Last year, we covered the launch of Gridco’s power electronics-based technology for controlling grid voltages and power quality down to the individual feeder lines that serve people’s homes. That’s very difficult to accomplish with today’s grid gear, making Gridco’s emPower solution potentially very useful for utilities struggling to manage the rising tide of rooftop solar energy flooding the edges of their grids.

That’s only if it works, of course -- and if it costs less than competing alternatives. Gridco hasn’t revealed cost or price figures for its in-line power regulator (IPR) devices or its distributed controllers and back-office support software, leaving the cost question unanswered as yet. But the Woburn, Mass.-based startup is now offering proof that it can do what it promised, in the form of testimony from two utility partners, California’s Sacramento Municipal Utility District and Ontario, Canada’s Greater Sudbury Hydro.

Gridco has been working with both utilities since early last year, deploying pole- and pad-mounted IPRs, the distributed grid controllers that perform computing and data processing tasks in the field, and its back-office software platform, Gridco CEO Naimish Patel told me at this week’s DistribuTECH conference. Both utilities wanted Gridco to show it could keep distribution grid circuits at rock-steady voltage set points, as well as handle other grid challenges, like canceling out the power factor fluctuations at the point where reverse power flow from solar inverters meets power flowing from the grid.

The results, Patel said, show that “it does its job, both under forward and reverse power flow, and it does so at whatever set-point they want. [It also] does it continuously -- unlike what you’d see with a tap changer or a capacitor bank, you don’t see bumps” in the voltage where physical devices are switching on and off, or from one set point to another.

What's more, “We showed the IPR’s multi-function capability allowed for power factor correction, which is important for PV,” he said. “When you see reverse power flow from PV -- and particularly where you’re at the point of net zero power flow -- you see wildly varying levels of power factor.”

Finally, Gridco is managing grid harmonics, he said. “In our architecture, we’re able to cancel both voltage harmonics, as looking downstream,” toward the end customer, “and current harmonics, as looking upstream” from where the grid meets the customer. Harmonics problems can be caused by solar inverters, particularly older (or cheaper) models that skimped on their components or design, he said. But they’re also coming from the laptop and cellphone power converters, variable frequency drives, LED light bulbs, and all the other digital “non-linear loads” being plugged in nowadays.

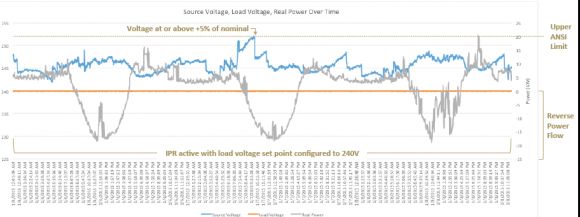

Here’s a chart that shows what Gridco did over two days on one distribution grid circuit -- one with a significant amount of solar power, according to the big midday surges in reverse power flow -- the gray line with the sometimes sunny, sometimes partly cloudy generation patterns. It’s pretty simple, despite the small type -- Gridco took what would have been a circuit with significant voltage fluctuations, including one potential maximum voltage violation, as shown in blue, and flatlined it to 240 volts, as shown in red.

Being able to tame voltages on problem circuits in this precise a manner could offer significant advantages over other technologies that tackle the problem in different ways. Volt/VAR optimization (VVO) and conservation voltage reduction (CVR) systems have been used for decades in a centralized fashion, changing set points at substations to try to keep voltages -- and thus, real power consumed -- within the lower reaches of what’s allowed under industry standards, typically 114 volts to 122 volts (PDF).

But centralized schemes are limited by the variability of the circuits that connect its customers, which can range from short, networked city blocks to mile-long cables connecting a handful of customers. Meanwhile, the growth of rooftop solar PV is causing circuit voltages not to sag, but to swell, requiring a device that can buck as well as boost voltage, he said.

Load tap changers, voltage regulators and capacitor banks are today’s tools for electromechanically changing voltages at the substation and feeder levels, and as these devices become more automated and networked, they are getting more useful for solving these new challenges. Companies like Utilidata and Dominion Voltage have been using grid-tied sensors and smart meters, respectively, to better inform CVR and VVO schemes and devices in the field.

There are also a number of alternative power electronics-based technologies being tested on the grid today, not least of which are the solar inverters themselves. Smart inverters can inject reactive power, control how fast they ramp up their power generation, and provide other grid supporting roles.

Finally, the same advances that have made solar inverters, battery power converters and electric vehicle motors more efficient over time have been put to use by companies like Gridco, Varentec and GridBridge, to build a new class of power electronics devices that digitally manipulate the electricity humming across distribution grid circuits. It’s taken some time for novel technologies like this to get to the pilot stage on real circuits, and they will certainly face long-term reliability and performance tests to come. But it’s good to see real-world evidence that they can do their job.