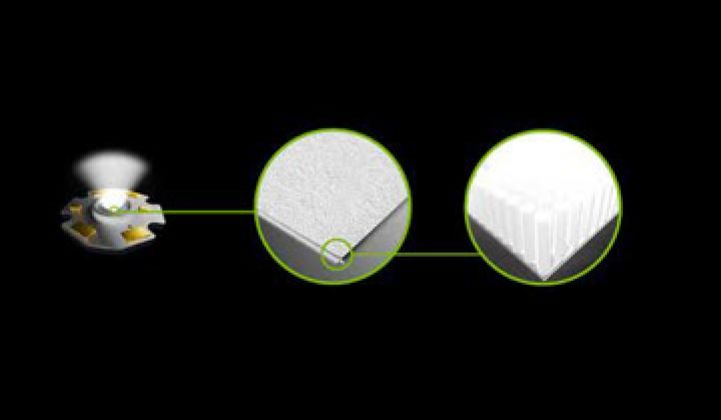

“We base our technology on using zinc oxide in the form of nanowires as the semiconductor,” said Lindberg at Boston Cleantech Venture Day. “The design is simple. We can use almost any substrate. On that substrate, we put a conductive p-type layer [that] could be silicon carbide, gallium nitride [or] a p-type polymer. On this layer we grow nanowires, we insulate around the nanowires, and on top, we put a conductive and transparent layer which then closes the circuit.”

Ecospark claims that its use of zinc oxide and nanowires will enable it to produce LEDs that cost less than those that use gallium nitride as their semiconductor.

"Today’s gallium nitride technology uses a very complex and expensive production methodology,” said Lindberg. “Our solution gives us a very cost effective design using low cost manufacturing method. [...] Nanowires are quite simple to produce. It is a low cost production methodology with wet chemicals.”

“If everybody is playing in the gallium [nitride] space and these guys have another space that is more cost effective, if the process is simpler… it could be a game changer,” said Frank Balas, a technology specialist at Emerald Technology Ventures. “We have to look at the details.”

Ecospark is working to commercialize the research of Swedish Professor Magnus Willander of Linköping University, a company co-founder. After establishing proof of concept, filing patents to protect both its design and manufacturing processes, and raising $500,000, mostly from angels, Ecospark now seeks $1.2 million for product and process development, distribution of samples and customer testing.

Initially, the company will produce LED chips, which it will sell to LED packagers (which will in turn aggregate the chips and sell the packages to companies that produce lighting fixtures). Later, Ecospark will produce flexible LED panels.

Ecospark’s approach is not entirely unique. MOXtronics, a University of Missouri spinout, has been pursuing zinc oxide LEDs for years. Founded in 2008, Boston-based LumenZ is also developing zinc oxide LEDs. LumenZ has raised $8 million from Khosla Ventures, General Catalyst Partners and New Venture Partners. Though LumenZ does not have a website and has to date been largely quiet about its intentions, it too intends to sell LED chips to upstream players.

But Ecospark believes that its design differs in a critical respect.

Semiconductor production involves doping, the process of inserting into a solid’s crystal lattice impurities that either release an electron (n-doping) or absorb an electron, which creates a “hole” (p-doping). These additional electrons and “holes” then enable the solid to conduct electricity. To date, scientists have struggled to develop a process to manufacture stable, reliable p-doped zinc oxide (though in 2007, researchers at the University of California, San Diego claimed just such a breakthrough).

“Why us?” asked Lindberg. “There are different groups try[ing] to do zinc oxide LEDs, but all of them [use] p-doped zinc oxide and n-doped zinc oxide -- and it is difficult to make p-doped zinc oxide. We have a proprietary design and use only n-doped zinc oxide and another p-doped material. We do not use p-doped zinc oxide.”

***

Yoni Cohen is a JD-MBA student at the Yale Law School and the Wharton School at the University of Pennsylvania. A former college basketball writer for Fox Sports, he tweets about cleantech @cohen_yoni.