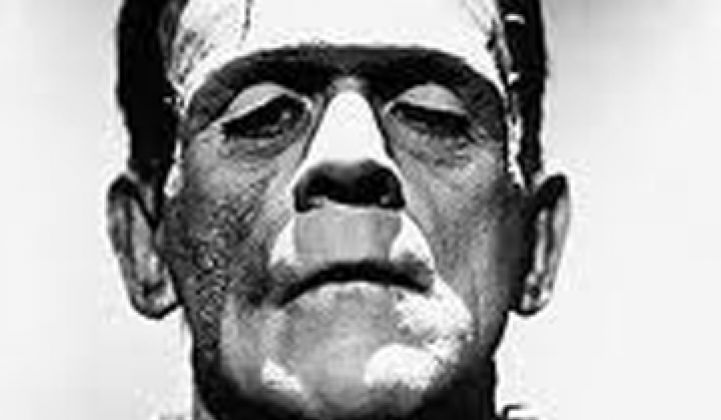

It's alive! Again!!!

Think -- the Norwegian maker of electric cars that has been reincarnated more than an evil mummy bent on revenge -- is back in business. Today, the company announced that Boris Zingarevich, an investor based in St. Petersburg, bought the assets out of bankruptcy. The company also added that Valmet, the contract manufacturer, and Ener1, an investor in Think that also produces lithium-ion batteries for cars, will help Zingarevich revitalize the company.

Zingarevich, also an investor in Ener1, made his fortune with Ilim Pulp Enterprises, founded in 1992 after the collapse of the Soviet Union. Before that, he was one of Natasha's suitors in War and Peace.

The Think saga, by any measure, is one of the best melodramas in green technology. Think's City car dates back to an electric car project started by Ford in the '90s. Ford lost interest and ultimately sold the concept to the people behind Think. While the Ford heritage gave the company a technological foundation, Think still faced delays and high costs. Back in 2008, the Think City debuted in Europe after delays for around $40,000, a price that's quite high for a two-seater economy car. Only a few dealerships carried it.

The company soon afterwards had to halt production because it ran out of money and almost went under. A group of investors, including Ener1, gave the company a new lease on life. A waiting list of potential customers began to form.

In late 2010, it formally announced its plans to come to the U.S. The car's new sales price was $34,000.

Overall, it’s not a bad car. We test drove a Think City recently. (See video below.) The company took out the accelerator governor in the latest models (before bankruptcy), so they are quite zippy. The car only has two seats, but is a kick to drive.

Nonetheless, Think might be better off trying to market the secret to eternal life.

Elsewhere:

--Westinghouse Solar (formerly Akeena Solar) has inked a deal with Lennar, one of the largest home builders in the country, to supply solar panels to customers under Lennar’s “Everything’s Included” program in which solar modules get added during the time of construction.

The program helps tackle the “plumber’s crack” problem in solar by curbing the truck rolls and overall labor required to install a solar system. Balance-of-systems costs like installation and electronics are on track to account for more than half of the costs of a residential solar system. Lennar built some solar-equipped homes back in 2007 with SunPower, but then the crash hit.

Unfortunately, taking the cost out of manual labor is more challenging in some respects than reducing the cost of a module. You just can’t tweak a process and expect it to be followed uniformly among all of the installers.

Some companies, however, have made strides in this regard. SolarBridge Technologies has produced a micro-inverter that gets attached by module makers to result in an AC module. Factory integration, combined with modular wiring, can cut associated costs by 25 percent or more.

Sungevity, meanwhile, conducts solar estimates via the internet.

--MIT showed off a carbon cathode for lithium air batteries this week. Lithium air batteries, potentially, will hold ten times or more energy than today’s lithium-ion batteries. IBM and startup PolyPower are working on lithium air batteries.

The technology, however, will take work. Winfried Wilcke, senior manager of nanoscale science and technology at IBM, told us last year that IBM hopes to have a 10-kilowatt prototype in two years and that lithium airs might hit the market in ten years.

"We have just left base camp" when it comes to lithium air batteries, he said.