Think of ChromaLit, the new LED technology from Intematix, as Garanimals for solid state lighting.

The company has devised a lighting system that makes the production of LED lights for offices or homes more economical by separating the LED chips (which emit blue light) from their complementary phosphors (which convert it into the white light you see emanating from bulbs).

Ideally, this sort of modularity will reduce the headaches and costs associated with stocking and manufacturing different lights, says CEO Mark Swoboda. A hotel wants 1,000 soft white 60-watt equivalent LED bulbs for its rooms? No problem -- the appropriately shaded ChromaLit components can be combined with a generic blue lighting canister. Tomorrow, 500 ceiling lights with an amber hue are needed in New York. With a little mixing and matching of components in the warehouse, you’re done.

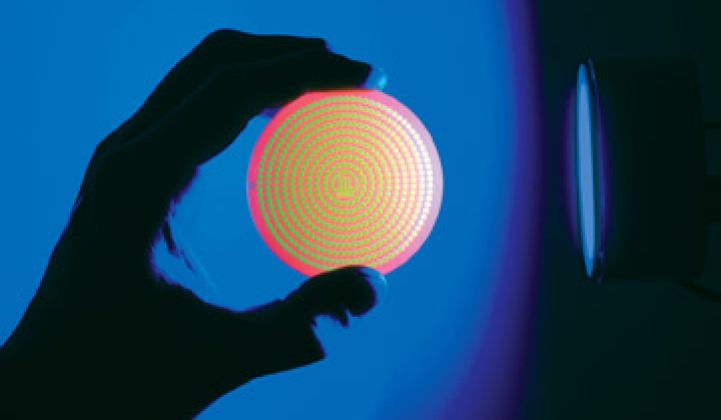

One or two canisters and a lot of phosphor lenses, and you have a multitude of possible combinations. The one in the photo emits white light but comes with a pattern that also lets some blue shine into the room.

“They never know what to make,” he said.

The company’s unusual technology and niche gives it an enviable spot in the booming world of solid state lighting. It has achieved a profit in four of the last six quarters and is growing at 50 percent a year, Swoboda said. Customers include Philips and other large companies.

Intematix may try to complete a mezzanine round of funding this quarter, said Swoboda, who also speculated that an IPO could occur in the next 12 months.

The company specializes in phosphors, which are chemical powders that are used to coat the inside of tube TVs, fluorescent bulbs and other devices. Intematix specializes in phosphors for LEDs.

Technically, phosphors create light, says Swoboda. A blue LED gives off light. That light then energizes the phosphor, which emits its own light.

“It is not a filter. A phosphor is the light source,” he says of Intematix’s products. “Instead of being excited by electrons, they are excited by blue light.”

The driver behind the company’s growth is that making LED chips revolves around electrical engineering. Manufacturers spend inordinate amounts of time wrestling with yields and chip efficiencies. Phosphors revolve around chemical engineering. It is the different discipline and the kind of thing that some have become willing to outsource.

Intematix sells phosphors for producing LEDs for televisions, industrial equipment, and general lighting. Traditionally, the phosphor-coated lens sits right above the LED chip and becomes part of the same component. The phosphors, by necessity, are printed and integrated at the factory.

Phosphors will likely remain part of the organic whole for LEDs used for TVs and industrial equipment: the performance specifications and color requirements are stringent.

In lighting, manufacturers have more leeway: the phosphor lens, via the ChromaLit system, can be fitted on in a warehouse.

Separating the phosphor lens from the chip has performance advantages, too. In the ChromaLit system, the phosphor lens and the chip no longer touch. In fact, two might be separated by an inch or more of air space (see video).

That air gap allows heat to dissipate, which increases the performance of both the chip and the phosphor lens. The system also reduces glare and increases light output. Fifty percent of the light from the phosphor ends up back in the can that holds the LED chips, but ultimately it bounces out.

The ChromaLit lens additionally acts as a natural diffuser, which cuts out the need for another component. The ChromaLit components can be made in a variety of shapes. The first ones will be flat disks that will slide over the top of small can lights. They can also be shaped into domes and be fitted over LEDs in an Edison bulb shape.

Another note: Intematix started out as an incubator for material science ideas. It looked at solar, etc. Many of these companies -- Nanosys comes to mind -- get bogged down by the enormity and variety of scientific tasks they’ve assigned themselves to examine. By narrowing its focus, Intematix could give this sector a better reputation.

Swoboda, by the way, has been in solid state lighting for a long, long time. Before Intematix, he was CEO of Bridgelux and also spent time at Lumileds.