While most biomass-to-biofuels systems burn feedstocks as the first step in biofuel production, Sundrop uses concentrated solar energy to gasify the feedstocks into syngas that is then made into advanced biofuels. According to the company's website, the very high temperatures of CSP create efficiencies in the process:

At the center of the Sundrop Fuels process is our proprietary SurroundsunTM technology, a solar-thermal biomass gasifier that generates temperatures of more than 1,300 degrees Celsius (2,370 degrees Fahrenheit) from the concentrated power of thousands of solar heliostat mirrors. Using solar energy to drive the endothermic gasification reaction ensures the most efficient use of biomass feedstock to produce liquid advanced biofuels like renewable "green" gasoline.

Sundrop owns at least one U.S. patent and two pending U.S. patent applications relating to its solar gasification technology.

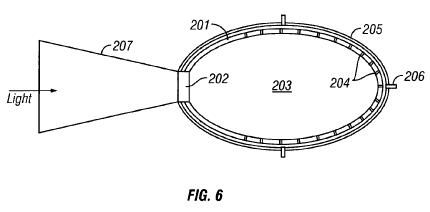

U.S. Patent No. 7,140,181 ('181 Patent), is entitled "Reactor for solar processing of slightly-absorbing or transparent gases" and is directed to methods for solar-powered processing of gases.

The methods described in the '181 Patent comprise directing concentrated sunlight through an aperture (202) into a spherical chamber (203), where the energy is partially absorbed by the walls (201) of the chamber and partially reflected.

Process gas is pumped into the chamber (203) through the aperture (202) and heated by contact with the walls (201) and by infrared radiation from the walls so the gas partially dissociates.

The gas exits through exit holes (204) and is quickly cooled by its contact with cooling surface (205) to prevent recombination. It then flows out exhaust tube (206).

Sundrop's two published patent applications are U.S. Application Pub. No. 2009/0313886, entitled "Various methods and apparatus for solar assisted chemical and energy processes" ('886 Application) and U.S. Application Pub. No. 2010/0000874, entitled "Various methods and apparatus for solar assisted fuel production" ('874 Application).

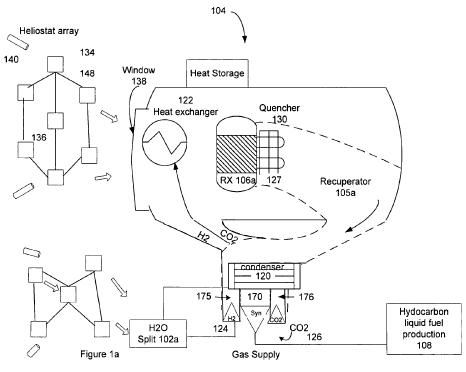

The '886 and '874 Applications are directed to solar-assisted water splitting processes and apparatus to supply synthesis gas for creating a hydrocarbon liquid fuel. A watter splitter (102) supplies H2 gas to a reverse water gas shift (RWGS) unit (104) that generates synthesis gas for production of liquid fuel such as methanol.

The RWGS unit (104) includes a reverse water gas shift reactor (106) and a liquid fuel synthesis reactor (108) that forms methanol from carbon dioxide hydrogenation.

A field of heliostats (134), or sun tracking mirrors, reflects sunlight onto the heat exchanger (122) through a window (138) in the RWGS unit (104). The solar energy drives the water-splitting process.

According to this Ecogeek piece, by using concentrated solar energy, Sundrop's process more than doubles the yield of fuel that can be produced using ordinary biomass burning processes to 100-125 gallons of fuel per ton of biomass.

Eric Lane is a patent attorney at Luce, Forward, Hamilton & Scripps in San Diego, where he works in the Intellectual Property and Climate Change & Clean Technologies practice groups. Mr. Lane can be reached at or at [email protected]. He authors the Green Patent Blog.