The U.N. panel on climate change says we need to get a 50 percent reduction in global carbon emissions to prevent catastrophic climate change. With emissions still hitting record levels, achieving that target means decarbonizing in every way possible, including a 54 percent improvement in global energy efficiency.

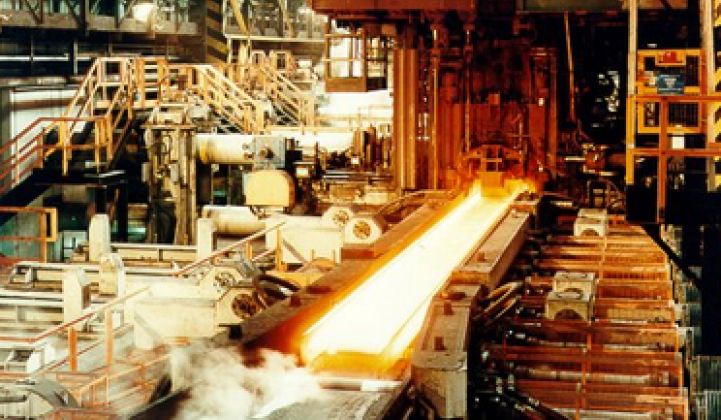

The manufacturing sector, which accounts for one-third of global energy use and 20 percent of carbon emissions, is a logical place to start. With materials like aluminum, cement, steel, paper and plastics making up half of the energy used in the production of goods, narrowing down to materials efficiency is an even better place to start.

But manufacturers may soon reach limits to reductions in material use, say two MIT researchers who just released a meta-analysis on production efficiency.

After examining various high-adoption scenarios for recycling, materials substitution, and cutting-edge production equipment (without regard to cost), the researchers concluded that a 25 percent to 40 percent reduction in emissions per ton of material produced is possible by 2050. With improvements in manufacturing techniques and the most ambitious recycling scenario, they predicted that a 50 percent reduction in emissions is possible by mid-century. This limit is largely due to the fact that it takes a minimum amount of energy to process materials -- the hard reality of thermodynamics.

Even with those constraints, achieving a 50 percent reduction in emissions would be pretty big.

"This would allow a doubling of global materials output with no increase in emissions, which would be a remarkable achievement," write the researchers.

That would help meet the doubling of material extraction and processing expected over the next four decades. But if we're going to realize an absolute reduction in emissions by 50 percent by 2050, it's going to take a more comprehensive approach to how we use and re-use materials.

So how can we break through the efficiency barrier outlined by these researchers? Here are three emerging ways that tackle the problem from a different angle.

The sharing economy

There's no doubt that we simply need to use less, particularly as emerging economies start mimicking the consumer culture pioneered by developed countries. Reducing consumption is the easiest way to cut back on demand for new materials without any radical advancements in technology. But telling people to just stop buying stuff isn't an effective way to change behavior. The sharing economy -- a model pioneered by Airbnb, Freecycle, GetAround, SnapGoods, Zipcar and many others -- has the potential to drastically reduce the purchase of new goods. For example, one study showed that for every vehicle in a car-sharing service, nine to thirteen private vehicles are taken off the road. It is still unclear how significantly sharing services can lower individual consumption economy-wide, but they do offer strong potential for limiting the production of new goods, thus saving materials upstream.

3-D printing

While still very much in its infancy, 3-D printing has the potential to shift production of goods from central manufacturing facilities to our own homes or businesses. The Department of Energy estimates that 3-D printing could cut energy use in manufacturing by 50 percent and slash material consumption by up to 90 percent. Additive manufacturing technologies can now print composites, metals and polymers to create an expanding range of products. Along with cutting back on wasted material by building products in layers, the process can also lower emissions by localizing production to the point of consumption. In addition, researchers estimate that remanufacturing components using this method would require only 25 percent of the energy needed to make new products.

M2M communications

Machine-to-machine communications capabilities are dramatically changing the way we optimize and interact with physical equipment. This connectivity has positive implications for how we run our manufacturing equipment, how the energy systems in a building operate, and how we get our goods to market. As a new report from the Carbon War Room shows, M2M technologies have the potential to reduce carbon emissions in the built environment by 1.6 gigatons in the next eight years, helping unlock $1 trillion in value. By gathering granular information about every piece of equipment operating along the production value chain, there is deep potential for delivering products to market using far less energy -- and creating far fewer emissions -- than today.

The laws of thermodynamics cannot be violated when it comes to producing materials. That puts limits on how deeply we can cut emissions. But new technological innovations changing the way we consume those materials can push those cuts even further.

To learn more about the Carbon War Report report, and to receive a complimentary copy, register for a free webinar on Leveraging M2M: The Need for Data in Energy Efficiency for Increased Performance and Monetization.