Calls for data-center energy efficiency grow louder each year as massive computing warehouses approach the limits of available power.

Companies such as Google and Microsoft have responded by building facilities in unlikely settings, such as central Oregon, North Carolina and Iowa, where cheap, abundant energy from sources such as hydropower can be found. Iceland says its broadband links to North America and Europe and its abundant geothermal power make it an ideal location for large data centers.

But what about locating next to a dairy farm to take advantage of the energy in cow manure? The idea is not as far-fetched as it sounds.

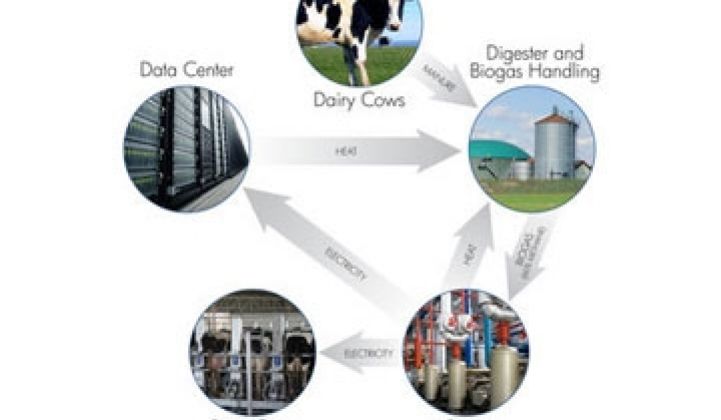

A team of Hewlett-Packard researchers crafted a blueprint for just such a system and say it could turn a profit in three years for an average-sized dairy farm. The system uses an anaerobic digester to turn manure into methane and recycles waste heat from a turbine to cool equipment and warm the bacteria inside the digester.

An average cow is good for around 100 watts of power a day, according to biogas experts, and it takes only a few weeks to turn manure into a syngas, which can be processed into methane. The methane can then be injected into turbines. Companies such as Microgy and BioEnergy Solutions have touted manure and digesters as sources for methane. BioEnergy has over 70,000 cows under contract for its digesters in California. Adobe has also studied the prospect of integrating biogas into the energy menu for its headquarters. That's a digester in the photo.

For nearly a decade, greening the world's data centers has been a focus of IT managers. A 2008 study from McKinsey found that an average data center uses the energy of 25,000 homes, with consumption in the industry rising 24 percent a year. Calculations show data centers now use 1.5 percent of all of the power consumed in the U.S.

"My goal is to develop a data center that consumes no net energy from the grid over its lifetime," says H-P Distinguished Technologist Cullen Bash. The dairy-farm plan is a step in that direction.

Bash describes the paper he and five colleagues presented Tuesday at the ASME 2010 International Conference on Energy Sustainability as theoretical. But he insists: "We think it is reasonable. All the components you need exist."

Bash calculates a farm large enough to install the system will have 10,000 dairy cows and an investment of $5 million. The outlay will pay for itself in two years and will generate a positive cash flow in the third, he says.

According to the blueprint, the digester turns 547 metric tons of daily manure into a gas that is 60 to 80 percent methane, or high enough quality to generate electricity. The fuel then powers a gas-fired generator and supplies electricity to the 1 MW center's IT equipment, its air-handling units, and refrigeration at the farm. Demand could reach 1.2 MW without the need to rely on the electric grid.

Waste heat from the generator is recycled to maintain digester temperatures, produce hot water and run a heat-absorbing chiller at the data center.

Bash says H-P researchers have explored various alternative power sources for data centers, including solar cells and wind turbines. But in some ways, the use of local farm resources makes the most sense. There's a synergy that benefits both with mutual reductions in CO2 emissions, he says.