Although it's made partly from carbon dioxide, Novomer says that its plastic wrap will be better for food.

The company's polypropylene carbonate (PPC) – which consists of 50 percent fossil fuels and 50 percent carbon dioxide – provides a better barrier against oxygen than traditional PPC, which comes completely from fossil fuels. Ideally, that will allow food to stay fresher longer and prevent spoilage.

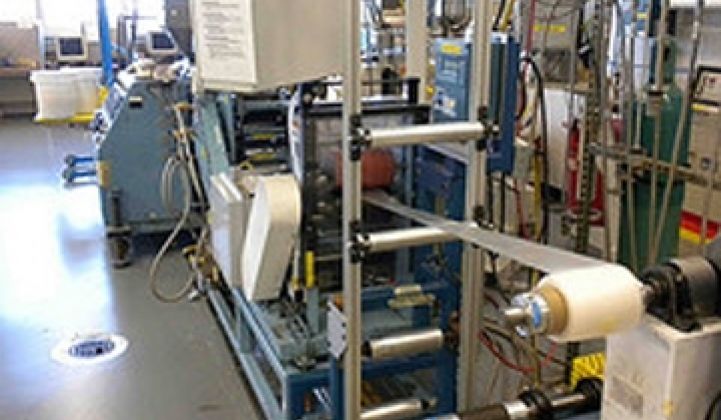

With help from Kodak, the world may be able to test that out in the near future. The company that once ruled the photographic market will built a pilot scale production facility with Novomer that will effectively let potential industrial customers obtain largish quantities of plastic wraps and coatings to test. Novomer, a spin-out of Cornell that raised $14 million in August, right now can only make very small quantities.

Ultimately, Novomer hopes to bring other types of plastics to the market. It could be swapped in for the acrylic currently used in those disposal diapers piling up in landfills.

There's a lot to like about this deal, and other similar deals between startups and industrial giants, like the one between green chemistry specialist LS9 and Proctor and Gamble. Currently, plastics manufacturing and plastics themselves consume about 10 percent of the oil in the U.S. If Novomer's process somehow went universal, fuel consumption could be dropped by 5 percent. The U.S. only has about 5 percent of the world's oil reserves so it's a significant gain. It could also bring the percentage of oil imports down from the current 65 percent plateau to where oil imports were in the middle of the decade. (Other companies, such as Axion International and Sollega, meanwhile, are devising ways to fashion products like building materials and solar racks out of somewhat cheap discarded plastic.)

It could also help foster economical carbon capture. When the technology is mature, Novomer claims it could be cost-competitive with fossil based plastics even without carbon capture, according to Mike Slowik, the strategic planning and analysis manager for the company. The material won't be as cheap as regular plastic, but manufacturers often have specific needs and formulas and will pay extra for companies that can meet their specific requirements. That is part of the reason you are seeing some biofuel companies emphasize green chemicals over fuel, which is more of a true commodity. If Novomer can thread the performance/price needle, it can definitely stay in any bidding wars.

"We can be competitive at scale without subsidies," he said.

Third, it could help revitalize jobs in hard-hit areas like upstate New York and the midwest. Finally, it could help manufacturers insulate themselves from commodity price swings.

But first, Novomer and Kodak have to prove it works.

The company's secret sauce is a series of chemical catalysts discovered by Cornell professor Geoffrey Coates that can prompt a reaction between epoxides (a fossil fuel material) and carbon monoxide or carbon dioxide at low temperatures and pressures. Right now, Novomer uses industrial grade carbon dioxide but it should be able to accommodate scrubbed gases from smokestacks.

By using Novomer's chemistry, the fossil fuel content in a polymer can be cut from 100 percent to 50 percent. Ultimately, the fossil figure might drop to zero. Researchers tried to devise similar catalysts for decades "but we are 30,000 times more efficient than they were in the '70s," CEO Jim Mahoney told us earlier this year.