The Khosla Ventures-funded Stion is setting records in the lab for its tandem CIGS thin-film solar cell.

The firm just announced that it has produced a 23.2 percent efficiency thin-film cell using its tandem process.

Back in 2011, Tom Cheyney, writing for PV-Tech (and now with Impress Labs), reported on Stion's tandem architecture. He noted that "Stion may be the only CIGS player that has been pursuing a tandem-junction architecture from day one." He quoted CEO Chet Farris as saying, “It’s a mechanically stacked tandem; the device structures are built completely independent of each other."

Farris continued, “We already have two sheets of glass, so we exploit the second sheet of glass for the tandem, and the EVA acts as the dielectric between the two pieces of glass. It’s a four-terminal device that gets converted to a two-terminal device in the box, and the way you match currents is by physical cell dimensions rather than [by trying to] suboptimize the diodes. The high-bandgap devices ( about 1.6eV) will be higher voltage and lower current than the low bandgap devices, which will be lower voltage, higher current, so you have a current-matched diode, and the best way to do that is simply to do it mechanically."

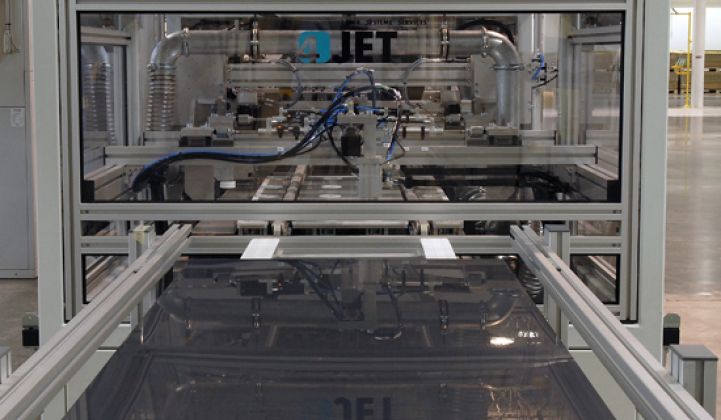

Stion uses sputtering to deposit the complex CIGS material system, in a manufacturing process that is rooted in the Camarillo Siemens/Shell process.

Khosla has suggested that Stion's differentiation was its tandem product "that can compete with all the incumbent silicon (not thin film) players by matching the efficiency of silicon cells with the costs of thin film." He added, "That upside gives the company 'legs' beyond the first few years of sprint, and I think every company needs to have a similar, short-term vector for future improvement. Otherwise, they will be resigned to the world of low-margin bloodbaths in an oversupplied market with few sustainable advantages."

Prior to Khosla assuming majority control, Stion had raised more than $200 million from Taiwan Semiconductor Manufacturing, Khosla Ventures, Lightspeed Venture Partners, AVACO, Korean private equity funds, Braemar Energy Ventures, and General Catalyst Partners. Khosla shared his thesis on thin-film solar with GTM in 2010.

More recent CIGS news

In September 2013, Saint-Gobain subsidiary Avancis curtailed production at its German CIGS thin-film solar factory. But the company is still working on CIGS technology in the lab and is setting new marks for conversion efficiency in this high-potential materials system.

The Torgau, Germany-based firm's CIGS module has hit an NREL-certified efficiency of 16.6 percent. According to the firm, that's a "new efficiency world record for encapsulated thin-film modules." First Solar hit 16.1 percent with its CdTe thin-film module in April 2013. (Note that the Avancis record is based on “aperture area” whereas First Solar is a “total area” measurement.)

Avancis' parent company Saint-Gobain operates a float glass plant in Torgau.

The hero module is 30 x 30 cm². The firm noted that "ZSW´s 20.8% efficiency on a laboratory cell...demonstrates the extraordinary potential of the CIS-based thin film technologies." Avancis uses a sputtering process to deposit the absorber layer.

Dr. Jörg Palm, head of process development at Avancis, said in a release, "The very good homogeneity of the CIS absorber properties based on production dimensions of 158 x 66 cm² were demonstrated by the minor deviation of 0.15% absolute between different 30 x 30 cm² modules from the same full-size absorber." The release continued: "The improvement in efficiency is based on the optimization of the buffer layer with respect to InxSy bandgap, band matching, and in particular transmission in a short wavelength range. In addition, the transmittance and the sheet resistance of the sputtered ZnO:Al front contact was optimized and the dead area between the series-connected cells was reduced by the use of picosecond laser process."

Siva Power, a relative newcomer to the CIGS material system, hit an NREL-certified 18.8 percent efficiency with its three-stage co-evaporation CIGS process, achieved in a claimed ten-month time span. The CIGS record holder, ZSW, holds a Fraunhofer-confirmed 20.8 percent efficiency for a CIGS thin-film solar cell, also built using the co-evaporation process.

Markus Beck, CTO at Siva, told GTM that the 0.5 cm2 sample "uses a thinner absorber (<2 micrometers) than ZSW, NREL or EMPA employ. This is to demonstrate that this is a truly manufacturable result. The voltage of the device is 711 millivolts, demonstrating the process capability; the same applies for the fill factor of 79 percent."

Siva CEO Brad Mattson said, "We plan to break the world record this year, and the trajectory indicates we have a good chance."

Mattson added, "One interesting point is that our average efficiency is relatively close to this maximum. In other words, we are not selecting an outlier to get a record. This indicates the process is more stable and repeatable than others think CIGS would be, more transferable to manufacturing. Also, we are doing this with a thin layer. We make it thin so we can hit our throughput numbers. So we are testing the process we want to transfer to manufacturing, not a specialized process designed to achieve records."

Siva also added solar energy expert Charlie Gay, Ph.D. to its Technical Advisory Board.

Hanergy Solar is set to "begin construction of a planned 3 GW CIGS thin-film manufacturing complex in Caofeidian, Hebei Province, China in March 2014, with tool install starting by the end of the year," according to a report on the website PV-Tech. Hanergy Solar claims that it will be launching a 300-megawatt line based on the MiaSolé CIGS sputtering process, as well as a 300-megawatt line based on Solibro’s co-evaporation process, at an estimated cost of $780 million for the two lines, according to reports.

Solibro's batch co-evaporation process and MiaSolé's roll-to-roll sputtering process are two very different processes requiring very different equipment sets.

Hanergy recently hit 19.6 percent conversion efficiency in the lab on a small area sample, as certified by the Fraunhofer Institute.

Solar Frontier announced its intention to construct a 150-megawatt CIS solar module plant, with production starting in 2015, in the Tohoku region of Japan. This will be the solar module manufacturer's fourth production plant and brings its total capacity to more than 1 gigawatt. Solar Frontier has hit conversion efficiency of 19.7 percent for a cell of 0.5cm² in area.

South Africa’s PTiP, a spinoff from the University of Johannesburg, commissioned a 5-megawatt pilot-production line for manufacturing CIGS solar modules using production equipment from Singulus Technologies.

Here's a partial list of CIGS solar players:

- Solar Frontier, with 577 megawatts shipped in 2011, is the only CIGS vendor of commercial consequence. Solar Frontier just shipped 86 megawatts of its CIS thin-film panels to EPC firm Chiyoda for use in a number of projects in Japan.

- Solibro, 95 megawatts shipped in 2011 (sold to Hanergy)

- MiaSolé, 60 megawatts shipped in 2011 (sold to Hanergy)

- Global Solar Energy (selling consumer solar, firm recently sold to Hanergy)

- Manz

- Avancis

- HelioVolt (Taken over by SK Innovation in 2011, closed in 2014)

- Ascent Solar (selling consumer solar, majority owner is TFG Radiant)

- Samsung (module record holder at 15.7 percent)

- Stion (limited commercial production, allied with TSMC, majority-owned by Khosla Ventures)

- SoloPower (dormant, searching for funding)

- Solarion (limited production on PI substrate)

- TSMC (technology licensed from Stion)

- NuvoSun (acquired by Dow)