The race to make the best and brightest LED continues, this time in tube form. Philips, the Dutch lighting giant, announced Thursday that it has made an integrated LED system to replace the ubiquitous fluorescent tube lights we’ve all suffered under, one with an unprecedented 200 lumens per watt of high-quality white light in laboratory tests.

Getting that high performance out of commercially available products will be another matter, of course. LED competitor Cree announced a 200-lumens-per-watt white LED in December, but as a single-die emitter. Cree also has shown 276 lumens-per-watt single-die white light in lab settings. Typically, we’ve seen lab ratings drop significantly as products are moved to market, as the irregularity of materials supply and manufacturing process combine with a still-complex channel to get cutting-edge LEDs installed and working properly.

As for the fluorescent tube replacement, Samsung announced a then-record-setting 140-lumens-per-watt tube in September, with plans to introduce it first in Japan. Based on energy savings over time, Samsung claimed a two-year payback on its tubes, with up to twice the efficiency of the fluorescents they’re replacing.

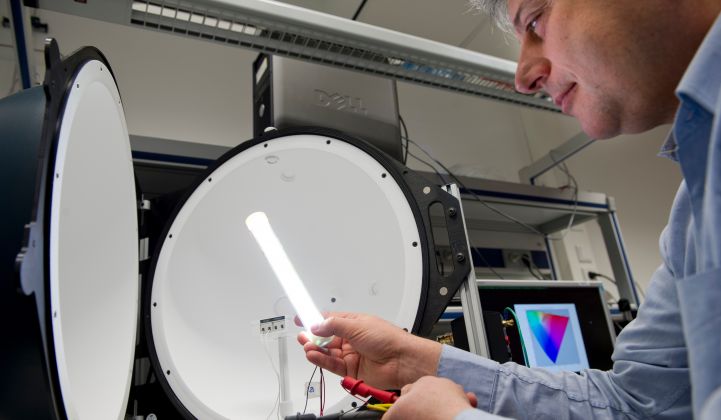

While Philips hasn't released any pricing or go-to-market specifics on its new tube LEDs, or TLEDs, the new 200-lumens-per-watt tubes are twice as efficient as its current models, and also produce a quality of light that surpasses others on the market, according to Jy Bhardwaj, senior vice president of research and development at Philips’ Lumileds LED division.

“The most important thing is, that when you generate that light, it’s got to be on the black body line,” Bhardwaj said, in explaining the highly subjective issue of lighting quality. The “black body line” describes the point at which various constituent colors -- in the case of Philips’ new tube, red, blue and green -- merge to form the most perfect white possible. Anywhere “off” the black body line, and the light has a color tint, he said.

Philips achieves a warm, 2700 Kelvin light, as compared to the more blue-tinged, higher "temperature” light from some competing TLED products, he said. To achieve this, Lumileds uses “very high-performance Lumiled blue and red LEDs, and remote phosphors” to convert blue light to green light, “integrating optics in a really innovative way, and managing the thermals and heat sinks to come up with an integrated solution,” he said.

Getting the colors right is only one part of the challenge -- managing the heat these light-emitting chips emanate is another big one. Philips has optimized its optics to lower the amount of power required, as well as to reduce the inefficiencies of converting it from color to color, in a way that also reduces heat, Bhardwaj said.

“The form factor and technology does translate to other applications very readily,” he added, meaning that we can expect to see other forms besides the tube, including the classic A-19 Edison incandescent light bulb, coming out in the near future.

Fluorescent tubes are a far more accessible commercial market, given that they’re found in commercial and institutional settings where lighting upgrades make a lot more bottom-line sense. Replacing all the overhead, flickering gas-filled tube lights in the United States with LEDs at Philips’ new claimed efficiency could cut their current estimated 200 terawatt-hours per year of energy consumption in half, for a savings of $12 billion or so, according to a 2012 Department of Energy study.

From the Philips News Center: