It is fair to say that green technology has moved beyond composting. Driven by the facts of global climate change, rising energy demand and shrinking fossil-fuel reserves, green technology has developed into a significant growth market. In 2006, green-technology companies received $3.9 billion in venture-capital investment and generated $55 billion in revenue. The year also was successful for firm exits, with green-technology companies raising $4.9 billion in IPOs -- nearly doubling 2005's record total -- and completing nearly 450 M&As. Behind this record-breaking market expansion are a widening array of technologies, processes, applications and services that are helping consumers, businesses, utilities and governments create a clean and sustainable world.

Green technology is a necessary solution to a complex problem -- generating economic growth without sacrificing the environment. Specifically, green technology is anything that seeks the efficient use of natural resources to limit or negate environmental impact while reducing costs and raising revenues, profits and value. It generates positive social, environmental and economic externalities across the entire product life cycle with innovative crossover technologies, processes, applications and services. This system constitutes a market in the broadest possible sense: The demand for a better quality of life and a healthier environment is met by a supply of innovation and capital that cuts across the industrial and knowledge economies.

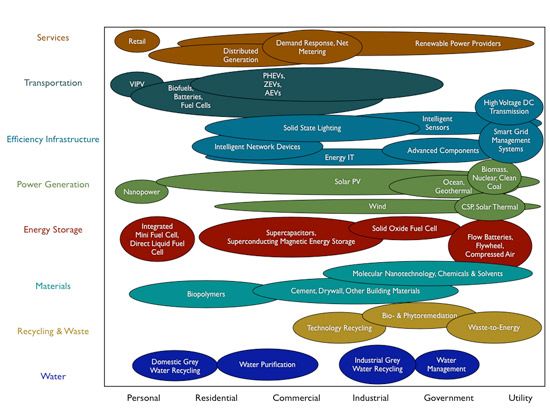

Keeping track of the growing number of players and technologies is a major business challenge for green technology. The market has moved past power generation, branching out into sectors that affect nearly every aspect of modern life. Dressing, driving and eating are a few, and the list goes on. Who these technologies affect and the level at which they operate are becoming increasingly important questions for investors and entrepreneurs alike. Understanding the value of green technology requires one to understand the composition of the market.

This taxonomy represents Greentech Media's belief that green technology is understandable in an intuitive way. We have organized the green-technology market to reflect how the end user might interact with the variety of technologies, processes, applications and services flowing into the field. In the green-services sector, for instance, a homeowner might take advantage of retail PV outlets and systems integrators, while a demand-response program might make more sense for a mall or grocery store. By organizing the market in this way, and then by discussing each aspect of the market in depth, we have added a level of accessibility to the green-technology market where none previously existed. The companies we decided to include here were selected largely on the maturity of the technology. In some areas, only a handful of companies operate. In other areas, such as solar or wind, we have selected a mix of established producers and promising start ups. The company lists are not exhaustive, as new companies are entering the market almost every day.

An important aspect of the Greentech Media Taxonomy is the level of interaction we hope it will engender. The green-technology community is incredibly diverse, spanning science, business, government and you -- the end user. Though the initial taxonomy is intended as a top-down framework to structure the market, it is our hope that it will evolve with your input, criticism and comments. Our goal is to have this taxonomy develop into a folksonomy, driven as much by your knowledge as that of our analysts. We admit that the Greentech Media Taxonomy is far from complete. Instead, it is a starting point from which we plan to develop a reference point for the entire green-technology community.

Power Generation

Green-power generation sources reduce significantly the need for fossil-fuel-based electricity generation. Electricity is generated primarily by burning coal and natural gas. While these fuel sources have a lower cost per kilowatt than green-power-generation sources, this will soon cease to be the case. Many observers believe fossil-fuel production will decrease dramatically in the next half-century, and will end completely before 2100. During that period we can expect energy consumption to increase dramatically, driving up costs for fossil-fuel-generated electricity. Cost increases and the ongoing negative environmental effects caused by fossil-fuel use are driving homeowners, businesses, governments and utilities to develop and adopt green-power-generation sources.

Green-power generation is among the most advanced segments of the green-technology market. Several technologies, such as wind and solar power, are commercially available now. Ocean-power technology and hydrogen production from sulfur-deprived algae are in development and prototyping stages. Government incentive programs and a steady stream of investment capital are driving growth in this segment. Investment and research support are expected to increase to match the growing economic and environmental costs of fossil-fuel-generated electricity.

Key Components

Renewables - Renewable energy sources such as wind, water, geothermal steam, biomass and solar provide zero-emission, zero-fuel-cost power to national power grids, commercial buildings and residential units. Efficiency gains in power generation coupled with low-cost scaleable technology are driving growth in this component, and helping it to garner the largest share of investment dollars in green technology. In more established technologies such as wind and solar, investment is migrating into different parts of the supply chain as companies continue innovating to bring down capital costs. Other technologies, such as ocean power, are achieving higher rates of early stage investment, which is driven by the confluence of technology advancements and positive policy climates.

-

Solar Power - Solar power derives energy from the sun and converts that energy into electricity using photovoltaic (PV) panels or energy-conversion systems. Solar-power technology, while advanced and commercially available, produces electricity subject to available sunlight, making it suitable for peak-power support but unusable as a base-load system.

Veterans Q-Cells AG Suntech Solon AG Trina Solar ReneSola China Sunergy LDK Solar Startups Day4 Energy Solaicx Silicon Valley Solar SolarWorld Veterans First Solar United Solar Ovonic Miasolé XsunX ICP Solar Startups Xunlight G24 Innovations Wakonda Technologies Heliovolt Nanosolar Sierra Solar Concentrated PV SolFocus Concentrated Solar Power (CSP) & Solar Thermal Solel Ausra BrightSource Energy eSolar - Polysilicon - Polysilicon panels and arrays are the most common form of solar-power generation. Polysilicon cells are collections of silicon wafers, made from either monocrystalline or polycrystalline silicon. The most advanced polysilicon cells reach efficiencies of 11 percent to 18 percent, though new production technologies offer higher efficiency possibilities. Most polysilicon cells are only able to capture visible areas of the light spectrum.

- Thin Film - High silicon prices have driven research into non- and low-silicon semiconductor materials, such as copper indium gallium diselenide, cadmium telluride and amorphous silicon. Thin films are less expensive by cost per kilowatt compared to polysilicon, but low efficiencies (5 percent to 8 percent) require large amounts of area for deployment. Thin films are able to capture light in invisible parts of the spectrum and during low-light periods and in low-light areas. The technology involved in manufacturing these materials is complex, and continued research in assembly and production processes are required to bring down costs and increase market share.

- Concentrated PV - Concentrated PV arrays focus light onto polysilicon solar panels to increase the energy intensity and conversion efficiency of traditional PV panels. CPV requires less polysilicon than traditional PV arrays. This technology often employs single- and dual-tracking systems to keep pace with the sun as it moves across the sky.

- Concentrated Solar Power (CSP) & Solar Thermal - CSP and solar thermal reflect energy from the sun onto mirrors, which heats oil or water, and creates steam to power traditional-energy turbine generators. Parabolic trough and dish designs are effective means of concentrating solar heat and converting it into electricity. Excess superheated material can also be maintained in reserve and used to spin turbine generators when sunlight is not available.

-

Wind Power - Wind turbines spin to convert mechanical energy from wind into electrical energy. Like solar power, wind power is subject to source intermittence problems from poor siting and low (or high) wind speed. Most wind-power production occurs during off-peak hours. Turbines are across generating scale, from distributed generation to grid-tied offshore wind farms. Wind power is driven primarily by a number of established and startup companies developing utility-scale onshore and offshore wind farms. These companies are listed below.

Veterans Vestas Ecotècnia Suzlon Energy Alubar Energia General Electric Windflow Startups Clipper Windpower Vibrating Turbine Humdinger Wind - Maglev Wind Turbine - The magnetically levitating bearings in maglev wind turbines are more sensitive than traditional bearings, and achieve cut-in at low wind speeds. Maglev turbines are also able to spin at higher wind speeds compared to traditional turbine designs. While not commercially available, prototype designs are aimed at utility-scale power generation.

- Vibrating Turbine - Though technically not a turbine - it doesn't spin - the vibrating turbine has many potential uses in areas where spinning turbines are too large or too expensive to install. Vibrating turbines capture energy created by the vibration of taut, vertically aligned membranes through aeroelastic flutter effects. These are small devices intended primarily for roof-mounted distributed generation, though scale-up technology may be possible with continued research.

-

Ocean Power - Ocean-power technology converts mechanical energy from the near-constant movement of tides, currents and waves into electrical energy. The constant movement of water, combined with high potential and kinetic energy density, make ocean power an ideal candidate for base-load power generation, especially for off-grid island communities and areas with high-energy weather patterns and turbulent seas. Ocean-power devices are built around technology similar to that found in offshore oil and natural-gas platforms. Construction processes are capital-intensive and require high-grade, heavy-duty materials.

Veterans WaveDragon OceanLinx Ocean Prospect Ltd. Wavegen Startups SeaPower Pacific Ltd. Finavera Renewables Ocean Power Technologies British AWS Ocean Energy Ltd. Pelamis Wave Power Fred Olsen Ltd. Veterans Blue Energy Canada SMD Hydrovision Startups Verdant Power Tidal Energy Pty Ltd. Marine Current Turbines Ltd. Open Hydro Ocean Renewable Power Co. LLC Ocean Thermal Energy Conversion (OTEC) Common Heritage Corporation - Wave Power - Wave power converts the elliptical kinetic mechanical energy of ocean swells into electrical energy. There are a variety of wave-power devices, including buoys, oscillating water columns and overtopping reservoirs. All devices act essentially the same: They use pressurized sea water to spin turbine generators located within the device body. A handful of prototype wave farms exist in the Pacific Northwest and in northern Europe, where prevailing sea breezes create the biggest ocean swells. Wave-park development and device deployment is largely dependent on government support.

- Tidal & Current Power - Marine-propeller or shrouded-turbine installations are designs similar to wind turbines. High water density and constant tidal and current flows allow these devices to achieve high conversion efficiency and constant power output. However, tidal and current patterns work over extended periods typified by 25-hour patterns and diurnal flux, so power-output times often misalign with peak power demand.

- Ocean Thermal Energy Conversion (OTEC) - Pumping near-freezing water through temperature zones in the ocean and onto shore to power heat engines is a relatively little-understood technology. High capital costs - OTEC requires well-insulated pipes sunk a mile or more into the ocean - have stunted growth in this technology. This technology has a range of side uses, including water desalinization and soil regeneration.

-

Biomass - Biomass conversion consists of harnessing the potential chemical energy within carbonaceous matter through burning and gas conversion. Early technologies converted biomass directly into heat. Advances in production and chemical and genetic engineering have found new uses for biomass, including conversion into liquid fuel and hydrogen. Realizing commercial-scale energy output is still largely dependent on creating efficiency gains in production technology and outsized investment in production facilities.

Hydrogen From Algae LiveFuels, Inc. GreenFuel Technologies Corp. Biomass Gasification Biomass Technology Group >ZeroPoint Clean Tech, Inc. -

Hydrogen from Algae - Algae can be engineered to produce hydrogen instead of oxygen during photosynthesis through sulfur deprivation. Prolonged sulfur deprivation has negative effects on the algae, so this process currently can occur only in short cycles. Continued research is required to lengthen sulfur-deprivation periods. Furthermore, commercial scale generation requires large, open bioreactors to harness the power of a critical mass of algae. There are currently no bioreactors large enough to accomplish this. If successful, though, sulfur-deprived algae could be the most efficient and sustainable means of creating hydrogen.

- Biomass Gasification - Gasifying organic material (wood pellets, leaves, tree bark and livestock and poultry manure) consists of burning this material at high temperatures while mixing it with oxygen, which breaks down the carbon monoxide and hydrogen contained in the organic material. The result is a clean-burning, carbon-neutral synthetic gas. Inorganic matter left over from this process can be used as fertilizer. Syngas can be further converted into biomethane and methanol or carbon-neutral synthetic fuel with continued catalyst processing.

-

Geothermal Power - Underground thermal energy is nearly limitless. Geothermal-power plants pump underground steam and hot water and use the heat supplied to spin turbine generators. Major costs of geothermal-power plants come from exploration and excavation, and current technology is only cost-effective in areas with active underground tectonic movement observable through geysers and volcanic activity. Research on stimulating underground heat and creating artificial heat reservoirs might make geothermal power a promising source for base-load power.

Enhanced Geothermal Systems (EGS) Altarock Energy Geodynamics Geopower Basel Hydrothermal Power Nevada Geothermal Power Enel Green Power EarthEnergy Ormat Technologies, Inc. -

Enhanced Geothermal Systems (EGS) - EGS might provide a cost-effective work-around for areas where available geothermal power is located far below ground. These systems create permeable rock layers through high-pressure water injection, which is heated through contact with newly fractured rocks. The water is then pumped back above ground and used to spin turbine generators. Stimulating underground heat production and artificially engineering heat reservoirs is expensive, though, and requires vestment in pilot plants to prove its usability.

- Hydrothermal Power - Hydrothermal is the more traditional form of geothermal power. It relies exclusively on existing reservoirs lying under permeable rock that are saturated with steam or heated water. Geographic limitations notwithstanding, areas where these resources are readily available at short distances below the surface will benefit from adopting this technology.

-

Nuclear Power - Generating electricity from controlled nuclear reactions appears to be an efficient method of providing pervasive base-load power, though safety, environmental effects and costs must not be disregarded. Nuclear reactors are costly, upwards of $2 billion, though once built the power plants can run continuously. Internalizing costs across the fuel-production process increases the electricity costs from "too cheap to meter" to thousands of dollars per kilowatt-hour. There is also widespread debate about whether nuclear power is truly renewable, as it requires uranium fuel -- a depleting mineral -- for fission. Less than 2 percent of uranium is fissionable. Another substantial problem is thermal water pollution and reactor waste disposal. Neither problem has yet been solved. Public skepticism and fear also are major factors preventing the widespread adoption of nuclear power. These fears are not unfounded.

Several new theoretical technologies for nuclear reactors are currently under research. These new designs focus primarily on cooling mechanisms and non-uranium 235 fueling, including hydrogen-based nuclear fusion. Although the last commercial reactor in the U.S. was completed in 1996, nuclear power makes up nearly 16 percent of global electricity production. It has a particularly strong presence in Western Europe, Japan and Russia. Both General Electric and Westinghouse are currently seeking approval for new reactor designs from the U.S. Nuclear Regulatory Commission, the first such submissions in 30 years.

-

Experimental Power - Early stage and experimental technologies are at the farthest edges of green technology. Primary examples of experimental green-power generation use nanotechnology to generate constant power for miniature devices or to provide less resistance for electricity pathways in green-technology devices.

Microgenerators PMG Perpetuum Steorn Nano Solar InnovaLight, Inc. >Eikos, Inc. >Suniva -

Microgenerators - Microgenerators harness mechanical energy from ambient vibrations and ultrasonic waves to vibrate arrays on nanowires across a saw-shaped electrode. A number of different prototypes currently exist, in sizes appropriate for devices ranging powering nanorobots to larger industrial sensors. A potential application for microgenerators is powering internal medical devices such as pacemakers.

- Nano Solar - Light is present even at the smallest scales and new research is being done to take advantage of that. Coaxial silicon nanowires concentrically align different grades of silicon into a wire which acts as an electron harvester and proton-transfer unit. Coaxial nanowires are able to self-power nanowire-based logic circuits. Nanoparticle solar cells operate in a similar way. They transmit light through a series of carbon nanotubes, which pass electrons through electrodes to generate electricity. Another technology suspends silicon nanocrystals in a solvent to create silicon nanocrystalline ink, which can be poured on virtually any surface. While achieving efficiencies similar to polysilicon cells, nanocrystalline ink costs about 50 percent less to produce.

-

Clean Coal - Fossil fuels will continue to be part of our energy mix for a number of years. While we wait out the death of coal, which some analysts predict will occur in the next 50 to 60 years, technologies developed and deployed today aim to reduce the impact that coal has on our environment. Clean coal technologies reduce the CO2, NOX, SOX, and CO content of coal plant effluent, capture and sequester these pollutants and convert coal into carbon-neutral liquid fuels for electricity generation. The U.S. government has sunk a considerable amount of money into the FutureGen project - the coal power plant of the future. FutureGen is a zero-emissions coal plant that combines coal-to-hydrogen conversion with carbon capture and storage. Waiting for FutureGen, which has a planned deployment in 2012 but currently lacks a final site, seems like a losing bet.

Internal Gasification Combined-Cycle (IGCC) Altarock Energy Xcel Energy GreatPoint Energy Oxy Fuel Clean Energy Systems, Inc. -

Internal Gasification Combined-Cycle (IGCC) - A process of high-temperature coal gasification that creates syngas from the carbon monoxide and hydrogen end product. The syngas is combusted and used to power a turbine generator. The remaining heat and steam are also used to spin turbine generators. IGCC enhances the efficiency of coal-powered electricity generation while reducing emissions. Retrofitting coal plants for IGCC operation is cost-prohibitive, while new construction costs come out to roughly $3600 per kW (20 percent more than a typical coal power plant), when construction and operation costs are added in. However, IGCC plants are able to capture CO2 during gasification, significantly decreasing pollution levels.

- Oxy Fuel- This new technology uses oxygen-enriched gas to fire coal power plants. The oxy-fuel process yields an effluent stream that is nearly pure oxygen, and leads to a 75 percent reduction in the amount of flue gas. Oxy-fuel combustion for electricity generation is less efficient compared to IGCC, but its end-product effluent captures and stores CO2 more effectively. Oxygen production is currently the most expensive component of oxy-fuel combustion.

Transportation

Green transportation technologies refer to both the cars themselves and to what makes them move forward (and backward - or up and down). While vehicles are about as high up on the value chain as you can get, their key components are innovative green power sources that are lightweight, durable, high-performance and long-lasting. The trajectory of green vehicles is advancing away from fossil-fuel-only or fossil-fuel hybrid vehicles toward vehicles that use a combination of on-board electricity generation, biofuel and standalone electricity storage.

Bringing zero-emission vehicles (ZEVs) to commercial scale is dependent on increasing the storage capacity of batteries while decreasing their size and weight, increasing the availability of fuel for fuel cells and producing carbon-neutral biofuels on a level equivalent to gasoline. Growth trends in the transportation segment are all leading toward commercial-scale ZEVs. Technological issues aside, a number of growth-impeding infrastructure deficiencies exist. Funding and investment for biofuel-production facilities and distribution infrastructure are scarce, which limits the wide-scale reliability of vehicles reliant on these fuel sources.

Key Components

-

Battery - Lightweight, high-density, quick-charging batteries are one of the key technologies competing to power electric vehicles. Rechargeable batteries in battery electric vehicles (BEVs) accelerate quickly and are able to achieve high speeds. BEVs with regenerative braking allow for battery-energy conservation, increasing distances between charging. One factor holding back wide-scale deployment of BEVs is recharging speeds and capacities. Continued research into fast-charging vehicle-grade batteries, as well as infrastructure investment for vehicle charging, is required before BEVs make significant inroads.

Lithium Ion (Li-ion) A123Systems Valence Technology AltairNano Lion Cells Lithium Polymer (LiPo) Sion Power >Protanium Nickel Metal Hydride (NiMH) ECD Ovonics - Lithium Ion (Li-ion)- Li-ion battery power systems are found in most BEVs, such as the Tesla Roadster and the Smart Car. These batteries are durable and can be made into virtually any shape, which makes them especially useful for installation in tight spaces within cars. Li-ion batteries also have a cycle durability of 1200, high-energy density, fast recharge rates and rated distances of between 250 miles and 300 miles per charge. Despite these aspects, li-ion batteries require a number of internal safety measures to prevent overheating or combustion that take up increased space within the battery. Li-ion batteries have time-dependent life spans and they begin to deplete soon after production.

- Lithium Polymer (LiPo) - LiPo batteries are the next evolution of Li-ion batteries. Their fundamental strength is in the lack of a hard metal casing, which makes these batteries considerably lighter than their Li-ion predecessors. The newest technology extension of LiPo is the thin-film polymer electrolyte battery, which has a higher energy density than Li-ion and which use thin-film plastics to make them smaller and more flexible. LiPo batteries are also considered safer than Li-ion batteries. Where the primary electrolyte in Li-ion is suspended in a solvent, LiPo batteries hold electrolytes in a solid-state composite. LiPo batteries are currently deployed in electric bicycles, but continued research is needed to bring these batteries into BEVs.

- Nickel Metal Hydride (NiMH) - NiMH batteries appeared in the first modern BEVs, including the GM EV1 and the Honda EV Plus. Compared to nickel cadmium batteries, NiMH batteries have a higher energy density and lower observable memory effects – they maintain their whole charge capacity for longer. NiMH batteries also have a low internal resistance, which allows them to maintain an almost constant voltage output. However, NiMH batteries are heavier compared to Li-ion and LiPo while also having lower charge-cycle durability. These batteries are used in the Toyota Prius and the Honda Insight.

-

Fuel Cell - Fuel cells convert electrochemical energy into electricity, which is used to power an electric traction motor. Fuel cells work by combining a fuel (hydrogen, methanol) with an oxidant (oxygen) that then reacts across an electrolyte membrane. These systems can work almost continuously as long as they are provided with a constant stream of fuel.

Proton Exchange Membrane Fuel Cell (PEM) Giner Electrochemical Systems, Inc. Ballard Power Systems Direct Ethanol Fuel Cell (DEFC) Projekt Schluckspecht - Proton Exchange Membrane Fuel Cell (PEM) - PEMs are the most widely used type of vehicle fuel cell. These use electricity produced from hydrogen (like other fuel cells), but are able to do so at low-temperature and low-pressure ranges, which makes PEMs ideal for use in smaller cars. PEMs, like most fuel cells, require reformed hydrogen, which must be passed through an extremely hot, highly pressurized catalyst within the vehicle before it is injected into the fuel cell.

- Direct Ethanol Fuel Cell (DEFC)- DEFCs use non-reformed ethanol to feed into a fuel cell. By not reforming the fuel, these systems do not require a catalyst, which makes for easier storage without pressure or temperature requirements. DEFCs are also promising because they rely on planned or preexisting ethanol distribution infrastructure, which is more of a reality than a hydrogen distribution infrastructure. DEFCs have limited efficiencies and power densities, but the possibility of widespread non-hydrogen fuel cells is a promising opportunity.

-

Biofuel - Converting biomass into liquid fuel for transportation is a natural extension of the biomass processes used in electricity generation. Biofuel commercialization is currently moving in two directions. One focuses on creating ethanol from sugar fermentation and biobutanol from starch fermentation, while the other focuses on engineering biomass to mimic the chemical structure (and energy output) of petroleum.

Biobutanol Green Biologics Synthetic Ethanol LS9 Amyris Biotechnology SunEthanol -

Ethanol- Ethanol is a liquid fuel produced from fermenting sugar found in biomass.

Corn-Based Ethanol BioFuel Energy, LLC Iroquois Bio-Energy Company Sugarcane Ethanol Ethos >Farmacule BioEnergies Cellulosic Ethanol Verenium Range Fuels Mascoma Iogen Corp. -

Corn-Based Ethanol- Corn-based ethanol is produced from the fermentation and distillation of sugars found in the vegetable part of the corn plant. It is considered relatively inefficient, as energy costs of materials are high and energy output is low. Corn production is both land- and energy-intensive, and common industrial agriculture practices rely heavily on fossil fuels to manufacture corn at such high intensities. Despite widespread government support for corn-based ethanol production, there is relatively little support for infrastructure development to distribute this kind of biofuel.

- Sugarcane Ethanol - Sugarcane ethanol is made from the cane itself, as well as the waste -- bagasse -- left over from harvesting. The cane and bagasse are ground down, fermented with yeast and distilled to create ethanol. This is a more efficient process than creating ethanol from starch-based biomass, as the starch needs to be converted to sugar before it can be processed into ethanol.

- Cellulosic Ethanol - Cellulosic ethanol uses almost the entire biomass of a plant - lignin, cellulose and hemicellulose - to produce biofuel. Ultimately, cellulosic ethanol achieves a higher sustainability and lower environmental impact than traditional corn or sugarcane ethanol. It is also cheaper to produce than corn or sugarcane ethanol, since its feedstock consists of nearly all plant biomass. Cellulosic ethanol is produced from plant waste, which means food supplies are not diverted for fuel production. This is a concern with both sugarcane- and corn-based ethanol. There are currently a handful of demonstration plants in the U.S. that are producing good results, but which require continued investment to scale up late-stage development.

- Biobutanol - Biobutanol is a biofuel derived from the starch fermentaton of biomass. Its chemical makeup is more similar to petroleum than ethanol, and it achieves a higher energy density than ethanol. Biobutanol's primary benefit is its transportability. Unlike ethanol, biobutanol is neither corrosive nor hydrophilic, which means it can be transported across existing pipelines without eating them. Biobutanol's primary drawback is the inefficiency of its production process. Typical biobutanol fermentation yields only a small amount of useable liquid fuel -- less than 5 percent -- and it is very energy-intensive.

- Synthetic Biofuel - Synthetic biofuel mimics the chemical structure of petroleum to achieve petroleum's energy intensity without its carbon emissions. By engineering feedstock to act like petroleum, synthetic biofuel overcomes the compatibility problem faced by other biofuels. No new distribution infrastructure or automobile parts are needed for synthetic biofuel to become part of the energy mix. However, it is only produced by a handful of companies and is not yet available on a commercial scale.

-

Ethanol- Ethanol is a liquid fuel produced from fermenting sugar found in biomass.

-

VIPV - Vehicle integration of PV cells to provide complete power is a long way off. However, a niche consumer industry has developed to begin providing this technology as a supplement to ZEVs and PHEVs. Integrating thin-film panels on EVs could power on-board energy systems or provide immediately available starting power for drained batteries. Ultralight research VIPV vehicles do exist, though they resemble airplanes more than cars and fit only one person, uncomfortably.

Green Vehicles Tesla Motors ZAP! Th!NK Aptera Venture Vehicles Venturi Reva Electric Car Company - Green Vehicles - Green vehicles are closely associated with the technology used to drive them. Often, the propulsion technology's inventor and the vehicle's manufacturer are the same company. Here's a quick rundown of some of the most important and interesting green-vehicle manufacturers.

Energy Storage

Energy storage is the backbone of the green technology economy. Storage technologies address power-source predictability, which many believe is a significant obstacle to the widespread adoption of green power-generation technology. Green energy-storage technologies also provide sustainable solutions for consumer electronics and transportation technologies.

Storage systems are grouped by storage method. Grid-storage technology is currently used to supplement diurnal power supplies, charging from nighttime base-load power and supplementing peak power demand during the day. When providing storage for green power generation, this technique would be reversed. Storage systems would charge during the day, collecting excess solar or wind energy, and would then provide base-load power at night.

Key Components

-

Electrochemical - Electrochemical storage converts chemical energy into electrical energy and works in a way similar to fuel cells. A primary difference between fuel cells and electrochemical storage is the flow rate. Electrochemical storage maintains fuels and electrolytes outside of the reactor, pumping them through when electricity is needed. Fuel cells require a constant flow to generate electrical energy. The energy in electrochemical storage is determined by the amount of stored fuel, which can be recharged by processing through the reactor.

Solid Oxide Fuel Cell (SOFC) Bloom Energy SiEnergy Systems LLC Franklin Fuel Cells Integrated Mini Fuel Cell Tekion >Smart Fuel Cell Direct Liquid Fuel Cell Medis Technologies - Vanadium Redox Flow Battery- Flow batteries are designed primarily for large-scale grid energy storage. Charged electrolyte fluid stored in large tanks is pumped through reactor cells and reacted upon, converting chemical energy into electrical energy. Excess fluid is held in outside tanks and re-energized before it passes through the reactor. By adding new tanks, flow batteries are easily scaled up. Vanadium redox flow batteries solve ion leakage, which was a major problem in maintaining functional flow batteries.

- Zinc-Bromide Hybrid Flow Battery- Hybrid flow batteries differ from redox flow batteries in that hybrid flow batteries are limited in the amount of charged electrolyte they can process. Hybrid flow batteries require some amount of charged electrolyte to remain in the reactor, limiting storage ability and variable power output.

- Solid Oxide Fuel Cell (SOFC)- Solid oxide fuel cells operate at extremely high temperatures (700° to 1000° C). High operating temperatures negate the need for the platinum catalyst required in kinds of non-reformed fuel cells. Solid oxide fuel cells are currently stationary storage devices - due to the high operating temperature - but are useful in providing backup power to gas turbines through hybrid heat and power devices. SOFCs are also used for co-generating hydrogen (through excess fuel production in fuel electrolysis) and electricity. Current research is focused on decreasing their operating temperatures for use in automobiles and mobile devices.

- Integrated Mini Fuel Cell - A fuel cell's fuel-storage component often dwarfs the cell itself. One possible work around is storing hydrogen as methanol - liquid fuels store compactly - and freeing the stored hydrogen through a heating process. These are known as microchemical systems. Current research has developed the technology to process methanol in a series of concentric rings, with the core acting as a combustion unit that heats the rings to strip hydrogen out of the methanol solution. Integrated mini fuel cells can be as small as 5 centimeters in diameter, allowing them to fit into laptops, and can generate as much as 1000 watts/kg.

- Direct Liquid Fuel Cell - Storing hydrogen in sodium borohydride and combining that hydrogen with oxygen from the air is an efficient way of getting big power into compact spaces. Sodium borohydride has the advantage of high-capacity, small-volume hydrogen storage. It is also inflammable, alleviating a major concern with consumer-electronics fuel cells. A downside of this technology is that its power capacity is about the same as the most advanced li-ion batteries. Current research is focused on increasing the hydrogen content of the sodium borohydride, without increasing the boron-oxide byproduct. Some researchers have had success with adding ethylene glycol, a common ingredient in antifreeze.

-

Electrical - Electrical storage is an efficient way of delivering power without the need for chemical or mechanical conversion. Storing electrical energy is likely the most efficient way of maintaining electricity because there is no conversion element required.

Supercapacitors EEStor Flywheels Pentadyne Energy Corp. Vycon Compressed Air Energy Storage (CAES) CAES Development Co. General Compression - Supercapacitors- Supercapacitors store electricity in their charge field and have almost infinite charge cycling. These storage devices contain of a thin-film polymer dielectric sandwiched in between two oppositely charged metal plates. Carbon nanotubes create porosity in the dielectric, which brings the metal plates closer and generates a more intense electric-field charge. Although they have a lower energy density than batteries, supercapacitors charge in milliseconds and emit high-voltage bursts, which are useful for starting engines in battery-drained ZEVs as well as for load leveling in power-generation systems.

- Superconducting Magnetic Energy Storage (SMES)- SMES systems capture DC currents in the magnetic field of a cryogenically frozen superconducting coil and store that energy for an infinite amount of time. They allow for nearly instantaneous power output at high bursts over short periods and are useful for load leveling and grid stabilization.

- Mechanical- Mechanical energy-storage methods rely on the potential energy of mechanical motion. Energy conversion from potential to kinetic energy involves some efficiency losses, though it is the least technically complex form of energy storage. A widely used form of mechanical energy storage is water pumping, where water is moved to a higher elevation and pumped through a turbine generator. Mechanical storage requires high capital investment and construction costs. However, it is the most commercially advanced of the green energy-storage technologies and the only technology currently available to provide pervasive base-load support for green power-generation sources.

- Flywheels- Flywheels are wheels suspended in vacuum tubes and supported by bearings. Hybrid systems in newer technologies combine magnetic bearings with high-temperature superconduct