Moog Japan Ltd. has built a system that detects the stress on each of the blades of a windmill for power generation and adjusts the blade to an optimal pitch angle.

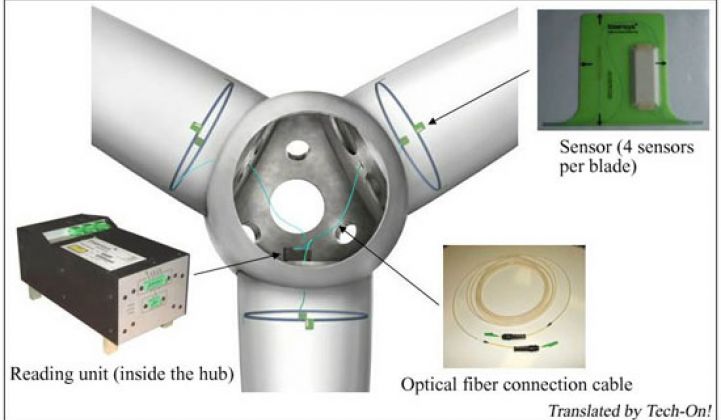

Four load sensors are installed at the base of each blade to measure distortion. The system adjusts the pitch angle to reduce the load on the wings when the wind is strong or when asymmetric load is applied on the windmill due to variations in wind strength. The adjustment will extend the lifetime of a windmill and reduce power generation cost.

The system uses sensors that incorporate a fiber bragg grating inside an optical fiber and detects changes in the grating space caused by distortion from changes in the light. It can measure distortions up to 4,500 μstrain (0.45 percent) at a resolution of 1 μstrain and 25 times per second.

To get the rest of the story, visit Tech-On!