CTZSS. It doesn't really roll off the tongue as easily as CIGS, but IBM says that its new solar cell could potentially lower the price of solar power in the future.

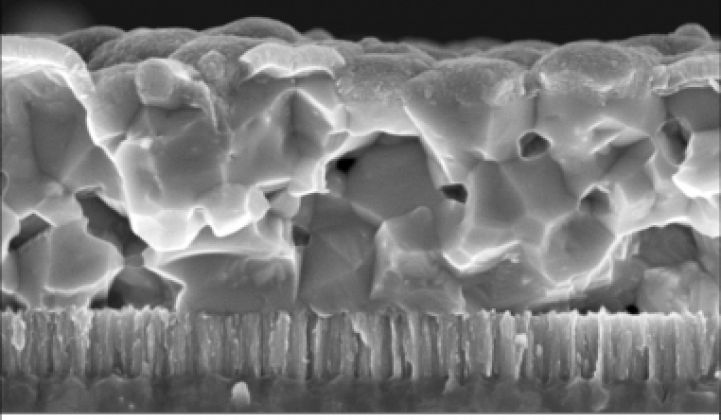

The solar cell is made from copper, tin, zinc, sulfur and selenium, all of which are somewhat earth-abundant, according to IBM. The test cell achieves a 9.6 percent efficiency, or around 40 percent higher than the 6.7 percent ceiling achieved by other, earlier cells made from the same materials. (That's a cross-section of IBM's Cu2ZnSn(S,Se)4 compound and not a dental X-ray.)

Big Blue did not use vacuum chamber processes (the sort of equipment used for chip-making) to produce it. Instead, it deployed a solution-based approach. In mass production, that could mean producing cells through printing or dip and spray coating.

The cell, in many ways, could be considered CIGS: The Sequel. CIGS stands for copper, indium, gallium, selenide. Some companies have also produced CIS cells, which stands for copper, indium sulfur. Overlap in materials exist, but note the absence of indium in IBM's process. Indium prices and availability have been an occasional source of criticism of the CIGS and CIS industry. Some analysts have also worried about commodity price spikes for the cadmium telluride solar cell industry. Zinc, by contrast, is extremely abundant.

Bringing such a cell to market, however, won't be easy. Investors have become nervous about championing new types of solar cells. Various CIGS companies also employ printing (Nanosolar) and other roll-to-roll manufacturing processes to produce thin film solar cells. It has taken most quite a while to iron out the kinks in the manufacturing process.

"In a given hour, more energy from sunlight strikes the earth than the entire planet consumes in a year, but solar cells currently contribute less than 0.1 percent of electricity supply -- primarily as a result of cost," said Dr. David Mitzi, who leads the team at IBM Research that developed the solar cell. "The quest to develop a solar technology that can compare on a cost-per-watt basis with the conventional electricity generation, and also offers the ability to deploy at the terawatt level, has become a major challenge that our research is moving us closer to overcoming."

How cheap? Well, we have calls into IBM. Stay tuned.

IBM, or its potential licensees, will benefit from the CIGS learning experience but will invariably have to grapple with technology issues to scale up to mass production.

Will IBM make solar cells? I'd guess not. IBM has for the past several years combed its vast research laboratories for technologies that could be used to advance solar, water, batteries and other clean markets. An IBM polymer devised originally for immersion lithography, the technique likely exploited to produce some of the chips inside your computer, is now being promoted as a material for producing membranes for desalination or producing power from osmotic pressure gradients.