Data centers may be more ubiquitous than indoor grow operations for marijuana, but the latter are as energy-intensive as the former, according to a new report by EQ Research.

Indoor grows can have an energy intensity of about 2,000 watts per meter, according to the report, A Chronic Problem. A 2012 study from Berkeley Lab found that indoor marijuana production could account for as much as 1 percent of U.S. electricity use, about half the energy consumed by data centers.

But the amount of total energy used by pot growers is, well, growing, even if the exact figures are hard to come by. Colorado estimated grow facilities used about 0.5 percent of the state’s electricity in 2014. The state’s utilities say that figure is growing by about 50 percent per year. Within the city of Denver, marijuana grow operations are using more than 2 percent of electricity. By 2035, the state of Washington expects marijuana energy use to exceed the energy draw of electric vehicles.

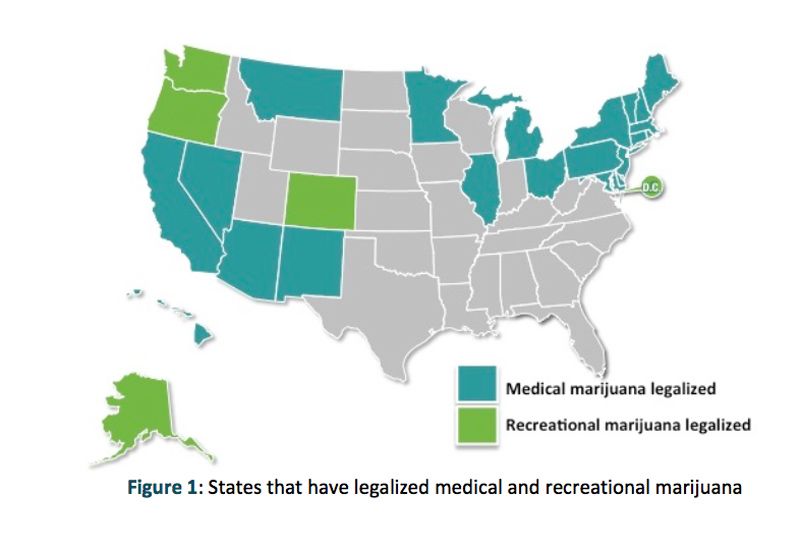

Source: NORML/EQ Research

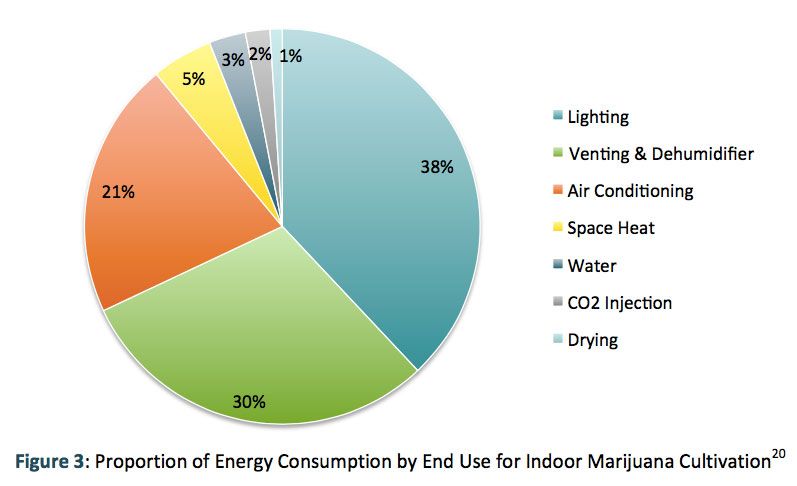

The energy use is mostly driven by lighting, venting and dehumidifiers. But unlike data centers, which are a focus of energy-efficiency efforts worldwide, the emerging marijuana industry exists in a legal gray area, which creates a barrier to these businesses taking part in state and utility-run efficiency programs.

Although anecdotal evidence abounds, “There is an information vacuum both about, and within, the marijuana industry,” the report finds. Utilities are often unable to or uncomfortable addressing the marijuana cultivation industry, and many growers, even if sanctioned by the state, do not want to share more information than they have to, given the industry's illegal status at the federal level.

Also, investing in more expensive LEDs and high-efficiency HVAC equipment upfront is often just not a consideration for growers who are already facing a litany of red tape in getting their operations off the ground. And while LEDs may offer superior performance in terms of efficiency and controllability, many growers simply aren’t familiar with them and prefer to go with the technology they are most comfortable with when launching their operations.

That means utilities need to engage growers early on, ideally during the planning phase of their operation, about options for more efficient equipment and what rebates may be available to them.

Source: Evergreen Economics, SDG&E Cannabis Agriculture Energy Demand Study

The report also recommends that utilities try to understand the industry better and design rates that that can help promote efficiency, just as some utilities have designed specific rates for data centers. Some public utility districts in Washington have offered cannabis-cultivation rates, with a daily system charge and non-coincident peak demand rate. A well-designed rate could also be beneficial for more than just marijuana growers.

Before setting rates, however, more data is needed, and that should be the focus of regulators, the study authors argue. In Denver, for instance, there is a Cannabis Sustainability Working Group that collects information on the industry and shares best practices with other stakeholders, such as utilities and government agencies.

Because the industry is so young, there is ample opportunity for regulators, utilities and the industry to be proactive about managing energy use. It must begin with collecting data.

“Marijuana trade associations may be able to provide utilities with generic, anonymized data on how energy is used in marijuana grows to help with resource planning and distribution engineering,” the study concludes. “Better information would help utilities with planning for power needs and also ease the process of getting marijuana grow facilities connected to the grid in the future.”