Palo Alto, Calif.--Talk about swords to plowshares.

In a lab experiment designed to see whether the company could play a role in the emerging market for airborne wind, Honeywell engineers concocted a design for a flying wind turbine that is capable of generating 2 megawatts, which is largely based on technologies from unmanned flying vehicles it makes for the Department of Defense. The body of the turbine derives from the Predator B, while the auto-navigation and other electronics come from spy drones like this and other devices.

It hasn't been built -- Honeywell has only produced a detailed computer simulation -- but the basic components exist and the design shows what might be possible.

"Technologically, it is not an issue," said Eric Blumer, director of advanced technology, engines and air management research at Honeywell, at the Airborne Wind Energy Conference taking place at Stanford University.

Expect to see more concepts like this. Airborne wind -- turbines that fly in the sky and harvest energy from atmospheric wind -- has the potential, say proponents, of reducing the cost of wind power. These turbines, hypothetically, could also generate power more consistently than ground-bound turbines as well because of the more consistent winds that are present higher in the atmosphere. (That's a picture of the simulation, by the way.)

Are there hurdles? You bet. Only small prototypes exist. Airborne turbines will have to survive strong gusts, ice and unpredictable weather, and neighborhood groups will likely object to multi-ton devices twirling over the earth connected to shock cords that measure a kilometer or more in length. Utilities, the main customers, also have their hands full with trying to get permits for conventional solar and wind parks. Still, if these devices work, it could become a growth market for aerospace companies like Lockheed Martin, Honeywell and Boeing. Many defense contractors have already moved into solar and smart grid: you can call it the Utility-Industrial Complex.

"A wind turbine costs $5 a pound. An aircraft costs $500 a pound," said Fort Felker, director of the National Wind Technology Center at NREL. "We want the low cost of turbines and the reliability of an aircraft."

The Honeywell turbine would measure 57 feet across and carry two one-megawatt turbines. In 34 MPH winds at 5,000 feet, the device would travel at 172 miles per hour and generate a megawatt of energy. The generator sits in the back of the device to add stability. The tether that connects it to the earth would come from Honeywell's material science division.

"Because of the trailing turbine, you have to work hard to go out of control," he said. If it became untethered, it would fly in lazy figure-eights. "This thing likes to fly. The stall speed is low," he added.

If it's so good, why doesn't the company go forward? For one thing, Wall Street analysts would beat them up.

"We can't do the VC thing. We have to go into established markets," he said. "Aerospace is a growth industry. If this grows it, we're all for it."

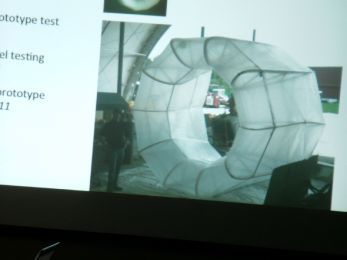

At the other end of the spectrum is the "shrouded turbine" from Alteros Energies, a company formed last December by MIT and Harvard students. It looks like an inflatable donut with a propeller in the middle. The shape of the device forces air through the opening and into the turbine; a similar turbo effect is being harnessed by the ground-based turbine from FloDesign, another company with MIT roots. It stays aloft because it's filled with helium. The lighter-than-air design means that turbines will cost 25 percent less than standard offshore turbines, according to co-founder Ben Glass.

Consumers also may feel more comfortable with a puffy, light structure that resemble the Stay-Puft marshmallow man from Ghostbusters or Bib the Michelin man floating over their heads than steel kites.

Conventional offshore wind, he added, is not cheap. Onshore wind turbines can now produce energy at around 9 cents per kilowatt-hour. Turbines in shallow waters offshore produce electricity for around 13 cents, and with turbines in deeper water, the price rises to 18 cents. The foundation used to secure offshore turbines can gobble up 25 percent of the capital.

Alteros has produced a design prototype (see photo) and hopes to have a structural prototype by next spring. If all goes well, it could have a working 100-kilowatt prototype in 2012.